High-voltage equipment temperature monitoring system based on ZigBee

A high-voltage equipment and monitoring system technology, applied in thermometers, thermometers using directly heat-sensitive electric/magnetic elements, signal transmission systems, etc., can solve the problem that the high-temperature alarm cannot be processed in time, and the monitoring center cannot know the high-temperature alarm event in real time and other issues to achieve low power consumption and ensure real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings.

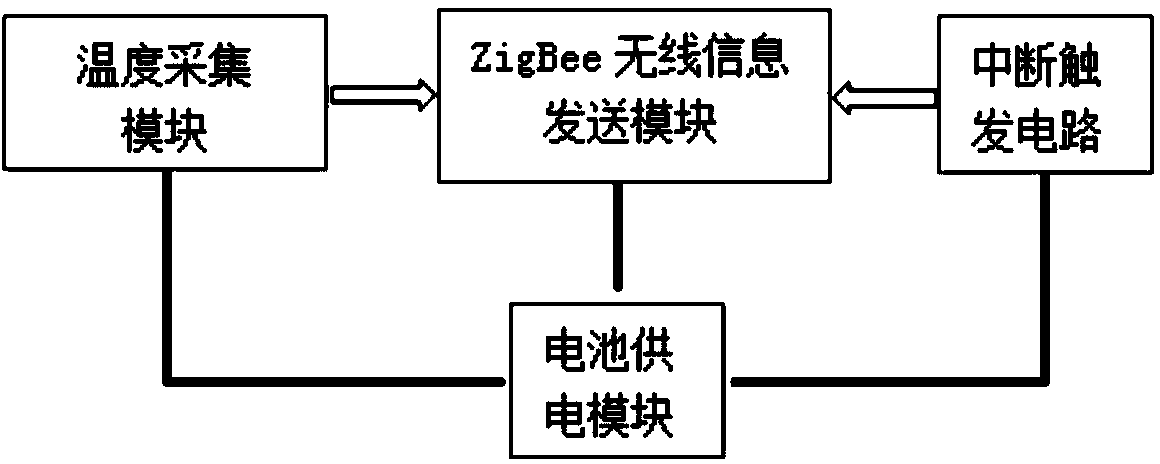

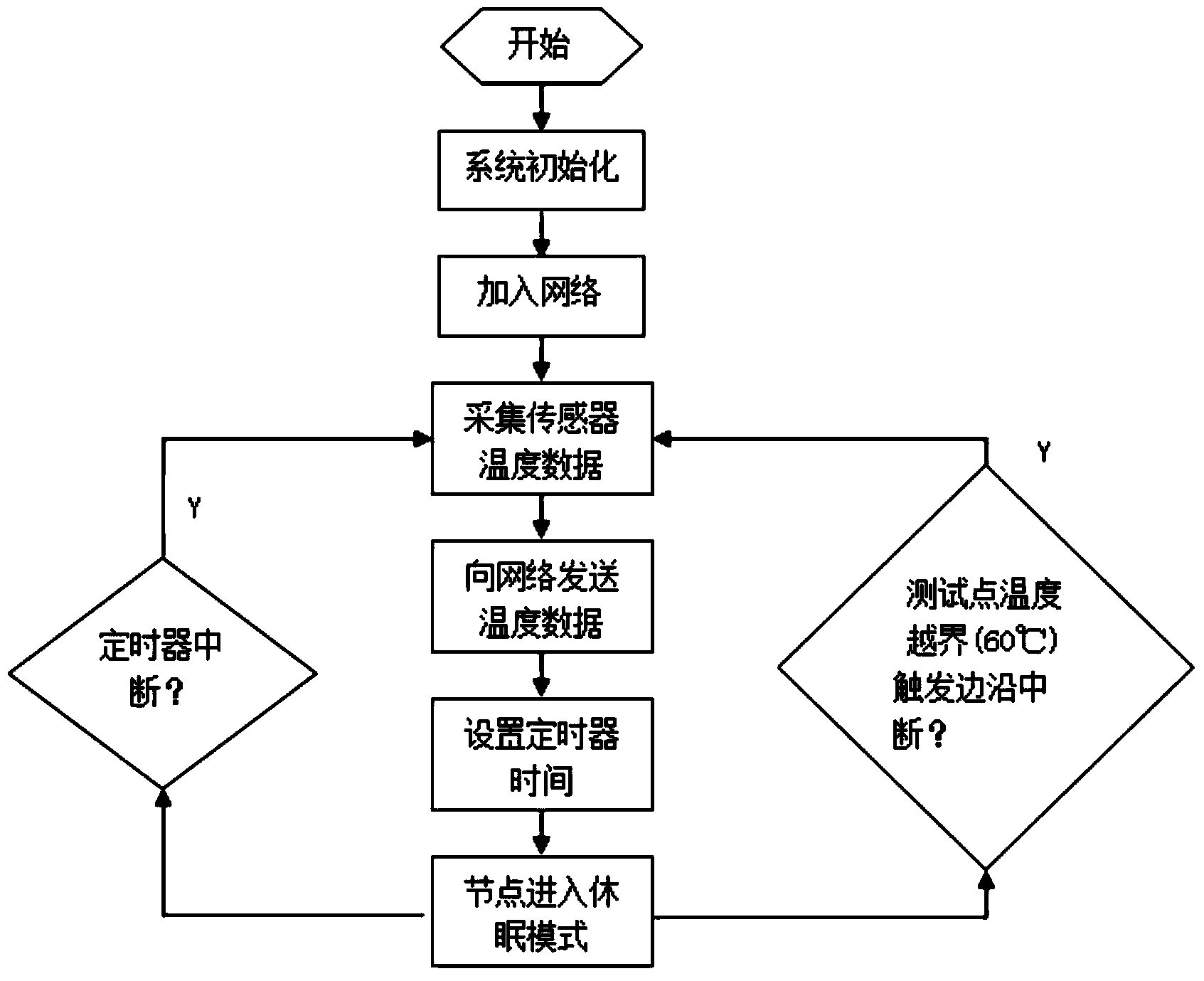

[0027] Such as figure 1 As shown, the ZigBee-based high-voltage equipment temperature monitoring system of the present invention includes a monitoring center 4, an RS485 bus 3, no less than one RS485 gateway 1 and several ZigBee terminal nodes corresponding to each RS485 gateway 1. A ZigBee terminal node and a corresponding ZigBee coordinator form a star-shaped ZigBee network through a wireless connection. The RS485 gateway 1 includes a ZigBee coordinator and an RS485 forwarding module; the ZigBee terminal node is used to collect temperature data from high-voltage equipment monitoring points, RS485 Gateway 1 is used to forward data to the monitoring center through the RS485 bus.

[0028] figure 1 The ZigBee coordinator and several corresponding ZigBee terminal nodes form the ZigBee wireless network transmission module 2. Several ZigBee terminal nodes collect the temperature of the monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com