Anti-floating construction method and device for large-diameter cast-in-situ bored pile steel reinforcement cage

A technology of bored cast-in-place piles and construction methods, which is applied to protection devices, sheet pile walls, infrastructure engineering, etc., can solve the problems affecting the construction quality of bored (punched) cast-in-place piles and the floating of steel cages, and achieve the anti-floating effect. Obvious, low input cost, easy to make and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

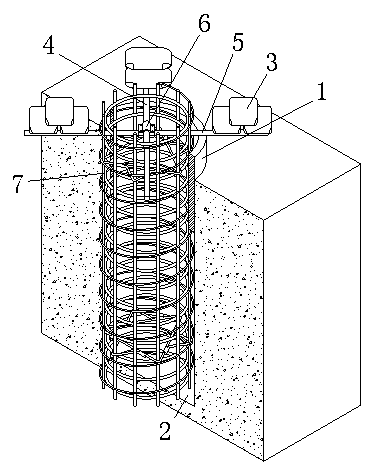

[0017] Embodiment of the present invention: when implementing a kind of large-diameter bored cast-in-place pile reinforcement cage anti-floating construction method of the present invention, as figure 1 As shown, the method is to vertically place the welded reinforcement cage 7 in the large-diameter borehole 2 cast-in-place pile, and the top of the reinforcement cage 7 is higher than the height of the large-diameter bore hole; a steel pipe frame is arranged on the top of the reinforcement cage, and A counterweight 3 is set on the steel pipe frame; then pouring construction is carried out, and the counterweight 3 is used to prevent the reinforcement cage 7 from floating during the pouring process, so as to ensure the pouring quality of the reinforcement cage of the large-diameter bored pile. The weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com