Rapid sub pixel edge detection and locating method based on machine vision

A sub-pixel edge, machine vision technology, used in instruments, image enhancement, image analysis, etc., can solve the problems of low detection and positioning accuracy, slow processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] The present invention will be further described in detail below in conjunction with the drawings and specific implementation process.

[0118] A fast sub-pixel edge detection and location method based on machine vision, comprising the following steps:

[0119] Step 1: Obtain the image of the PCB board to be inspected:

[0120] When the PCB board machine vision quality inspection and sorting system on the electronic manufacturing production line is running, the image of the PCB board to be inspected is obtained;

[0121] Step 2: Perform grayscale processing and denoising operations on the PCB board image to be detected to obtain a denoised image:

[0122] The adaptive median filtering method based on the template operation is used to remove the noise interference;

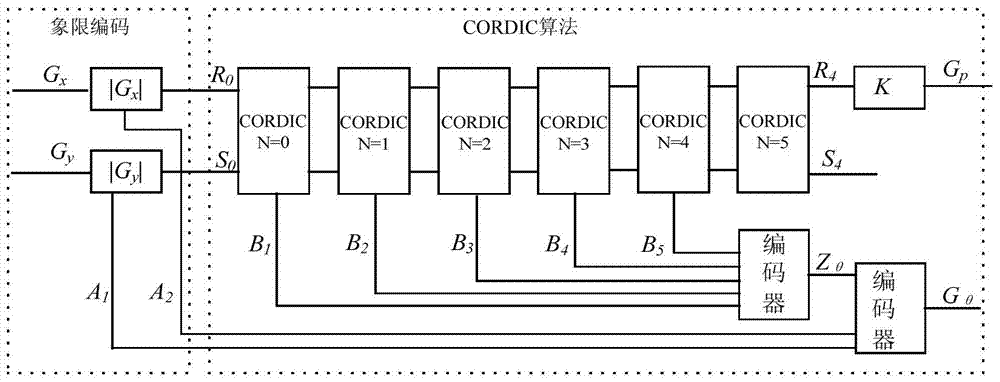

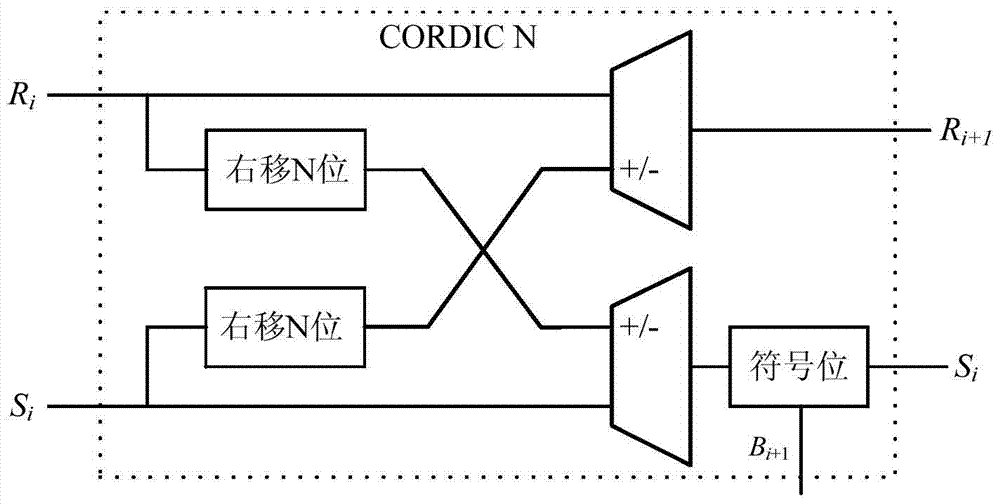

[0123] Step 3: Calculate the right-angle horizontal gradient G of each pixel in the horizontal direction on the denoised image x and a right-angled vertical gradient G in the vertical direction y ;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com