An integrated drainage assembly and washing machine

A technology for drainage components and washing machines, which can be applied to other washing machines, washing devices, textiles and paper making, etc. It can solve the problems of complex production process, high production cost, and clogged drains of washing machines, so as to reduce installation costs, compact structure, and reduce noise The effect of drainage energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

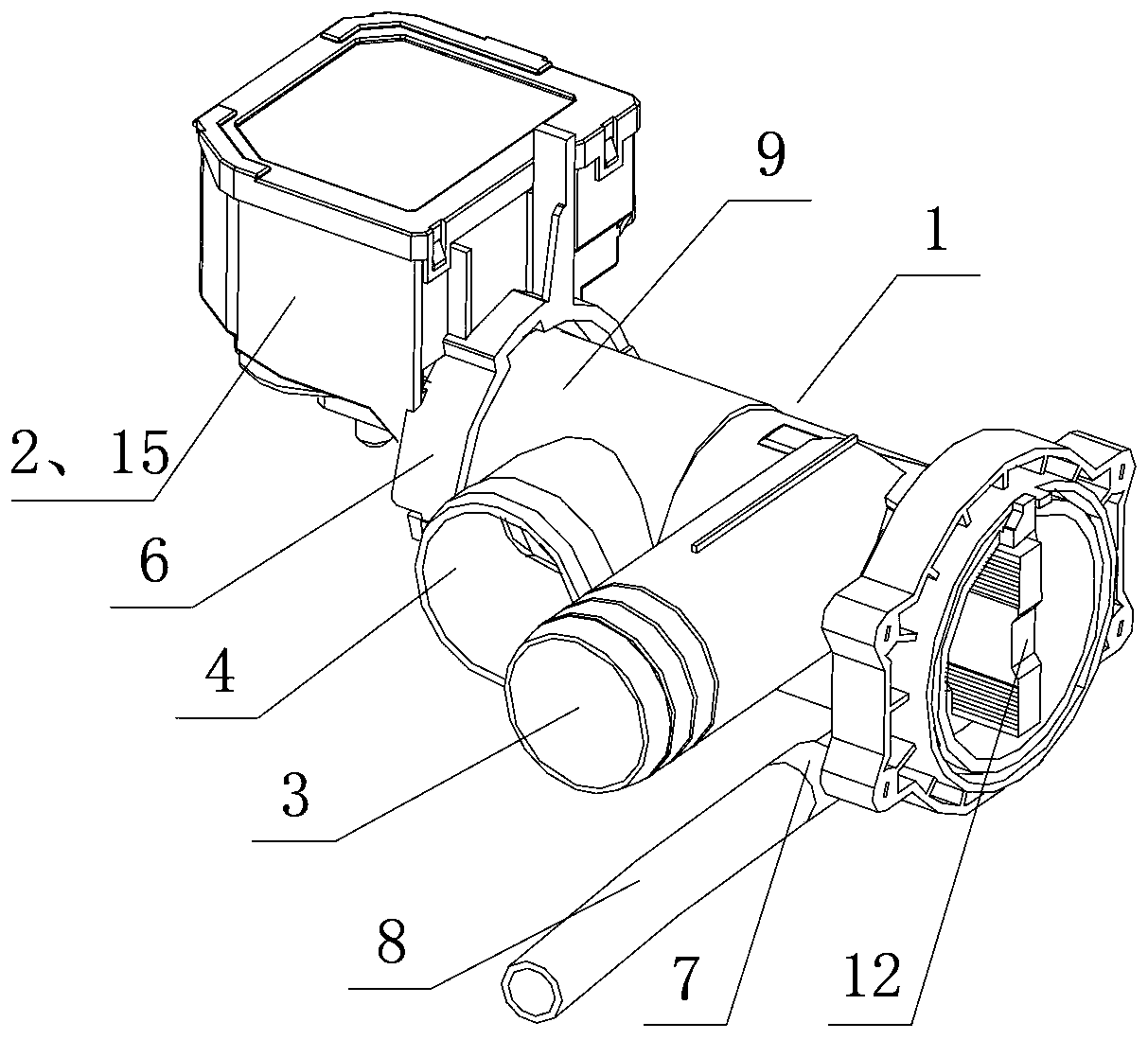

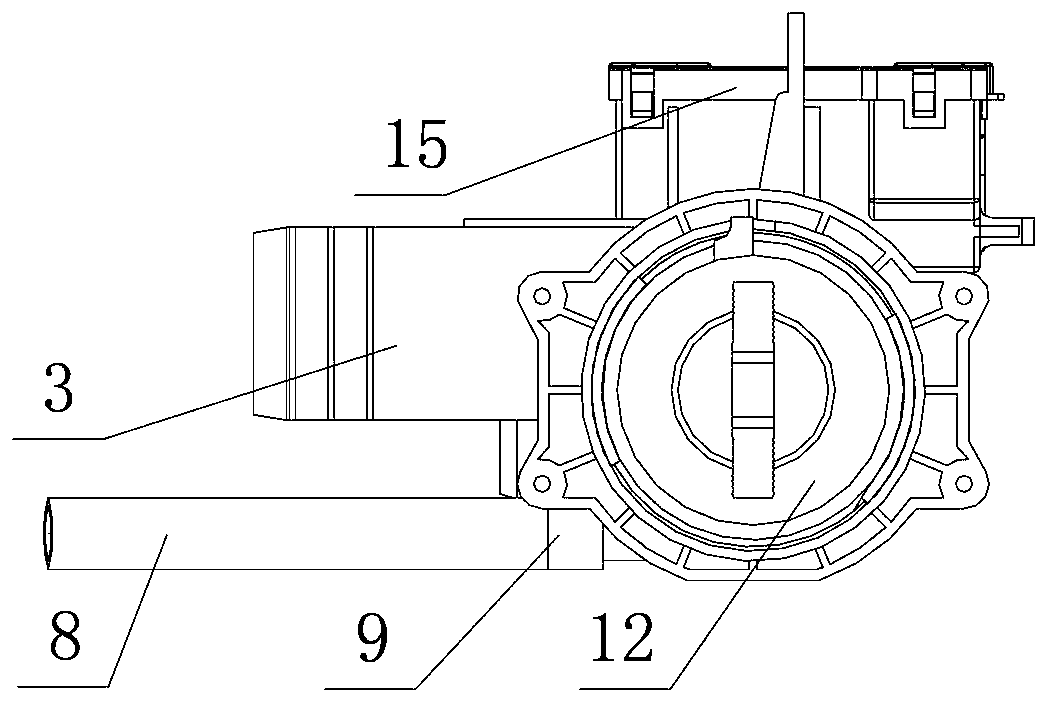

Embodiment 1

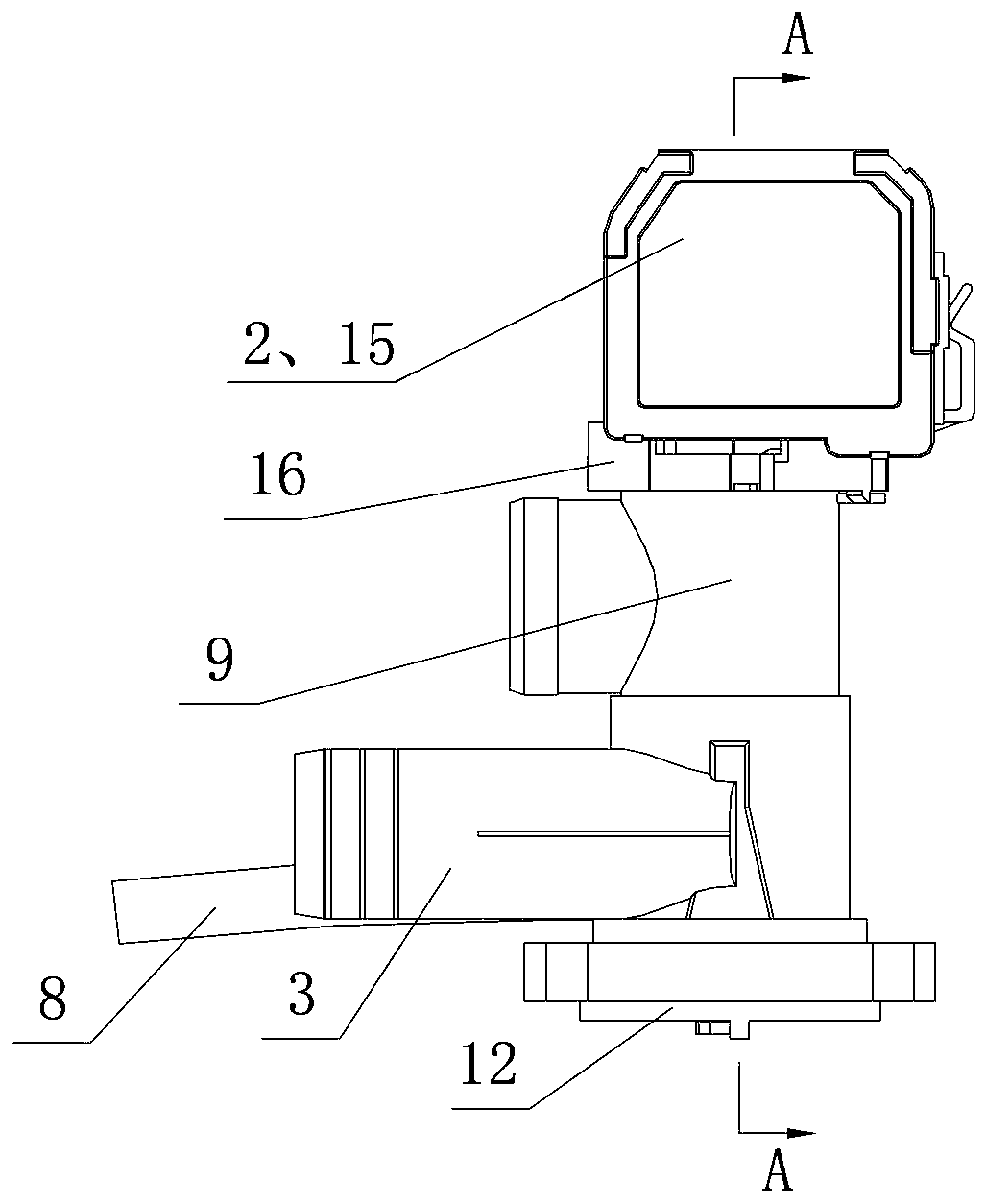

[0040] In this embodiment, a clasp is provided between the filter chamber 13 and the valve plug chamber 14 in the valve body 9 of the integrated drainage assembly. One end of the valve plug 6 is in contact with the snap ring, and the other end is connected to the drainage motor 2. With a return spring, when the drainage motor 2 is not powered on, the valve plug 6 is pushed against the snap ring due to the action of the return spring, thereby closing the water outlet 4. After the drainage motor 2 is powered on, the valve plug 6 is pulled away from the filter chamber 13 Direction movement, the return spring is compressed, so that the valve plug 6 is separated from the snap ring, so that the water outlet 4 is opened, and the water flows through. , close the water outlet 4.

[0041] The water inlet 3 and the water outlet 4 are distributed on the same side of the valve body 9, and may also be distributed on both sides of the valve body 9, depending on the installation position of the...

Embodiment 2

[0044] In this embodiment, the inner diameter of the valve body 9 of the valve plug chamber 14 is smaller than the inner diameter of the valve body 9 of the filter chamber 13 , and a boss is formed at the sudden change in the inner diameter. One end of the valve plug 6 is in contact with the boss, and the other end is connected to the drainage motor 2. There is a return spring inside the valve plug 6. When the drainage motor 2 is not powered, the valve plug 6 is pushed against the boss due to the action of the return spring. , so that the water outlet 4 is closed, and the drainage motor 2 is energized to pull the valve plug 6 to move away from the filter chamber 13, and the return spring is compressed, so that the valve plug 6 is separated from the boss, so that the water outlet 4 is opened, and the water flows through. The drainage motor 2 is powered off, and the restoring force of the return spring resets the valve plug 6 to withstand the boss and close the water outlet 4.

...

Embodiment 3

[0047] In this embodiment, the filter 5 is a lint filter, which can filter foreign objects such as lint and coins to prevent the blockage of the water outlet. The filter 5 is detachably connected to the valve body 9 of the drain valve 1, which is convenient for the filter 5. The disassembly of the filter 5, at regular intervals or when the user feels that there may be foreign objects such as wire crumbs and coins in the filter 5, the filter 5 can be removed and cleaned to avoid blocking the drain pipe of the washing machine.

[0048] The filter 5 includes a filter body 11 and a filter cover 12, the filter body 11 and the filter cover 12 are fixedly connected, and the filter cover 12 and the valve body 9 of the drain valve 1 are screwed or clamped Buckle card connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com