Forklift balancing weight detecting device and detecting method

A detection device and counterweight technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of cumbersome operation, high energy consumption, low accuracy, etc., to ensure aesthetics, uniform gap, open file Qualified size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

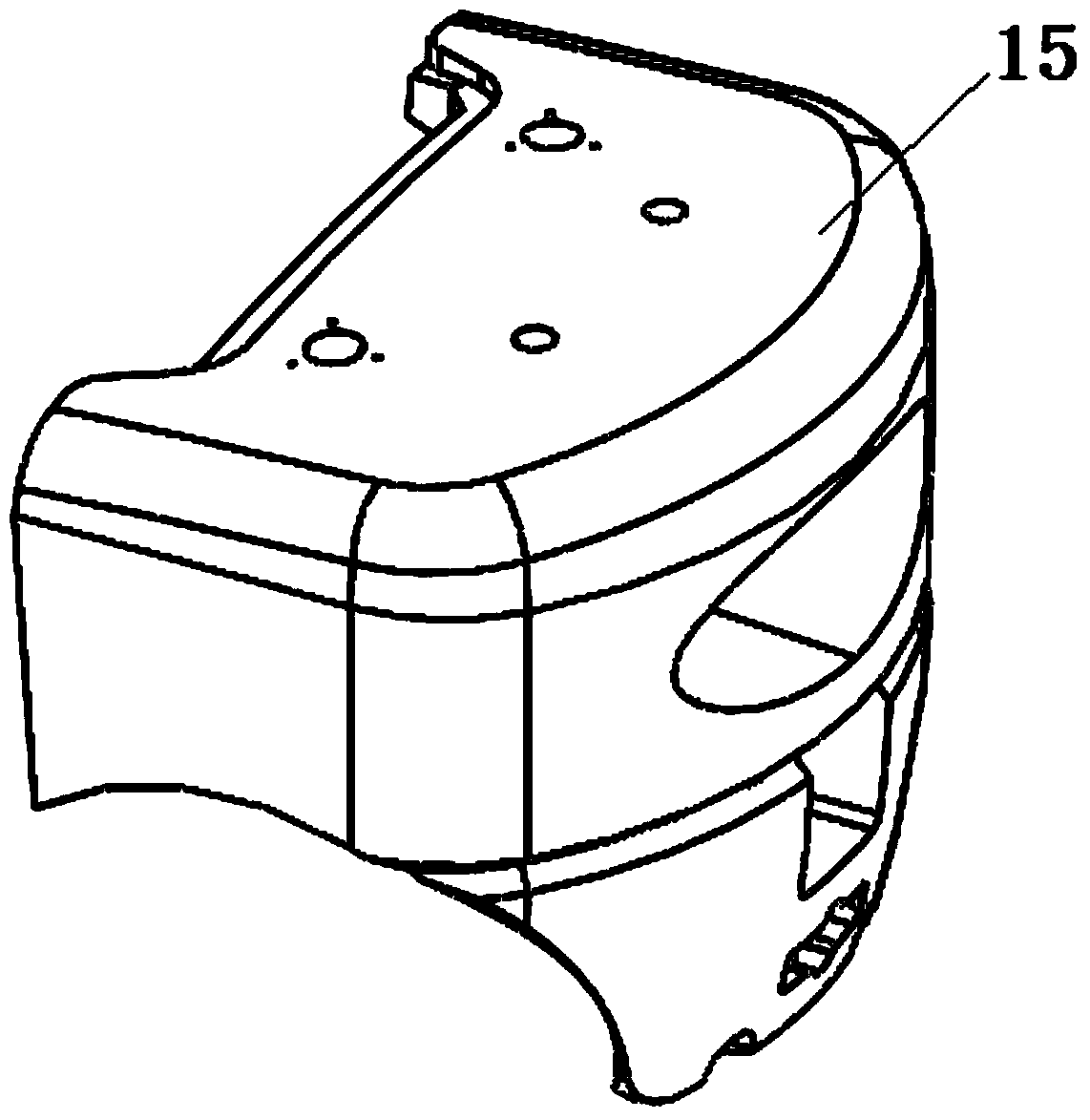

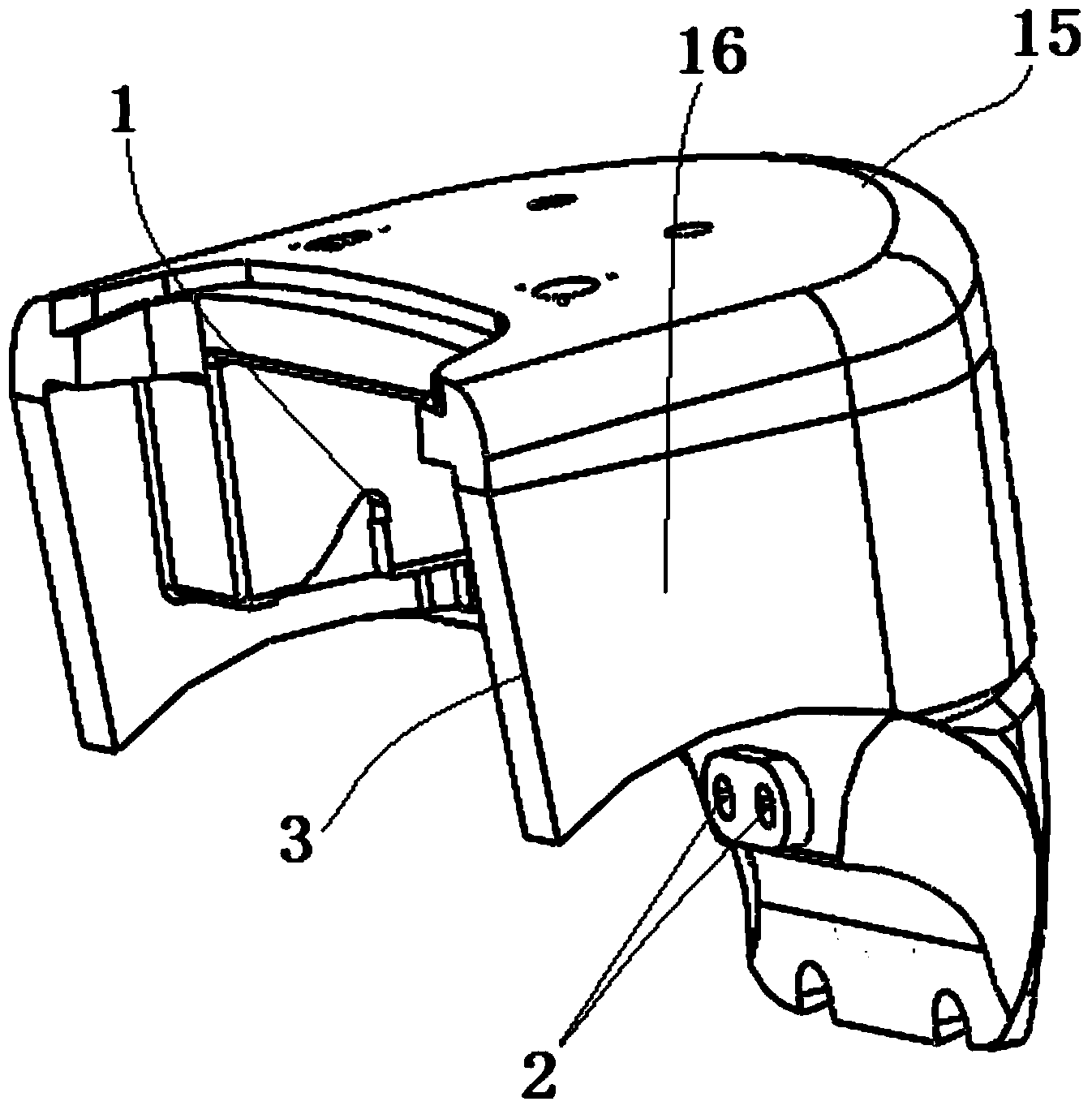

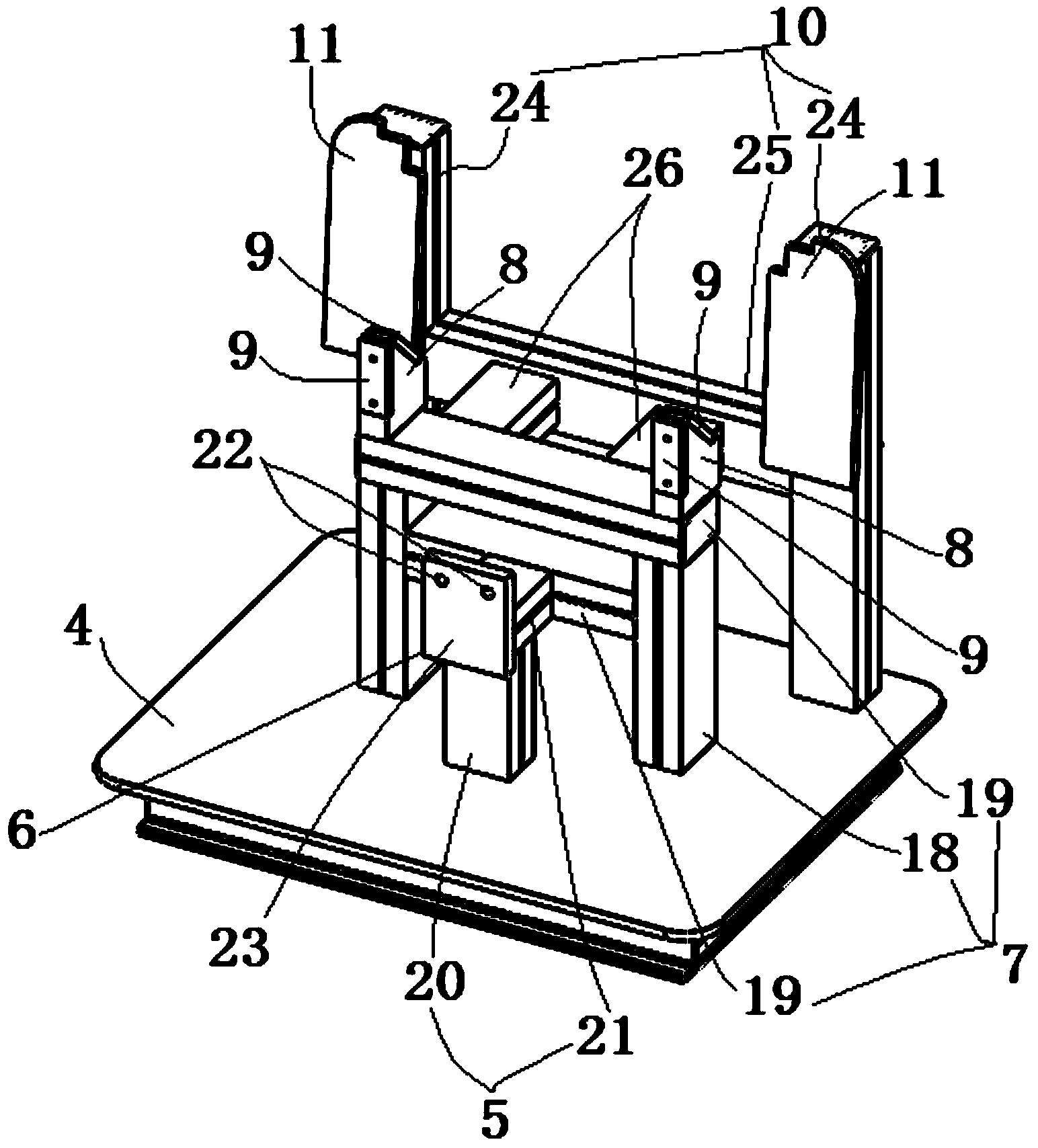

[0051] Embodiment 1, the forklift balance weight detection method is realized by using the forklift balance weight detection device, the balance weight 15 is placed on the detection device, the positioning support block 8 is supported on the balance weight hanging groove 1, and the detection block 6 is installed with the balance weight The position of the hole 2 is close, and the specific detection surface 23 is close to the inner surface of the balance weight installation hole 2, so as to realize the positioning support of the balance weight 15;

[0052] If the balance weight installation hole 2 coincides with the detection hole 22 on the detection block 6, then the balance weight 15 is qualified; qualified.

Embodiment 2

[0053] Embodiment 2, the forklift balance weight detection method is realized by using the forklift balance weight detection device, the balance weight 15 is placed on the detection device, the positioning support block 8 is supported on the balance weight hanging groove 1, and the detection block 6 is installed with the balance weight The position of the hole 2 is close, and the specific detection surface 23 is close to the inner surface of the balance weight installation hole 2, so as to realize the positioning support of the balance weight 15;

[0054] If the side line 3 of the balance weight is parallel to the corresponding detection line 12 on the detection inclined plate 11, and the distance between the two is within the set range, then the balance weight 15 is qualified; if the side line 3 of the balance weight is parallel to the detection inclined plate 11 If the corresponding detection edge 12 on the top is not parallel, or the distance between the balance weight side ...

Embodiment 3

[0055] Embodiment 3, the forklift balance weight detection method is realized by using the forklift balance weight detection device, the balance weight 15 is placed on the detection device, the positioning support block 8 is supported on the balance weight hanging groove 1, and the detection block 6 is installed with the balance weight The position of the hole 2 is close, and the specific detection surface 23 is close to the inner surface of the balance weight installation hole 2, so as to realize the positioning support of the balance weight 15;

[0056] If the counterweight side 16 and the corresponding detection side 17 on the detection swash plate 11 are on the same plane, then the balance weight 15 is qualified; if the counterweight side 16 and the corresponding detection side 17 on the detection swash plate 11 are not on the same plane, Then the balance weight 15 is unqualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com