3D printer and printing method thereof

A 3D printer and print head technology, applied in the field of 3D printers, can solve problems such as high cost and complex structure, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

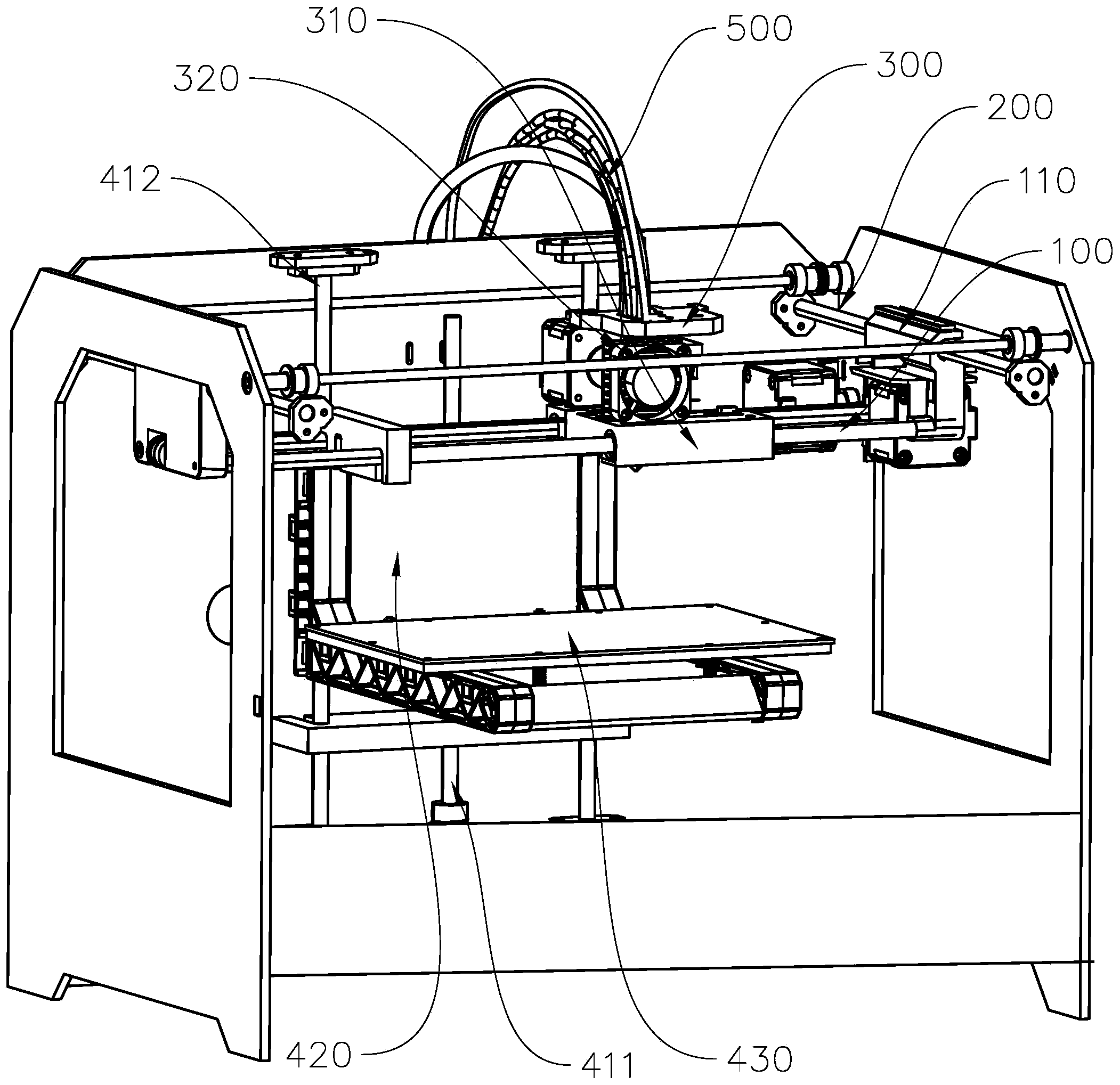

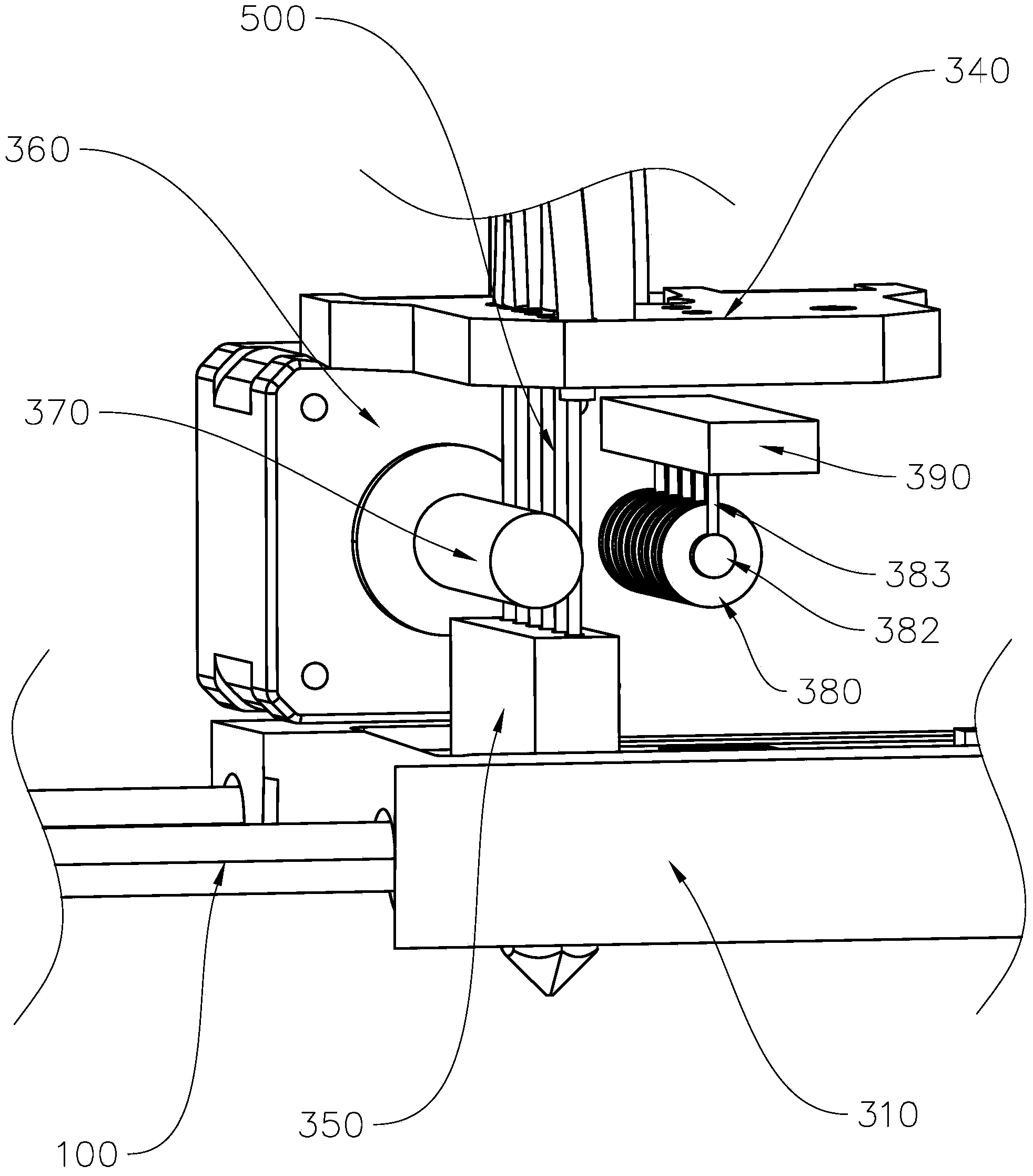

[0031] Such as figure 1 As shown, the 3D printer in this embodiment has a horizontal track, and the horizontal track includes an X track 100 and a Y track 200 . The X track 100 is connected to the Y track 200 through the first connecting frame 110 , and the X track 100 can move along the Y track 200 . The 3D printer has a print head 300 for extruding molten materials. The 3D printer has a Z track that moves vertically, and the Z track has a threaded rod 411 and two fixed rods 412, and the second connecting frame 420 passes through the threaded rod 411 and two fixed rods 412 are fixedly connected on the Z track, the end of the bottom of the screw rod 411 is provided with a motor, the platform 430 is fixedly connected on the second connecting frame 420, and the platform 430 is a molten metal extruded by the print head 300. material carrier. Under the rotation of the motor, the screw rod 411 rotates, and the platform 430 can move up and down in the vertical direction driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com