Method for designing tire die on basis of Excel and CAD (computer aided design) platform

A design method and tire mold technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as improper cooperation between designers and production personnel, heavy workload, difficulty in ensuring work efficiency and work quality, and avoid molds. The effect of machining process design and process sheet compilation workload, reducing machining workload, and weakening drawing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Combined with specific design examples and accompanying drawings Figure 1 to Figure 6 Concrete processing technology of the present invention is described in further detail:

[0021] Step 1: Generate mold standard drawings, use the CAD electronic drawing software platform to draw the structural parts diagram of the relevant mold and the plane three-view of the general assembly drawing according to the production needs, and mark the parameters, and the marked parameters are all the parameters standard value notation for names;

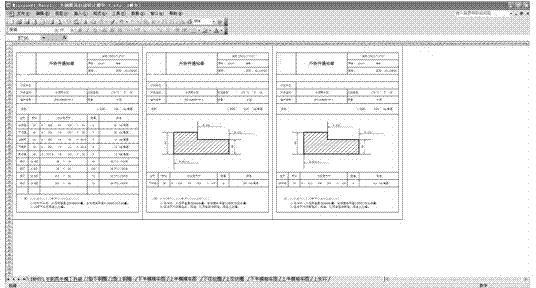

[0022] Step 2: Establish the Excel platform data processing library, create a spreadsheet document based on Excel2000, and then establish the data worksheet, production bill of materials worksheet, general assembly drawing worksheet and parts corresponding to the part drawing in this document Processing procedure worksheet, and establish data correction workspace and assembly drawing display area in the data worksheet, and design and establish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com