Multi-core plastic optical fiber connector system

A plastic optical fiber and connector technology, applied in optical fiber transmission, cladding optical fiber, light guide, etc., can solve problems such as inability to support ultra-high-speed signal transmission, and achieve the effects of promoting popularization, reducing manufacturing costs, and neat and beautiful wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: A ring-shaped multi-core plastic optical fiber system.

[0046] This embodiment provides a multi-core plastic optical fiber connector system with a ring network topology, including duplex and simplex implementations.

[0047] Figure 5 Shown is a circular duplex multi-core plastic optical fiber connector system including 6 multi-core plastic optical fiber transceiver modules 101-106 and 6 multi-core plastic optical fibers, each of the 6 multi-core plastic optical fibers 13 is connected to two different The multi-core plastic optical fiber transceiver module, the multi-core plastic optical fiber transceiver modules 101-106 and 6 multi-core plastic optical fibers are sequentially connected to form a closed ring structure.

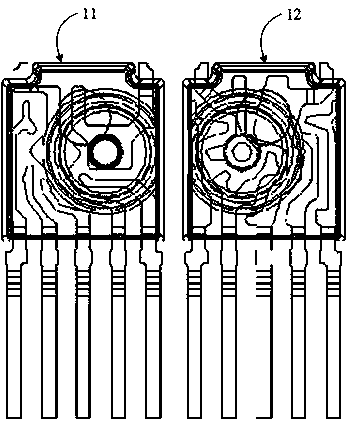

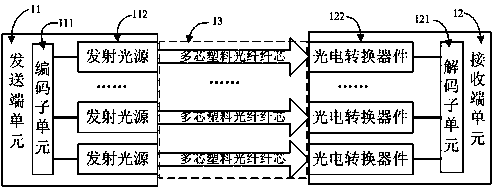

[0048] Each multi-core plastic optical fiber transceiver module includes a multi-core plastic optical fiber sending end unit 11 and a multi-core plastic optical fiber receiving end unit 12, and the multi-core plastic optical fiber sendi...

Embodiment 2

[0060] Embodiment 2: A star-shaped multi-core plastic optical fiber connector system.

[0061] The duplex multi-core plastic optical fiber connector system provided in this embodiment includes multiple multi-core plastic optical fiber transceiver modules, multiple multi-core plastic optical fibers and a multi-core plastic optical fiber interface switch, and each multi-core plastic optical fiber transceiver module They are all connected to the multi-core plastic optical fiber interface switch through a multi-core plastic optical fiber to form a star structure; the multi-core plastic optical fiber is a plastic optical fiber including multiple cores, and the multi-core plastic optical fiber interface contains a built-in multi-core plastic optical fiber Fiber optic transceiver module.

[0062] Figure 7 The illustrated embodiment takes a star-shaped multi-core plastic optical fiber connector system including four multi-core plastic optical fiber transceiver modules 201-204 as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com