A Corrosion Model Test Method for Tubular Turbine

A technology of tubular water turbine and model test, which is applied to the testing of machines/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

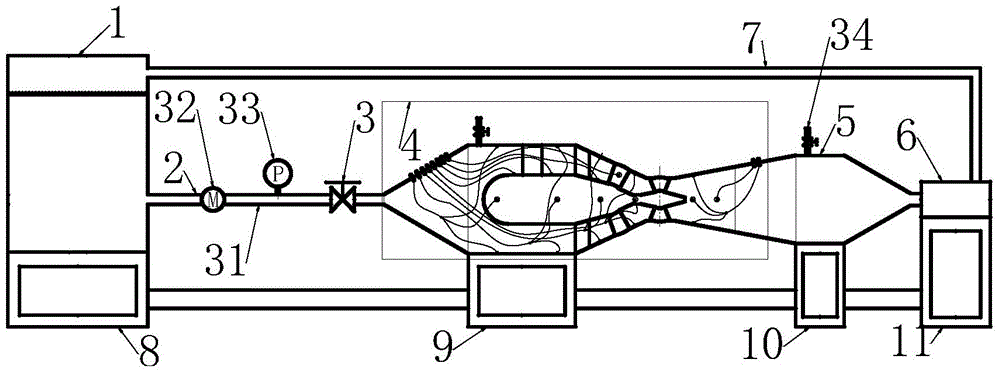

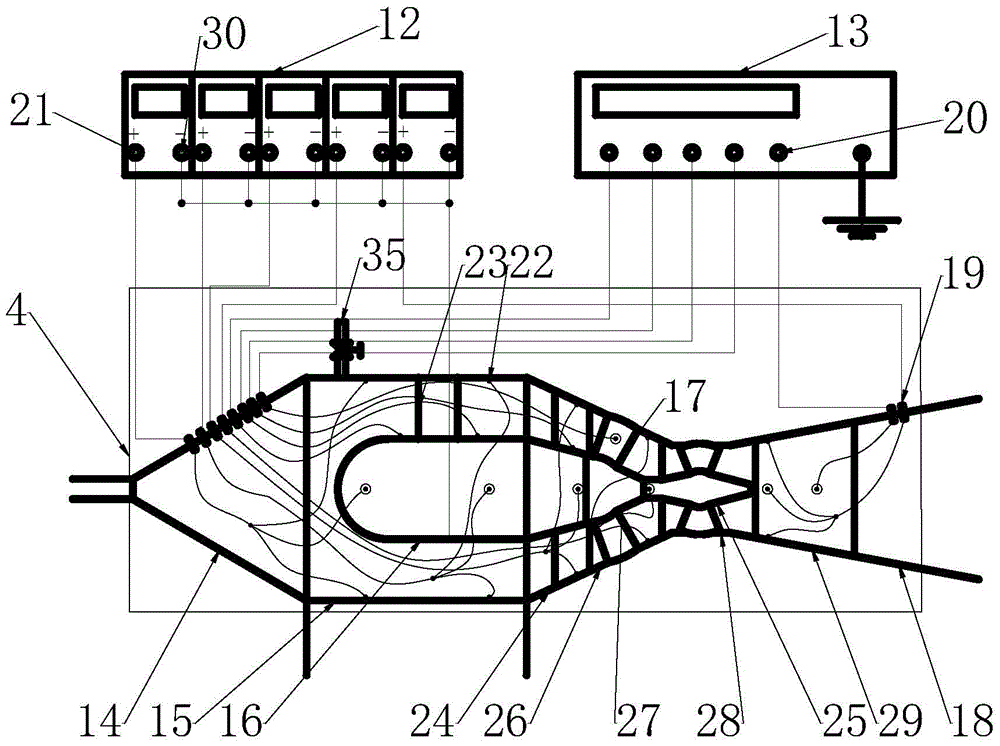

[0017] Such as figure 1 , figure 2 As shown, Step 1: According to the size of the real machine, according to the proportional relationship between the real machine and the model, increase the conductivity of the aqueous solution, prepare a diluted aqueous solution, and inject it into the water tank 1. Open the valve 3, so that the water in the water tank 1 is injected into the interior of the tubular turbine model 4 and the drainage box 5, and the drainage box 5 is connected with the tubular turbine model 4. Open the first exhaust valve 34 to discharge the air in the drainage tank 5, open the second exhaust valve 35 to discharge the air in the tubular turbine model 4, so that the aqueous solution is filled in the tubular turbine model 4 and the drainage tank 5 internal cavity.

[0018] Step 2: In the state of step 1, turn on the potentiostat 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com