Passive driven electrophoresis type electronic paper device and driving method of passive driven electrophoresis type electronic paper device

A technology of electronic paper and electrophoresis, applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems that it is difficult to meet the production demand of mass products, increase the production process and manufacturing cost, and cannot meet the display accuracy requirements, so as to reduce the processing technology and equipment configuration requirements, low manufacturing cost, and the effect of avoiding the influence of display content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

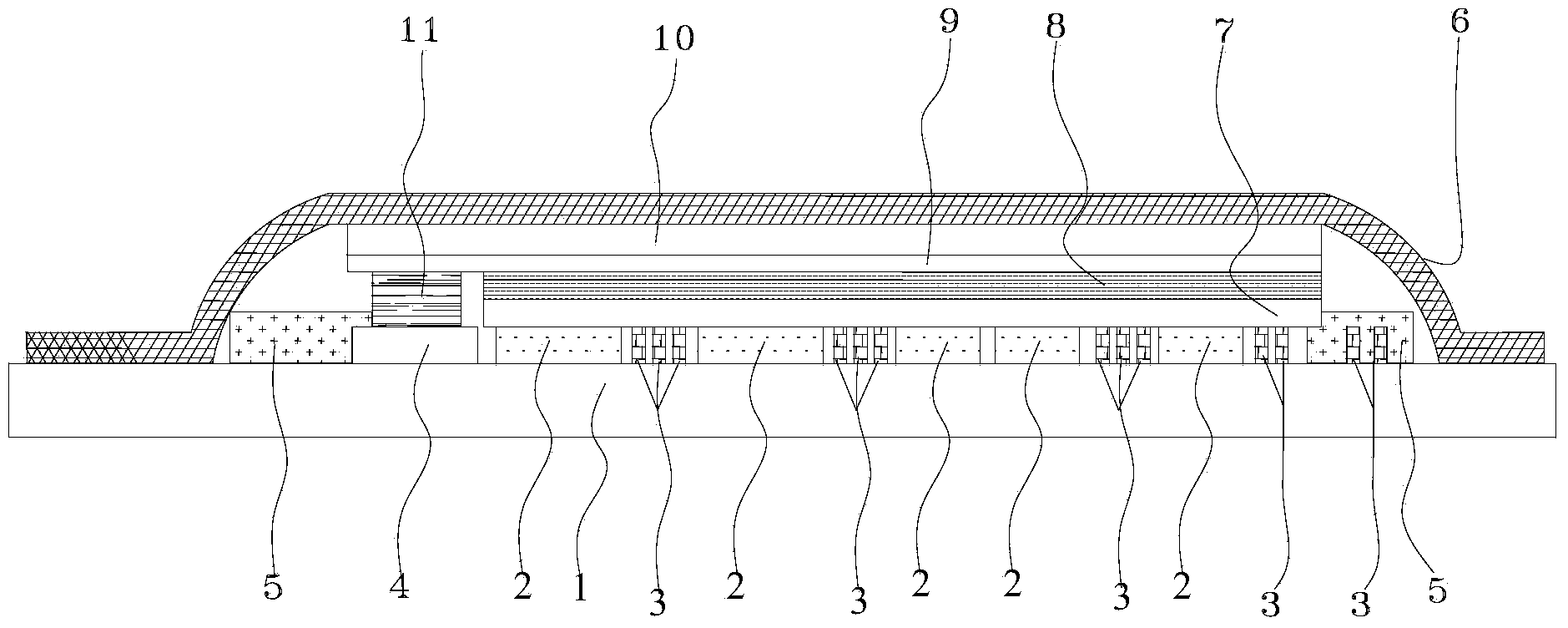

[0024] Such as figure 1 A passively driven electrophoretic electronic paper device shown includes: a display medium layer 8 and an upper substrate 10 and a lower substrate 1 oppositely arranged; a common lead electrode 4 and a display lead electrode 3 are formed on the upper surface of the lower substrate 1 and the display electrode 2; the lower surface of the upper substrate 10 is formed with a common electrode 9; the common electrode 9 is electrically connected to the common lead electrode 4 through the transfer electrode 11; the display electrode 2 is connected to the display lead electrode 3 The display electrode 2 and the display lead electrode 3 are connected to the display medium layer 8 through the glue layer 7, and the display medium layer 8 is accommodated between the glue layer 7 and the common electrode 9; the display An electric field is formed between the electrode 2 and the common electrode 9, which is sufficient to drive the display of the display medium layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com