Method for extracting chitin from dried shrimp shells

A technology for chitin and shrimp shells, applied in the field of extraction of chitin and chitin polysaccharide, can solve the problems of low product purity, high transportation cost, high water and protein content, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A method for extracting chitin from dried shrimp shells,

[0042] (1) Coarse crushing: the dried shrimp shells are roughly crushed, and the obtained shrimp shell fragments have a diameter of 1 to 10 mm;

[0043] (2) Deep cleaning: soak 100kg of coarsely broken shrimp shells in water, add 1000kg of tap water or elutriation wastewater to soak, heat to 50°C, add 0.5kg of papain, stir for 5min, and keep the temperature at 50°C for reaction. Oscillate with an ultrasonic vibrator every 30 min, 3 min each time. After reacting for 6 hours, the solid-liquid mixture was poured into a 40-mesh sieve for filtration, and the turbid liquid and solid were collected respectively. The solid is washed with tap water to obtain clean shrimp shell fragments.

[0044] (3) Decalcification: Add 4wt% hydrochloric acid dropwise to the shrimp shell fragments, stop adding acid when the pH of the system drops to 4-5, and the solid obtained after solid-liquid separation is decalcified shrimp shell p...

Embodiment 2

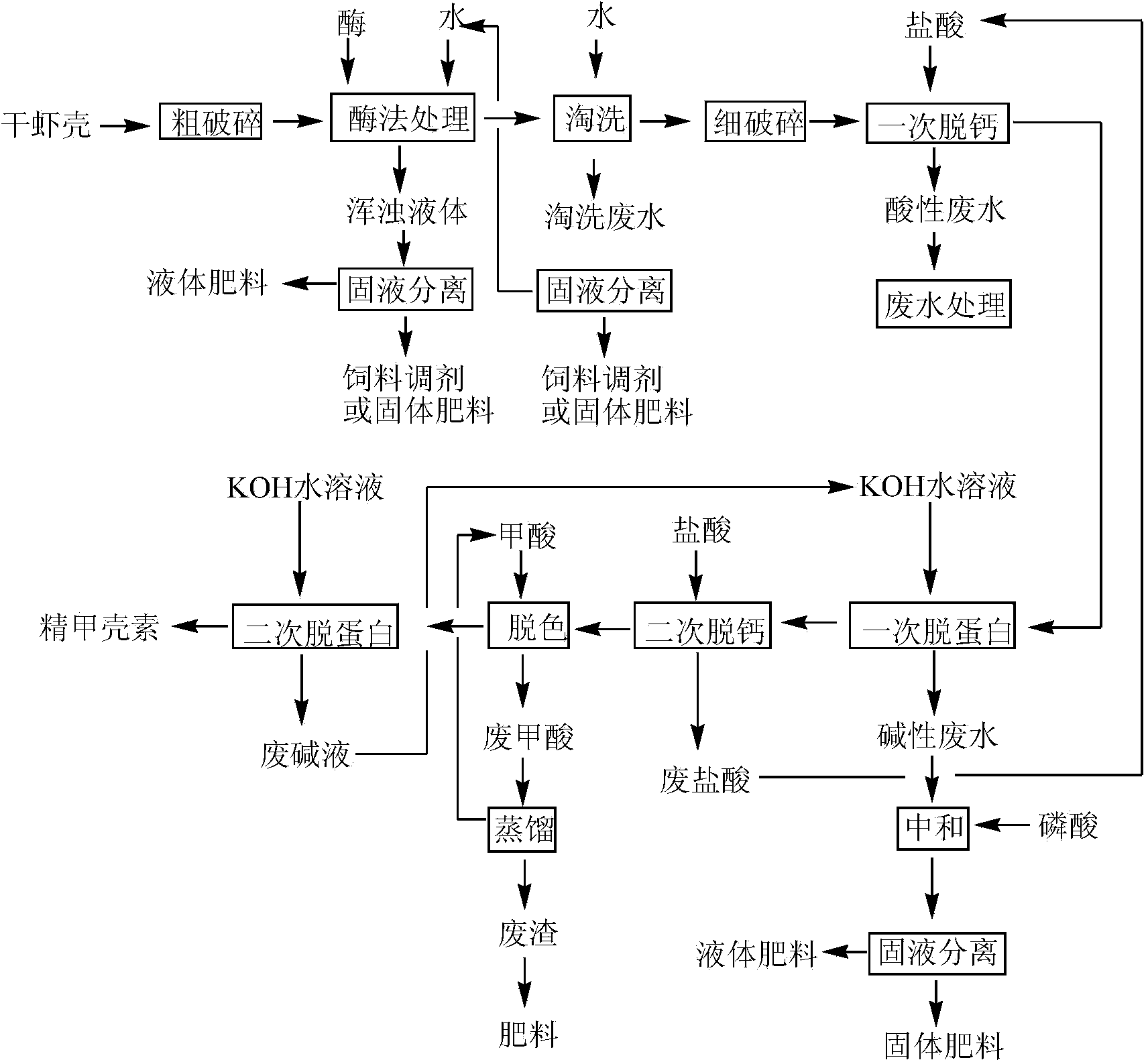

[0048] like figure 1 Shown, the preferred method of extracting chitin from dried shrimp shells, the steps are as follows:

[0049] (1) Coarse crushing: the dried shrimp shells are roughly crushed to obtain shrimp shell fragments with a diameter of 3-5 mm.

[0050] (2) Deep cleaning: Take 100kg of the above-mentioned shrimp shell fragments, add 1000kg of tap water or elutriation wastewater to soak, heat to 50°C, add 0.5kg of papain, stir for 5min, and keep the temperature at 50°C for reaction. Oscillate with an ultrasonic vibrator every 30 min, 3 min each time. After reacting for 6 hours, the solid-liquid mixture was poured into a 40-mesh sieve for filtration, and the turbid liquid and solid were collected respectively. The solid is washed with tap water to obtain clean shrimp shell fragments. After the above turbid liquid is left to settle, the supernatant is used to make liquid fertilizer, and the precipitate is used to make protein feed; flocculants can also be added to t...

Embodiment 3

[0058] The optimal method for extracting chitin from dried shrimp shells, the steps are as follows:

[0059] (1) Coarse crushing: coarsely crushing dried shrimp shells to obtain shrimp shell fragments with a diameter of 1-3 mm.

[0060] (2) Deep cleaning: Take 100kg of the above-mentioned shrimp shell fragments, add 900kg of tap water or elutriation wastewater to soak, heat to 40°C, add 1kg of neutral protease, stir for 5min, and keep the temperature at 40°C for reaction. Oscillate with an ultrasonic vibrator every 30 min, 3 min each time. After reacting for 8 hours, the solid-liquid mixture was poured into an 80-mesh sieve for filtration, and the turbid liquid and solid were collected respectively. The solid is washed with tap water to obtain clean shrimp shell fragments. After the above turbid liquid is left to settle, the supernatant is used to make liquid fertilizer, and the precipitate is used to make protein feed; flocculants can also be added to the turbid liquid, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com