Metal rolling process automatic control hardware-in-loop simulation platform and method for experiment

A rolling process and simulation platform technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as difficulty in simulation and simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

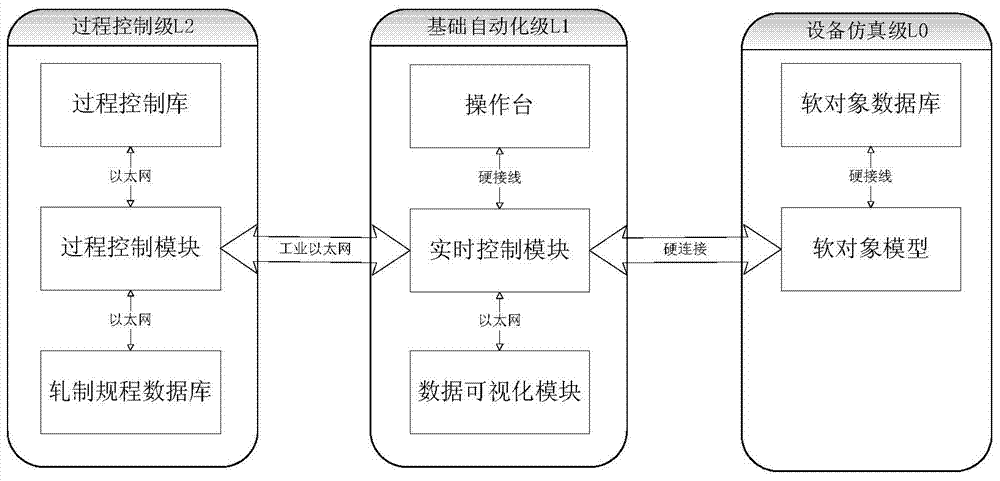

[0025] The metal rolling process automatic control hardware-in-the-loop simulation platform used in the experiment of this embodiment, such as figure 1 As shown, it includes: process control level L2, basic automation level L1 and equipment simulation level L0; the process control level L2 and the basic automation level L1 are connected to the field bus through Ethernet, and the basic automation level L1 is connected through a hardwire Connect to device emulation level L0.

[0026] The process control level L2 of this embodiment includes an engineer station, an operation terminal, a process optimization computer, a portable computer and a printer; the models of the main hardware used in this platform are shown in Table 1, wherein, the engineer station, the operation terminal and the process optimization computer All adopt the desktop compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com