Floating prevention device for ground source heat pump buried pipe

A technology of ground source heat pump and underground pipe, which is applied in the directions of geothermal energy, geothermal energy power generation, geothermal collector, etc., can solve the problems of buried pipe depth change, floating, affecting the heat exchange efficiency of ground source heat pump, etc., and achieve the effect of preventing floating Good, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

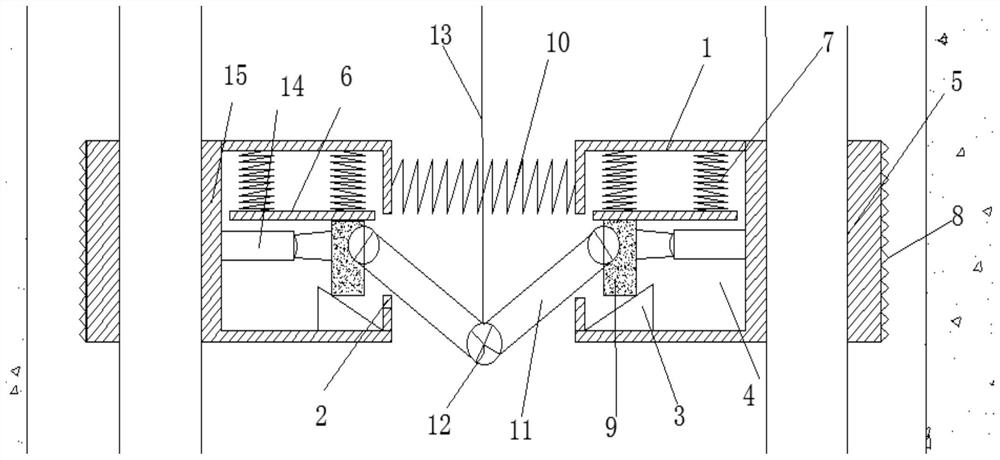

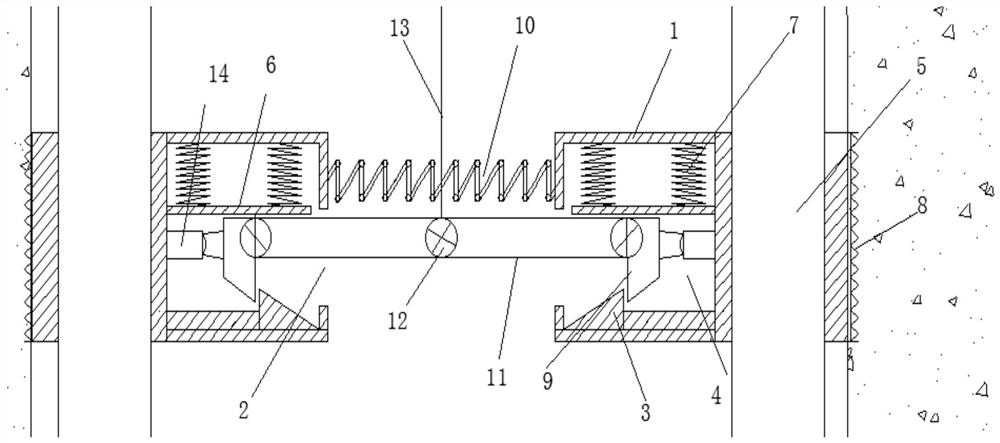

[0028] see figure 1 and Figure 4 , including a set of fixed frames 1 and a first spring 10 connecting between the fixed frames 1;

[0029] A cavity 4 is provided in the fixed frame 1, and a baffle plate 6 is horizontally provided in the cavity 4, and the baffle plate 6 is connected with the inner upper wall of the cavity 4 by a second spring 7, and the cavity 4 is A slope block 3 is provided at the bottom, and a block 9 is provided between the slope block 3 and the baffle plate 6;

[0030] One side of the stopper 9 is respectively hinged struts 11, two ends of the struts 11 away from the stopper 9 pass through the opening 2 provided on the inner cavity and are flexibly connected by a connecting shaft 12, and the other side of the stopper 9 It is connected with the side wall of the inner cavity 4 through a short rod 14;

[0031] A sling 13 is fixedly connected to the connecting shaft 12;

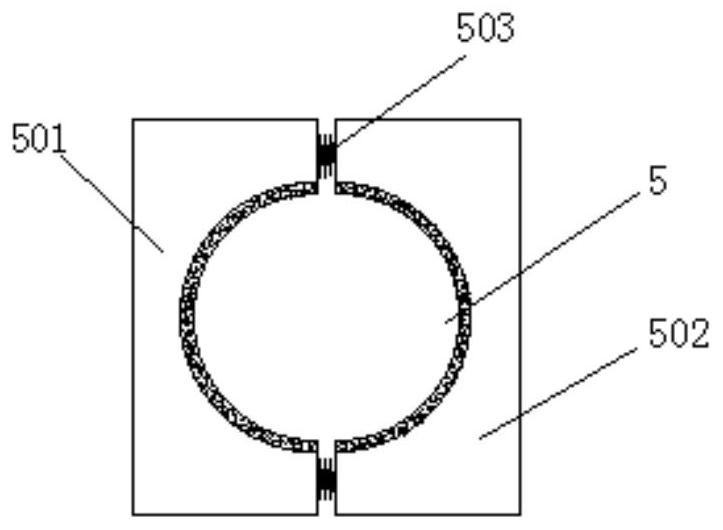

[0032] The fixed frame 1 is connected to a fixed block on the side away from it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com