High-silence door frame

A door frame and mute technology, which is applied in the direction of window/door frame, door/window accessories, sealing devices, etc., can solve the problems of not particularly good mute effect, loud noise, etc., achieve good mute effect, sound insulation effect, and improve the mute effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

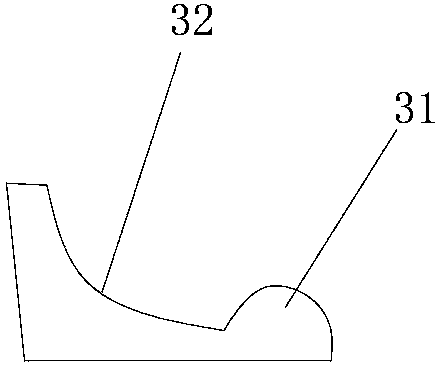

[0021] As shown in the drawings, a high-mute door frame includes a door panel step 1 and a door frame base 2, the door panel step 1 includes a step surface 11 facing the door body, and the door frame base 2 includes a step surface 11 connected to the base surface 21, the connection angle between the step surface 11 and the base surface 21 is provided with a rubber buffer mute strip 3, and the end of the rubber buffer mute strip 3 away from the step surface 11 is provided with a protrusion There is a first buffer block 31, and a second buffer slope 32 is provided at a position corresponding to the connection angle between the step surface 11 and the base surface 21 of the rubber buffer sound-absorbing strip 3 . The included angle between the step surface 11 and the base surface 21 is 98 degrees. The raised height of the first buffer block 31 is 3 mm.

Embodiment 2

[0023] The difference from the above embodiment is that the included angle between the step surface 11 and the base surface 21 is 95 degrees. The raised height of the first buffer block 31 is 5 mm.

Embodiment 3

[0025] The difference from the above embodiment is that the included angle between the step surface 11 and the base surface 21 is 100 degrees. The raised height of the first buffer block 31 is 1 mm.

[0026] The first buffer block 31 can buffer the door body for the first time, and decelerate the door body for the first time. The second buffer slope 32 can make the door body perform a second buffer deceleration before hitting the step. As the body keeps closing, the thickness of the second buffer slope in contact with the door body becomes larger and larger, the buffering effect is more obvious, and the mute effect is better. Moreover, the extrusion of the door body by the first buffer block 31 and the second buffer slope 32 greatly enhances the sealing performance of the door, and the effects of smoke prevention, dust prevention and sound insulation are better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com