Shirt fabric weaving process

A fabric and process technology, which is applied to the weaving process of weft triple weave shirt fabrics, can solve problems such as poor comfort, poor moisture absorption and perspiration, and inability to discharge in time, so as to maintain body feel, maintain shape retention and stiffness, The effect of improving moisture absorption and perspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

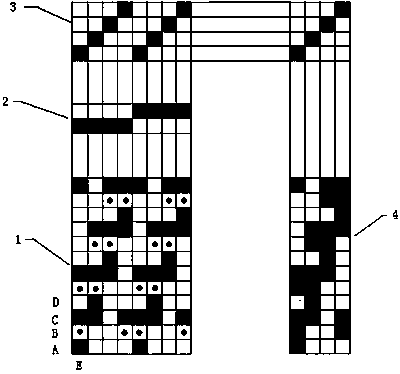

[0023] Fabric of the present invention adopts a kind of warp yarn JC / T (75 / 25) 40S; Four kinds of weft yarns, the polyester low-elastic network yarn of JC / T (75 / 25) 40S, 75D and JC / H (70 / 30) 40S and T75D18D conductive yarn, the fabric weave is triple weave.

[0024] The heald drawing method is: A1, A2, A3, A4 (the number represents the page on which the warp yarn is worn on the heald frame, and A yarn represents the warp yarn JC / T(75 / 25)40S).

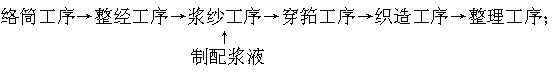

[0025] In the present invention figure 1 , figure 2 In the implementation shown, the process steps are: winding process→warping process→sizing solution preparation→sizing process→reeding process→weaving process→finishing process.

[0026] (1) Winding process:

[0027] The lining of the present invention is mainly composed of one kind of warp yarn, JC / T (75 / 25) 40S; there are four kinds of weft yarns, polyester low elastic network yarn of JC / T (75 / 25) 40S, 75D, JC / H (70 / 30 ) 40S and T75D18D conductive wire. German Schlafhorst AUTOC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com