Single-needle type micron-sized object picking and releasing device and method

A pick-and-place device, micron-level technology, used in workpiece clamping devices, manufacturing tools, etc., can solve problems such as failure of micron-connected object picking tasks, achieve stable release, solve release problems, and compliant picking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

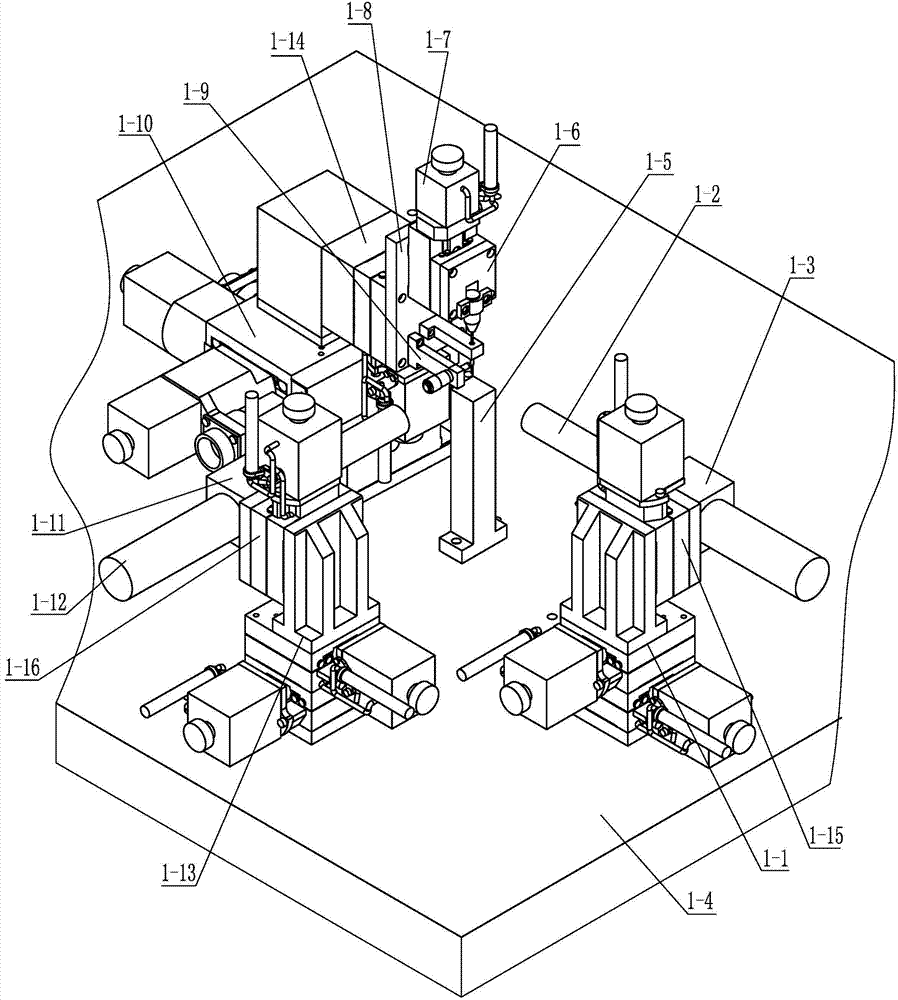

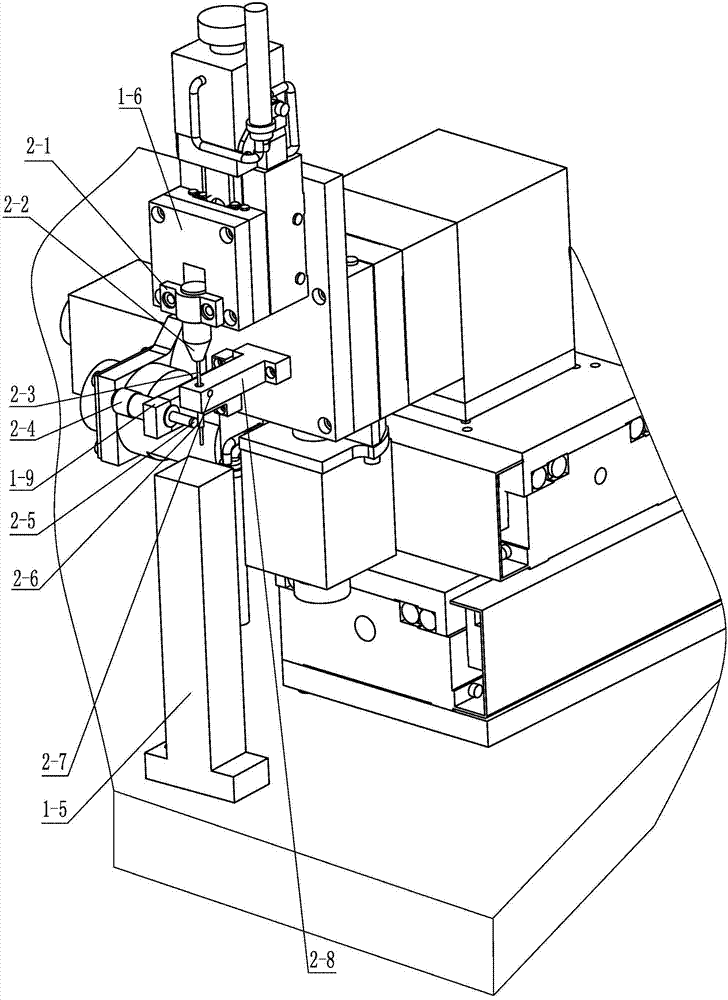

[0016] Specific implementation mode one: combine figure 1 and figure 2 Explain that a single-needle micron-scale object pick-and-place device in this embodiment includes No. 2 three-axis electric translation platform 1-1, vibration isolation table 1-4, No. 1 three-axis electric displacement platform 1-10, No. 3 three-axis Axis electric translation stage 1-13, self-tightening chuck 2-2, probe 2-3, screw micrometer head 2-4, thermistor element 2-5, capillary 2-6 and capillary clamp 2-8;

[0017] The No. 1 three-axis electric translation stage 1-10 includes a second connecting plate 1-6, a probe driving motor 1-7, a first connecting plate 1-8, a micrometer fixture 1-9 and a first connecting seat 1-14 ; No. 2 three-axis electric translation stage 1-1 includes No. 1 microscope 1-2, No. 1 microscope fixture 1-3 and second connection seat 1-15; No. 3 three-axis electric translation stage 1-13 includes No. 2 microscope 1 -12, No. 2 microscope fixture 1-11 and the third connecting s...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 2 Note that the capillary 2-6 of this embodiment is bonded to the lower part of the capillary holder 2-8. With such arrangement, the connection is convenient and reliable, and it is convenient to use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 2 Note that the thermistor element 2-5 in this embodiment is a thin-film platinum resistance element. In this way, the liquid medium between the micro-object and the probe disappears, and then the separation of the micro-object and the probe is realized. A PT100 with an overall size of 2mm×2mm×1mm (length×width×height) and a maximum operating temperature of 500°C can be selected. Type thin film platinum resistance element. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com