Blocking structure for air heating furnace bottom air leakage

A realization method, a technology of a hot blast stove, applied in furnaces, blast furnaces, heating furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A 1260m under construction in 2012 3 In the blast furnace project, during the trial operation, it was found that there was air leakage at the bottom of the three hot blast stoves, which would bring safety hazards to future production. The air leakage was calculated to be 1m 3 / min, the maximum temperature outside the furnace body is 55°C, and the working pressure of the furnace body is 0.3MP. In this regard, the company organized technical personnel to discuss the solution, and under the advice of relevant domestic technical experts, used high-grade cement mortar for secondary furnace bottom grouting Repair test, but the effect was not satisfactory; later, anhydrous phenolic resin repair technology developed by a famous domestic steel factory was used, but it failed because of poor material density, cracks in the material, or weak bonding between the sealing material and the metal body. Aiming at this specific working condition, after repeated research and experiments, ...

Embodiment 2

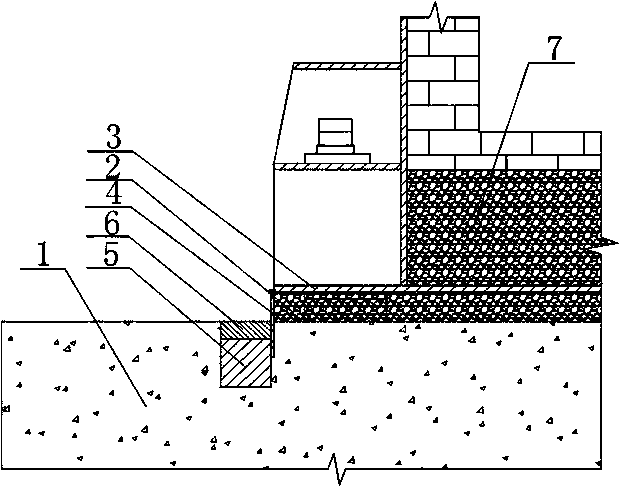

[0041] Such as figure 1 As shown, according to the structure obtained by the method of Example 1, the model of the groove is 80mm wide * 100mm, and the model of the steel plate 4 is 150mm wide * 10mm thick, and its length is equal to the 3 circumferences of the bottom of the hot blast stove. According to actual construction process, different models can be used, there is no need to stop production of the hot blast stove, and there is no need to operate the inner structure 7 of the hot blast stove. The gap enters the gap between the shim iron and the filling layer 2, and is sealed in the cavity formed by the steel plate 4, the concrete foundation 1, and the furnace bottom 3 of the hot blast stove. The gap between the steel plate 4 and the concrete foundation 1 can be realized by using a sealing material Sealing, the bonding between the bottom sealing layer 5 made of SHB planting glue and the steel plate 4 is very firm, the thickness of the bottom sealing layer 5 is 80mm, accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com