Process for producing antistatic polyamide 6 (PA6) bulk yarns through one-step process

A production process and antistatic technology, applied in the direction of yarn, melt spinning, stretch spinning, etc., can solve whether the lodging resistance and wear resistance can meet the relevant national standards, elastic recovery performance, wear resistance decline, Increase environmental pollution and other issues in the production process, to avoid separation or highlighting of conductive fibers, excellent electrical conductivity, and improve the quality of carpet products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

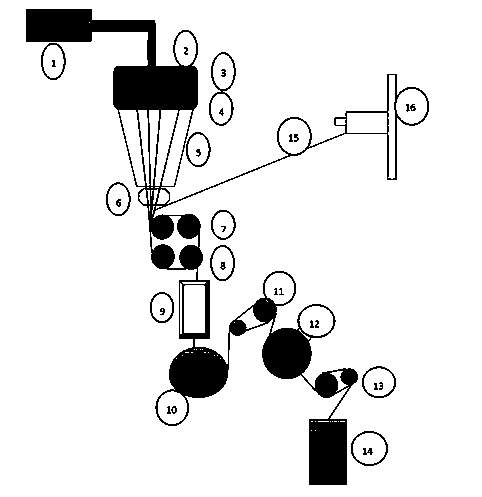

[0025] 1. Feed the dried nylon 6 chips uniformly into the screw extruder by metering and quantitatively, and extrude and melt them at a temperature of 260-290°C in the screw extruder to form a spinning melt. The spinning melt is in biphenyl It is fed into the metering pump installed in the spinning box under the temperature of 260-285 ℃, and the precisely metered melt through the metering pump is sent to the spinning assembly for high-pressure spinning;

[0026] 2. A monomer suction device is installed under the spinning assembly to remove the pyrolyzed monomers in the spinning process in time, so that the spinning area and spinneret are kept clean and free from pollution, so as to facilitate the production of spinning Ongoing;

[0027] 3. The melt forms high pressure in the spinning assembly and sprays continuous filaments through the spinneret, and is solidified into filaments after being cooled by side blowing in the side blowing tunnel. Side blowing is a kind of air-condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com