A kind of aluminum alloy hollow profile extrusion die

A hollow profile and extrusion die technology, applied in metal extrusion die and other directions, can solve the problems of high Al-Zn-Mg alloy viscosity, high flow stress, low die life and other problems, achieve high flow stress, improve stress, The effect of improving the life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

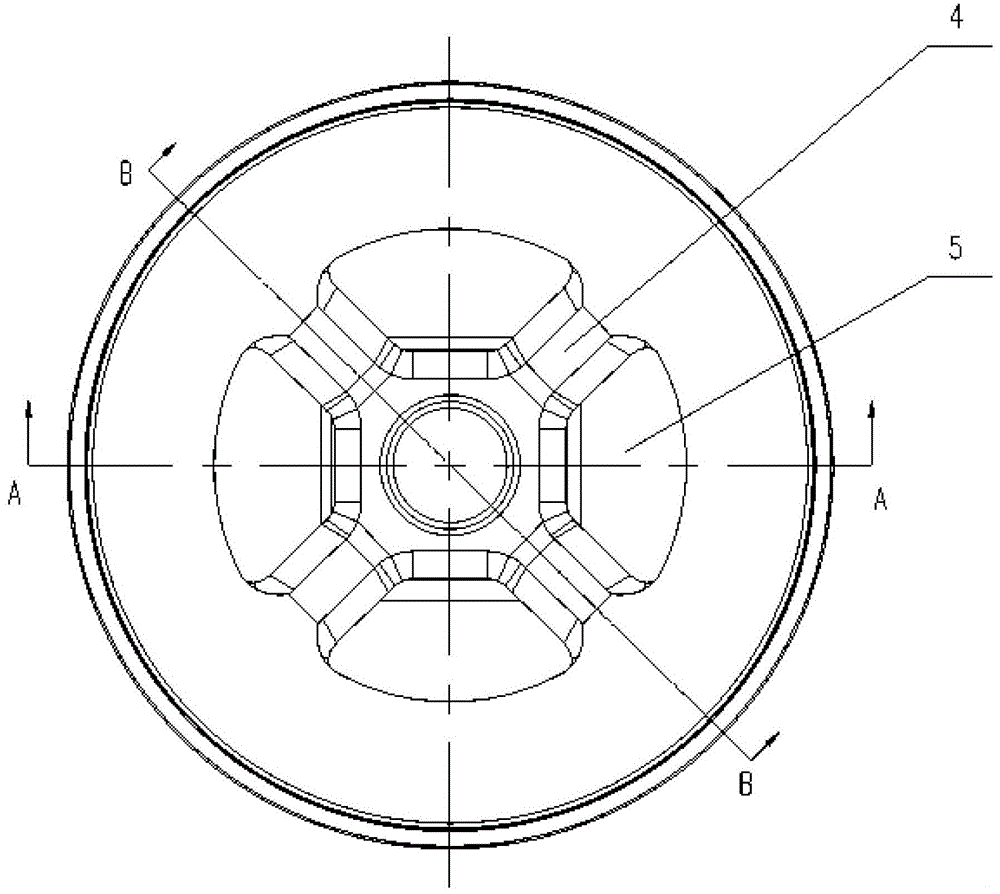

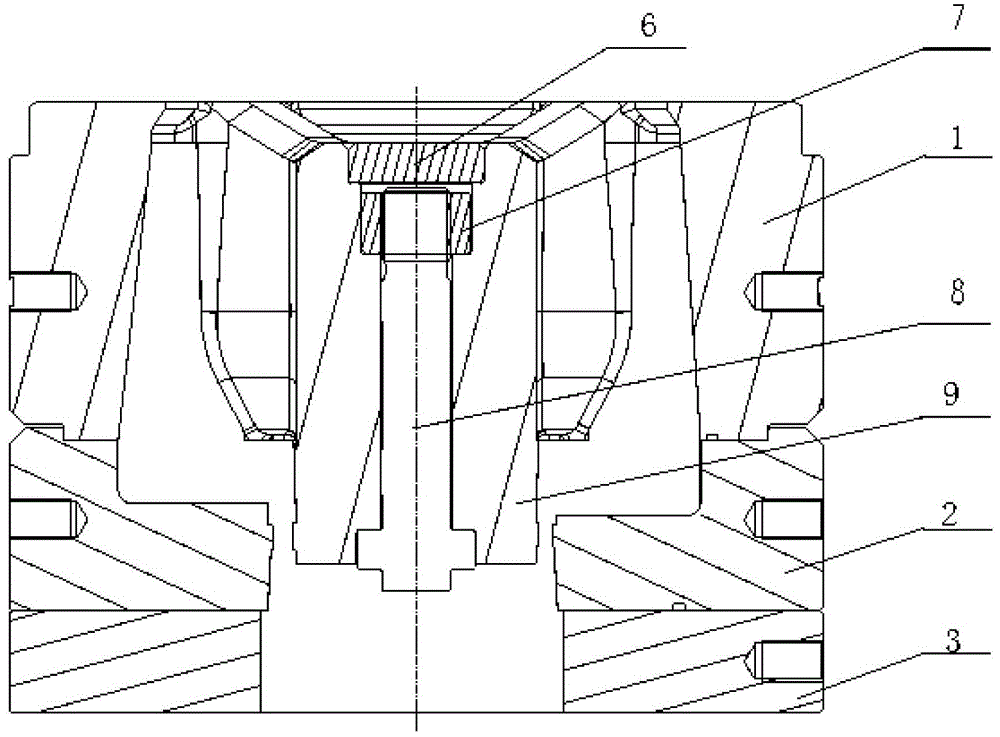

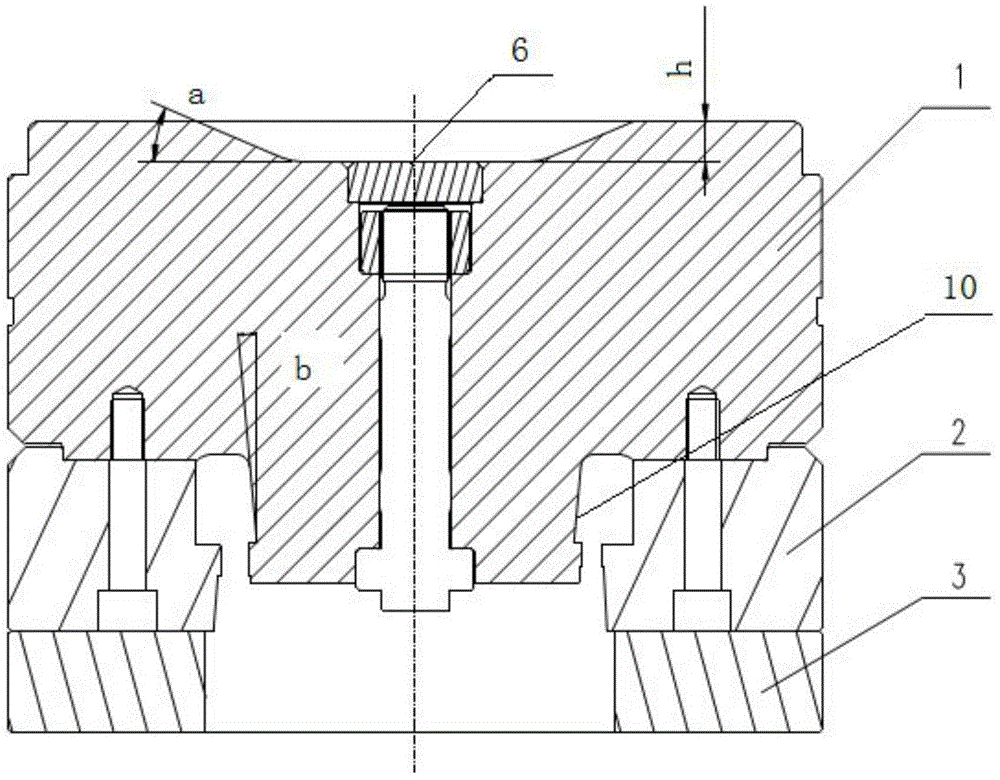

[0021] The invention discloses an aluminum alloy hollow profile extrusion die, which comprises an upper die 1 and a lower die 2 superimposed front and back. The feed surface of the upper die 1 is evenly distributed with a plurality of shunt bridges 4, and a shunt flow is formed between adjacent shunt bridges 4. Hole 5, the shunt bridge 4 connects and supports the core head 9 located in the center of the upper mold 1; the core head 9 is provided with a through hole along its central axis, and a matching rod is provided in the through hole, and the two ends of the rod are formed Squeeze both ends of core head 9.

[0022] Aiming at the problems that Al-Zn-Mg alloy has high viscosity and large flow stress, it is most likely to crack in the exit direction of shunt bridge 4 and core head 9, and the mold life is low, the invention adopts the design of dispersing extrusion force. That is, a through hole is arranged along the central axis of the core head 9, and rods with matching size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com