Water turbine with water pumping function

A water turbine and functional technology, applied in the direction of pumps, pump devices, mechanical equipment, etc., can solve the problems of high production cost, high cost, dependence, etc., and achieve the effect of good sealing performance and small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

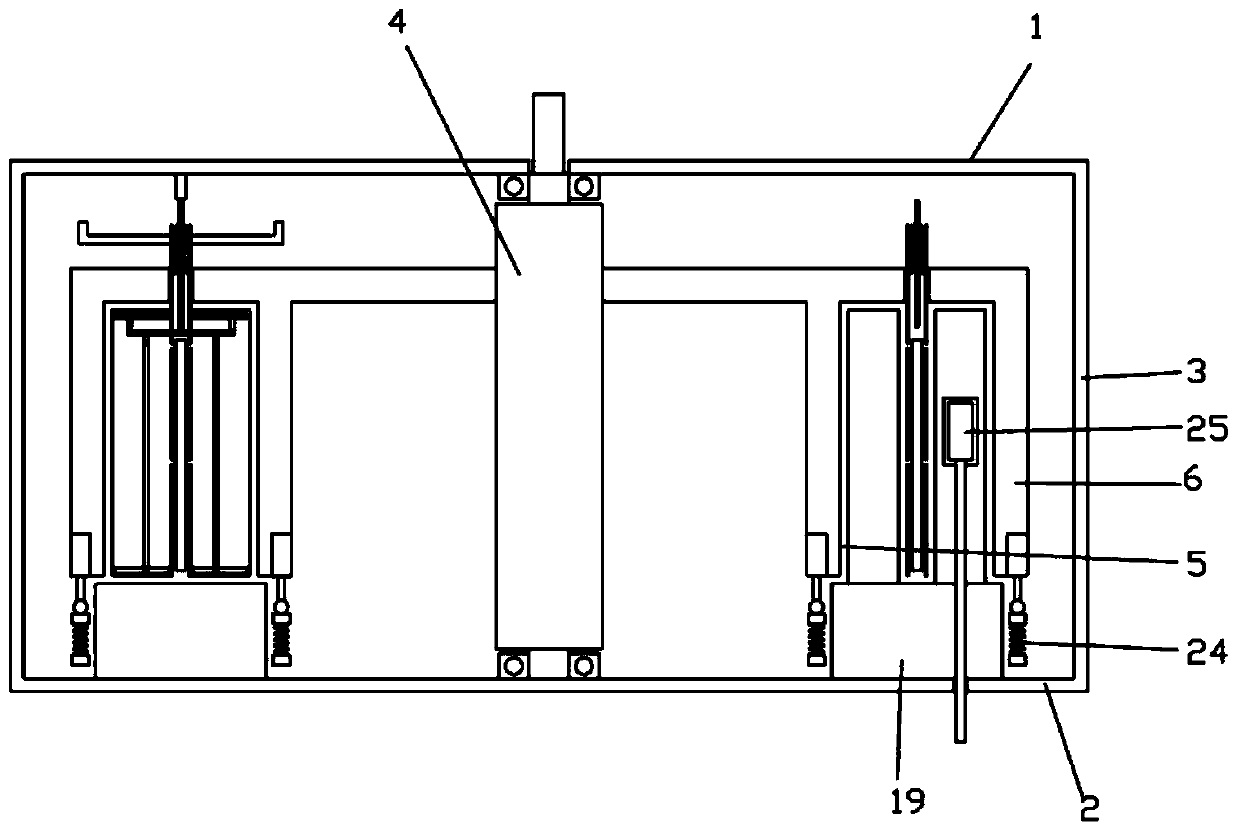

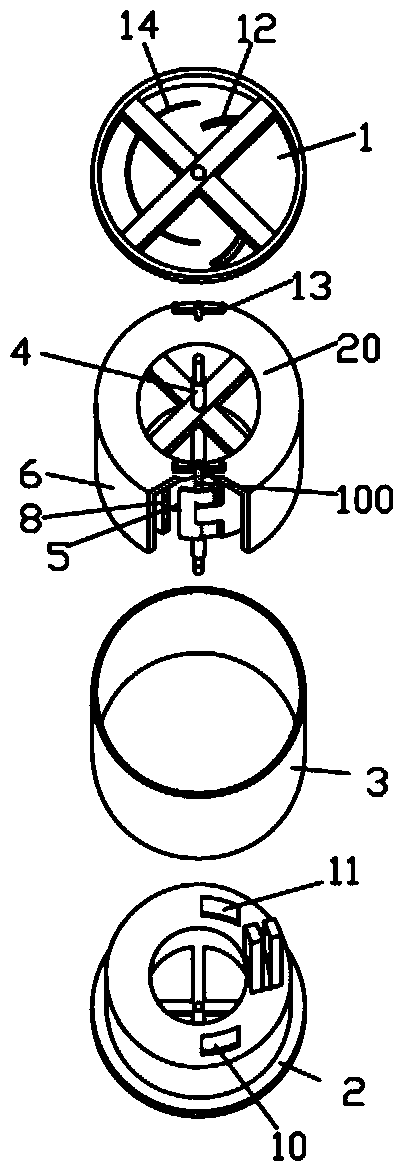

[0042] Such as Figure 1-Figure 7 As shown, a water turbine with the function of pumping water includes a shell composed of an upper end cover 1, a lower end cover 2 and a side wall 3, and a rotatable water wheel shaft 4 is installed between the upper end cover 1 and the lower end cover 2. A rotor is installed on the water wheel shaft 4, and the lower end cover 2 is provided with a water inlet 10 and a water outlet 11 in the opposite direction centered on the water wheel shaft 4.

[0043]The rotor is sequentially provided with an outer cylinder 6, a blade cylinder 8 and an inner cylinder 5 coaxial with each other from the outside to the inside, an outer ring is formed between the outer cylinder 6 and the blade cylinder 8, and the blade cylinder 8 An inner ring is formed between the inner cylinder and the inner cylinder 5. The axial cross-sectional areas of the outer ring and the inner ring are not equal. The side communicates with the water outlet 11; the outer cylinder 6, th...

Embodiment 2

[0055] see Figure 7-Figure 9 The difference between this embodiment and Embodiment 1 of the hydraulic turbine with pumping function shown is that there is no outer cylinder on the rotor of the hydraulic turbine with pumping function described in this example, but the outer cylinder is replaced by side wall 3 function.

[0056] Specifically, see Figure 8-Figure 9 , the water turbine with the function of pumping water described in this embodiment includes a housing composed of an upper end cover 1, a lower end cover 2 and a side wall 3, and a rotatable water pump is installed between the upper end cover 1 and the lower end cover 2. The wheel shaft 4, the rotor is installed on the water wheel shaft 4, the side wall 3 is provided with a water inlet 10' and a water outlet 11' in the opposite direction centered on the water wheel shaft 4, and the rotors are arranged in sequence from outside to inside There are mutually coaxial blade cylinders 8 and inner cylinders 5, an outer ri...

Embodiment 3

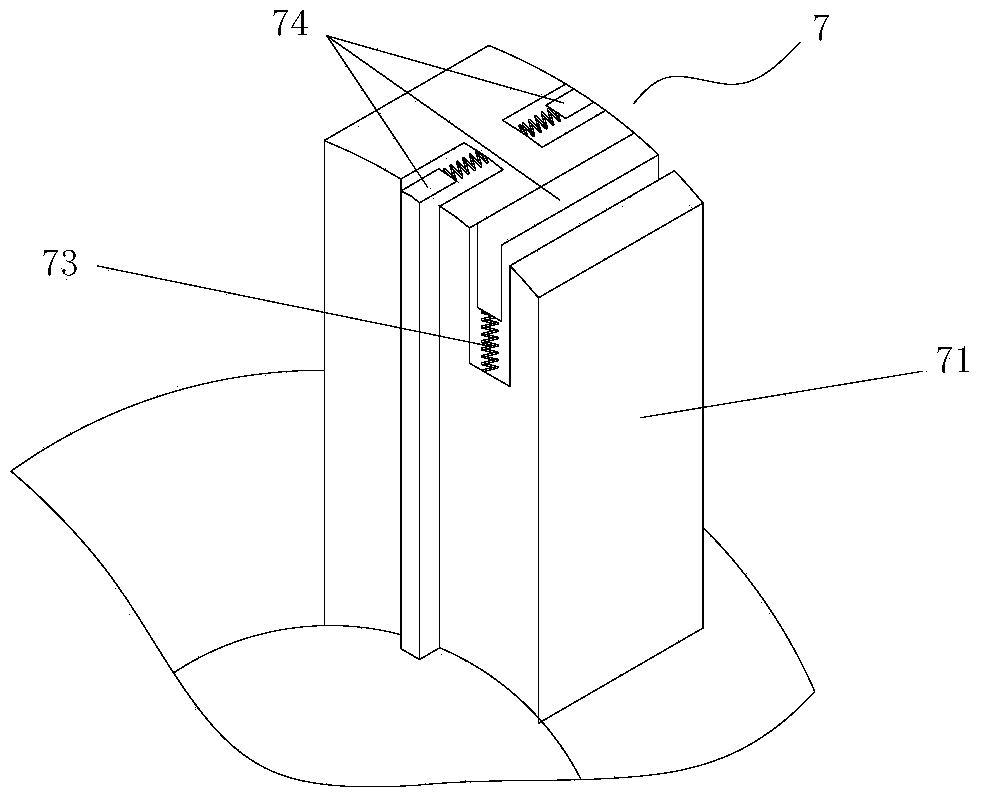

[0063] see Figure 11 , this embodiment shows the application of the coaxial connection of the hydraulic turbine with pumping function in embodiment 1 or embodiment 2. The hydraulic turbine with pumping function of the present invention works as a water pump with the The direction of rotation is reversed. In this embodiment, the upper water turbine that also has the function of pumping water is used as a water turbine for output power, and the lower water turbine is used as a water pump. When the device is placed in the water flow, the power output from the upper water turbine is transmitted to the lower water pump through the water wheel shaft 4 to drive the rotor to rotate, thereby completing the function of pumping water. Can make the scope of application wider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com