Double-roller washing machine

A washing machine and double-drum technology, applied in the field of washing machines, can solve the problems of increasing the cost of the washing machine, the effect of shock absorption and noise reduction is not obvious, etc., and achieve the effect of being suitable for popularization and use, obvious shock absorption effect, and reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

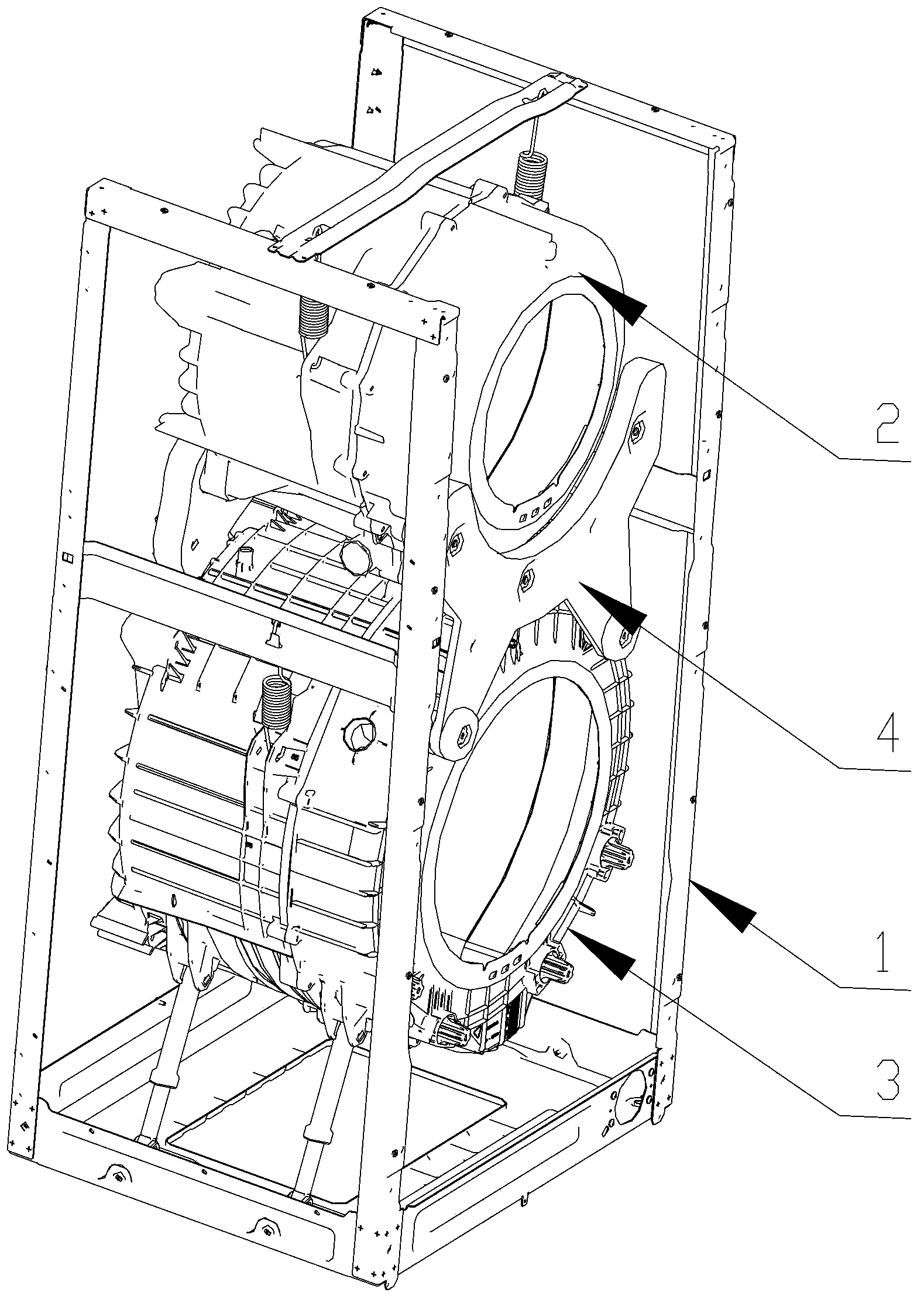

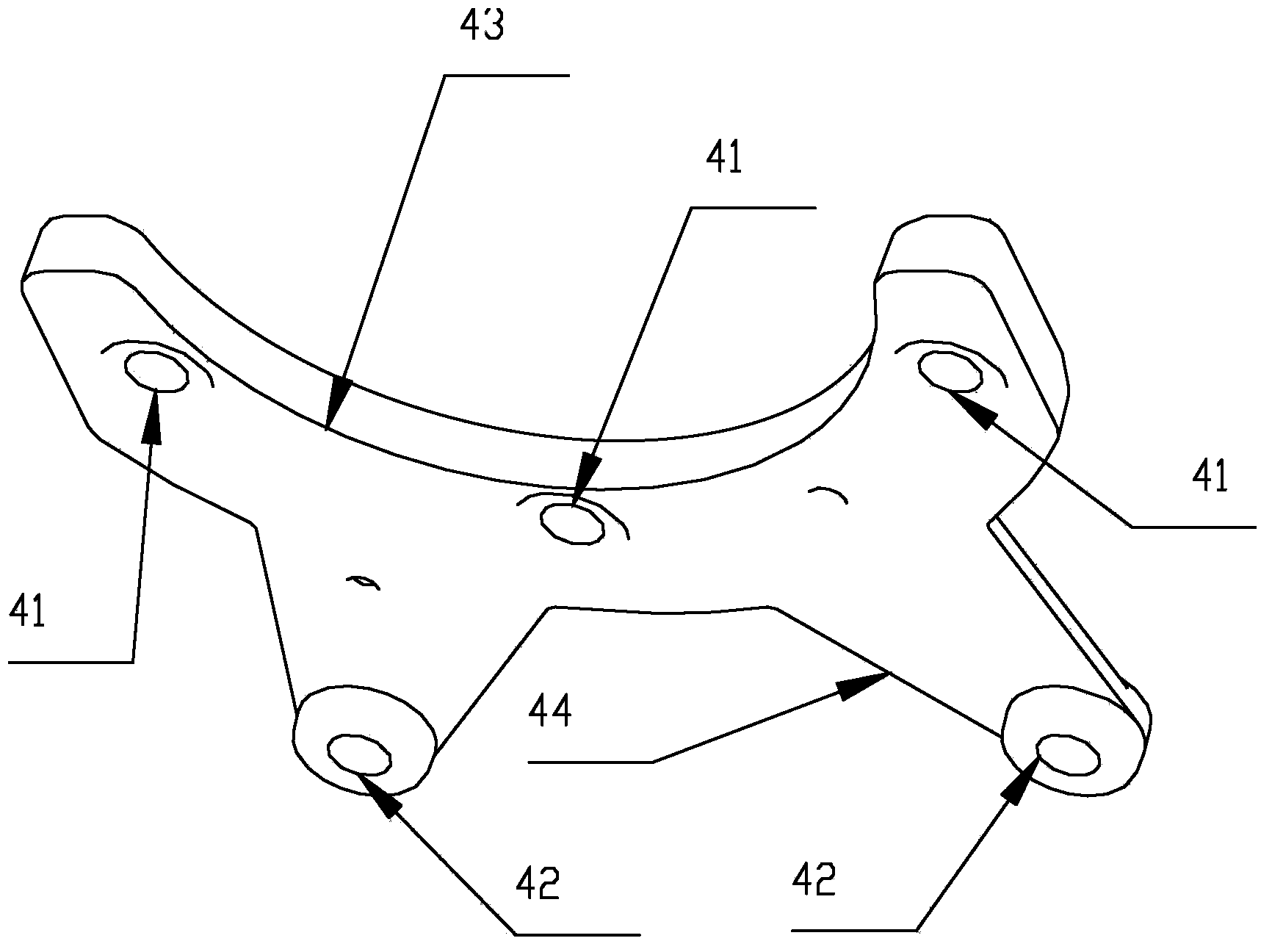

[0045] like Figure 1 to Figure 4 As shown, the two ends of the connector 4 described in this embodiment are respectively connected to the front ends of the first outer cylinder 2 and the second outer cylinder 3 . The upper end of the connecting piece 4 is arc-shaped at least partially matched with the lower contour of the front end of the first outer cylinder 2, the end is provided with a first upper connection hole 41 connected with the first outer cylinder 2, and the lower end is provided with a The connection part 44 , the end of the connection part 44 is provided with a first lower connection hole 42 connected with the second outer cylinder 3 .

[0046] The outer edge of the front end of the first outer cylinder 2 and the second outer cylinder 3 is provided with a mounting column 21, and the connecting piece 4 is installed on the mounting column through the first upper connection hole 41 and the first lower connection hole 42 respectively. 21, fasten with bolts 47 to con...

Embodiment 2

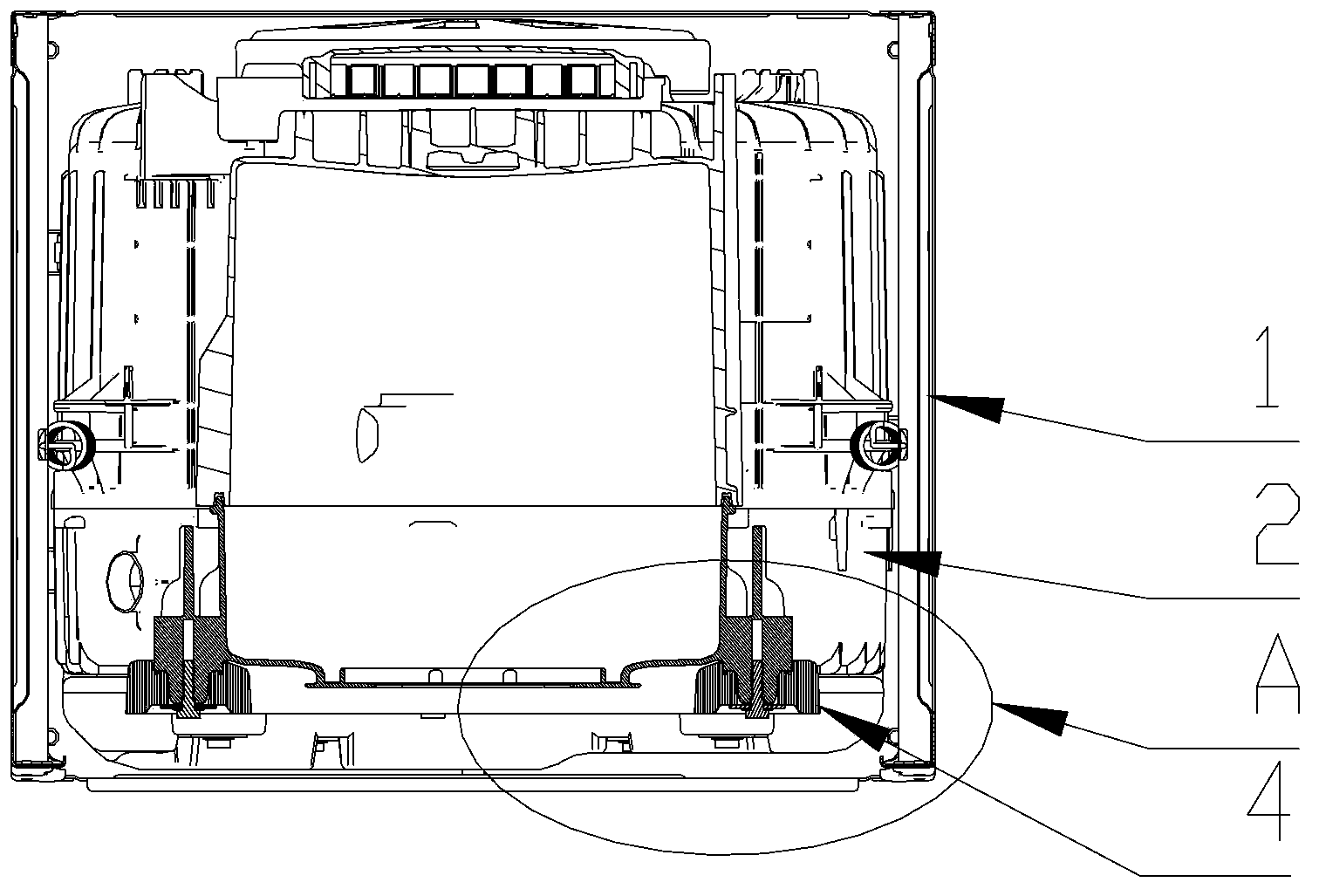

[0048] like Figure 5 and Image 6 As shown, the difference between this embodiment and the first embodiment is that the connecting piece 4 is integrally provided with the front end of the first outer cylinder 2 , and the end is connected with the front end of the second outer cylinder 3 .

[0049] The connecting piece 4 extends outwards from the lower front end of the first outer cylinder 2 , and its end is connected to the upper front end of the second outer cylinder 3 arranged at the lower part. Therefore, the second outer cylinder 3 is connected via the connecting piece 4 integrated with the first outer cylinder 2, so that the first outer cylinder and the second outer cylinder are integrated.

Embodiment 3

[0051] like Figure 1 to Figure 4 As shown, the connecting piece 4 described in this embodiment is a common counterweight of the first outer cylinder 2 and the second outer cylinder 3 , and neither the first outer cylinder 2 nor the second outer cylinder 3 is equipped with a counterweight structure. The connecting piece 4 is integrally provided with a counterweight 43, the upper end of the counterweight 43 is arc-shaped at least partially matched with the lower contour of the front end of the first outer cylinder 2, and the end is provided with a The first upper connecting hole 41 connected with the outer cylinder 2 has a connecting portion 44 at its lower end, and the end of the connecting portion 44 is provided with a first lower connecting hole 42 connected with the second outer cylinder 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com