Production method for preparing special fertilizer for red flower from tricalcium phosphate by-products

A technology of tricalcium phosphate and its production method, applied in the direction of chemical instruments and methods, applications, phosphorus compounds, etc., can solve problems affecting soil recycling, waste of nitrogen, phosphorus and potassium element resources, environmental pollution, etc., and achieve significant environmental protection value and economy Benefits, avoiding the discharge of waste liquid, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

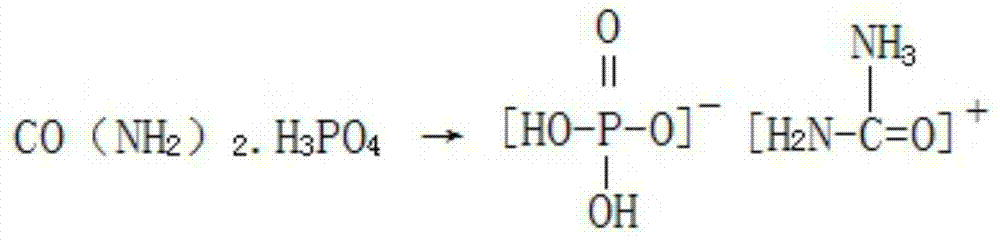

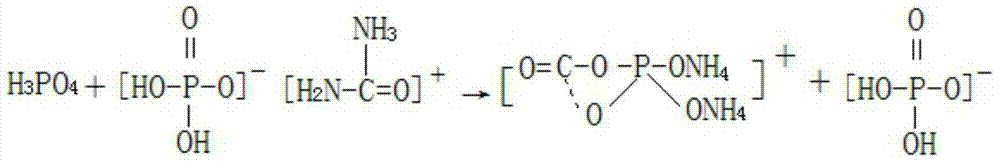

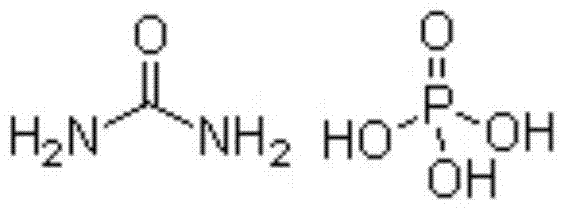

Embodiment 1

[0046] A production method for preparing tricalcium phosphate by-product safflower special fertilizer, using phosphoric acid to react with carbonamide to generate urea phosphate, and adjusting the temperature at 130°C, so that the structural formula of urea phosphate is ionized and separated to form dihydrogen phosphate ions and carbonamide positive ion, and then adopt carbonamide positive ion to approach phosphoric acid to form a structural formula of The intermediate ion body, and then add calcium ions to it, so that the calcium ions react with dihydrogen phosphate to generate tricalcium phosphate product slurry, and carry out cooling crystallization and centrifugal filtration treatment on the tricalcium phosphate product slurry, during the crystallization process , when the content of calcium nitrogen, phosphorus and calcium is detected to be 4:6:0.7, it is the end point of crystallization, and tricalcium phosphate filter cake and filtrate are obtained; the tricalcium phosp...

Embodiment 2

[0056] A production method for preparing tricalcium phosphate by-product safflower special fertilizer, using phosphoric acid to react with carbonamide to generate urea phosphate, and adjusting the temperature at 140°C to ionize and separate the structural formula of urea phosphate to form dihydrogen phosphate ions and carbonamide positive ion, and then adopt carbonamide positive ion to approach phosphoric acid to form a structural formula of The intermediate ion body, and then add calcium ions to it, so that the calcium ions react with dihydrogen phosphate to generate tricalcium phosphate product slurry, and carry out cooling crystallization and centrifugal filtration treatment on the tricalcium phosphate product slurry, during the crystallization process , when the content of calcium nitrogen, phosphorus and calcium is detected to be 6:4:0.5, it is the end point of crystallization, and tricalcium phosphate filter cake and filtrate are obtained; the tricalcium phosphate produc...

Embodiment 3

[0064] A production method for preparing tricalcium phosphate by-product safflower special fertilizer, using phosphoric acid to react with carbonamide to generate urea phosphate, and adjusting the temperature at 135°C to ionize and separate the structural formula of urea phosphate to form dihydrogen phosphate ions and carbonamide positive ion, and then adopt carbonamide positive ion to approach phosphoric acid to form a structural formula of The intermediate ion body, and then add calcium ions to it, so that the calcium ions react with dihydrogen phosphate to generate tricalcium phosphate product slurry, and carry out cooling crystallization and centrifugal filtration treatment on the tricalcium phosphate product slurry, during the crystallization process , when the content of calcium nitrogen, phosphorus and calcium in it is detected to be 5:5:0.6, it is the end point of crystallization, and tricalcium phosphate filter cake and filtrate are obtained; the tricalcium phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com