Extrusion forming mold

An extrusion molding and die technology, applied in the direction of metal extrusion dies, can solve the problems of easy cracking of the die, and achieve the effect of solving easy cracking, improving environmental adaptability, improving adaptability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

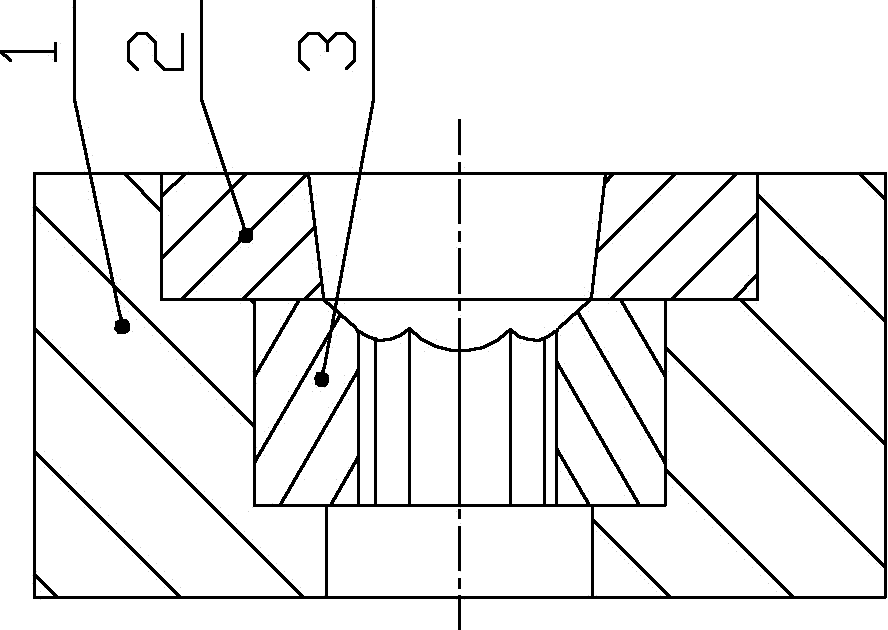

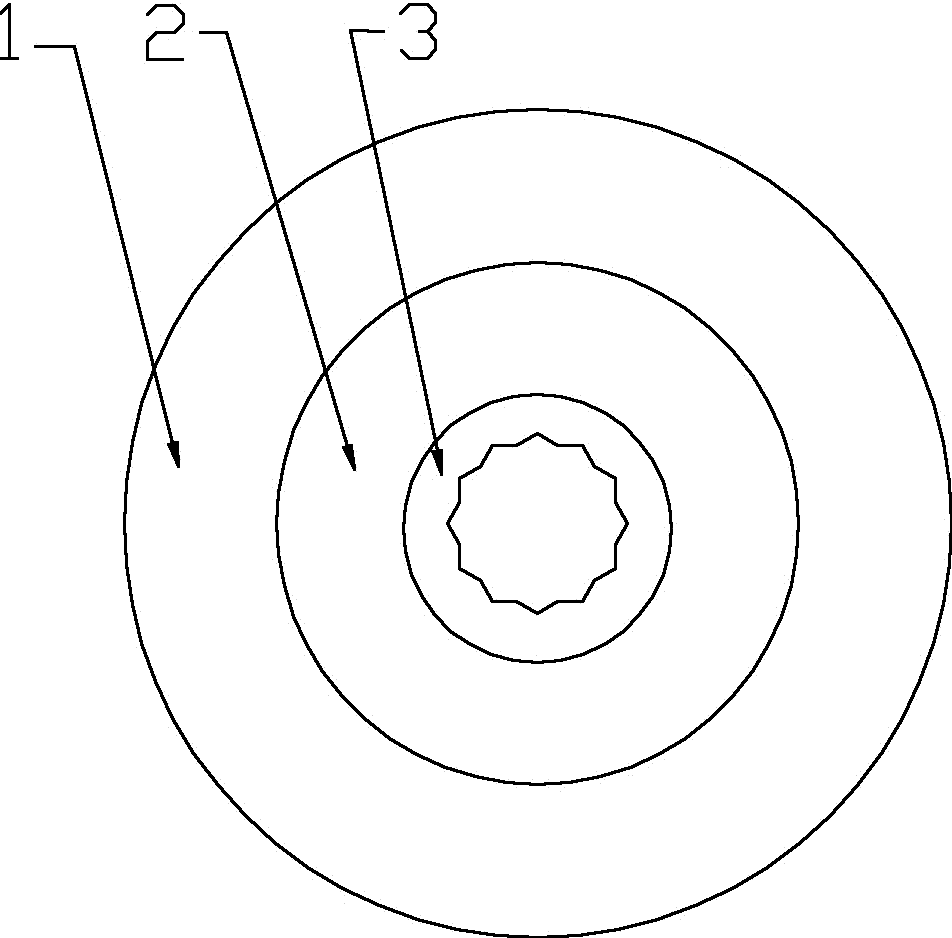

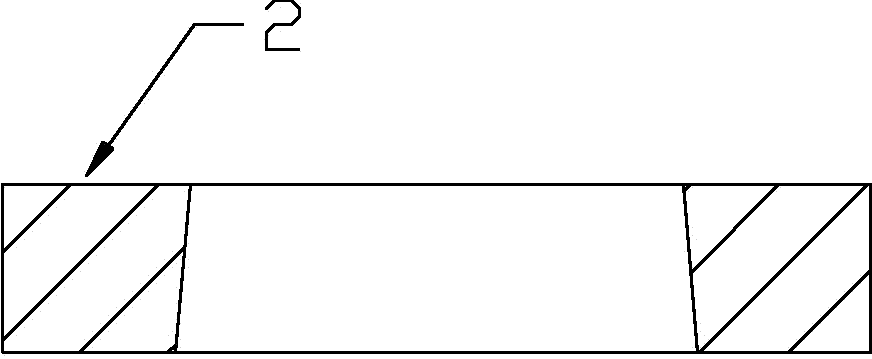

[0032] Embodiment 1 of a kind of extrusion mold of the present invention, as Figure 4-8 As shown: the extrusion mold includes a mold cover 11 , a mold core 13 and a mold sheet 12 . The mold sleeve 11 is provided with an inner cavity that runs through the upper and lower directions, and the inner cavity is stepped. The inner cavity includes a die cavity, a core cavity, and an opening in the axial direction. Assembled in the cavity of the mold piece, the mold piece 12 and the mold core 13 are correspondingly provided with a mold hole and a mold core hole extending in the vertical direction, and the mold core hole and the mold hole are connected. The mold core hole is a polygonal hole, and in this embodiment, the polygonal hole has twelve edges, which are twelve-sided holes. The outer peripheral surface of the die 12 is sleeved with an elastic ring 14. The elastic ring 14 has an inner peripheral surface elastically supporting the outer peripheral surface of the die 12 and an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com