An AC Current Source for Exciting an Inductive Sensor

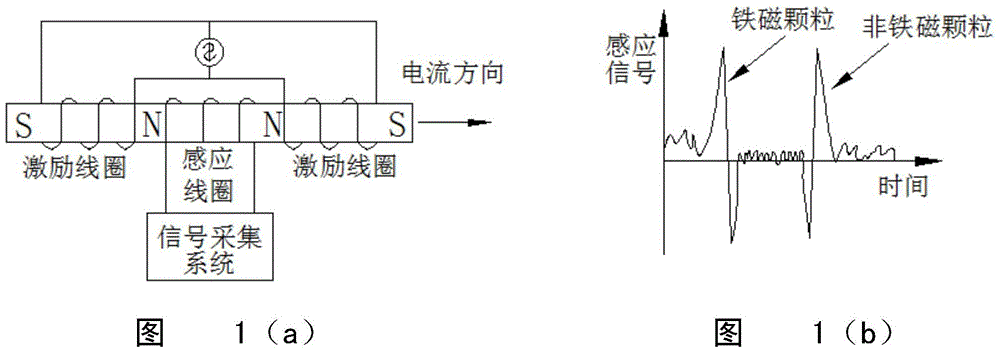

An AC current and sensor technology, applied in the direction of converting AC power input to AC power output, amplifiers, electrical components, etc., can solve the problems of being susceptible to electromagnetic interference, excitation coil excitation magnetic field changes, etc., to improve the degree of anti-interference, phase stability control, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

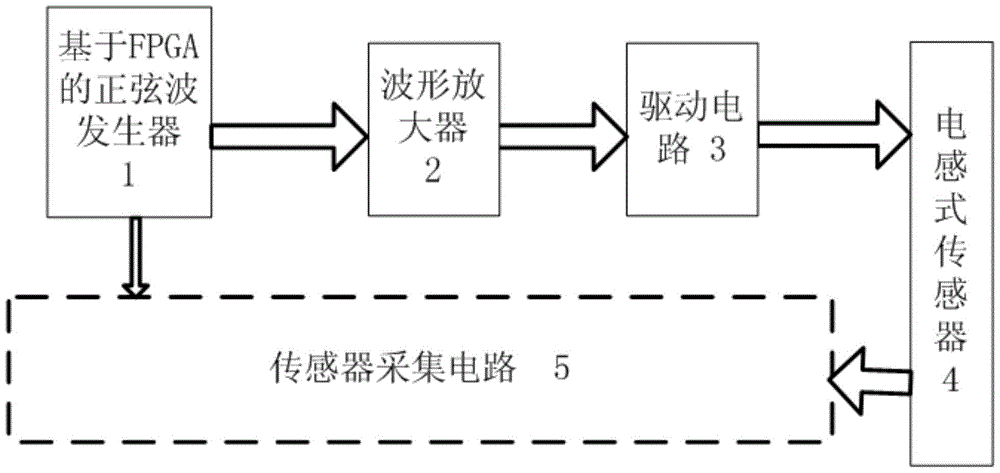

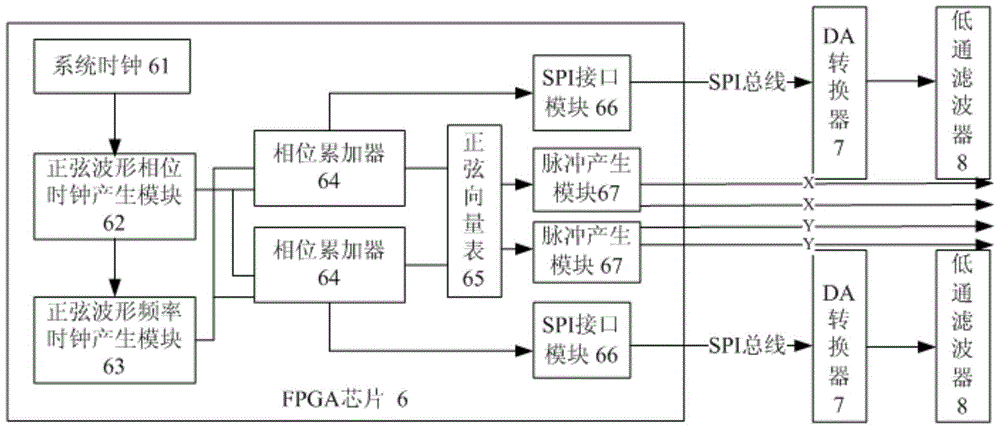

[0020] like figure 2 As shown, the present invention provides an AC current source for exciting an inductive sensor, which includes an FPGA-based sine wave generator 1 , a waveform amplifier 2 , a driving circuit 3 , an inductive sensor 4 and a sensor acquisition circuit 5 . The output terminal of the FPGA-based sine wave generator 1 outputs two sine wave signals and four pulse signals, the two sine wave signals are input into the waveform amplifier 2 for amplification, and the amplified sine wave signals are input into the drive circuit 3 for power amplification , the driving circuit 3 transmits an excitation signal to the inductive sensor 4 . The sensor acquisition circuit 5 is used to acquire the measurement signal of the inductive sensor 4 , and the four pulse signals output by the sine wave generator 1 are input to the sensor acquisition circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com