Method and device for extracting erythromycin thiocyanate

A technology of erythromycin thiocyanate and an extraction method, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of low product purity and low product yield, and achieve high purity, high high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

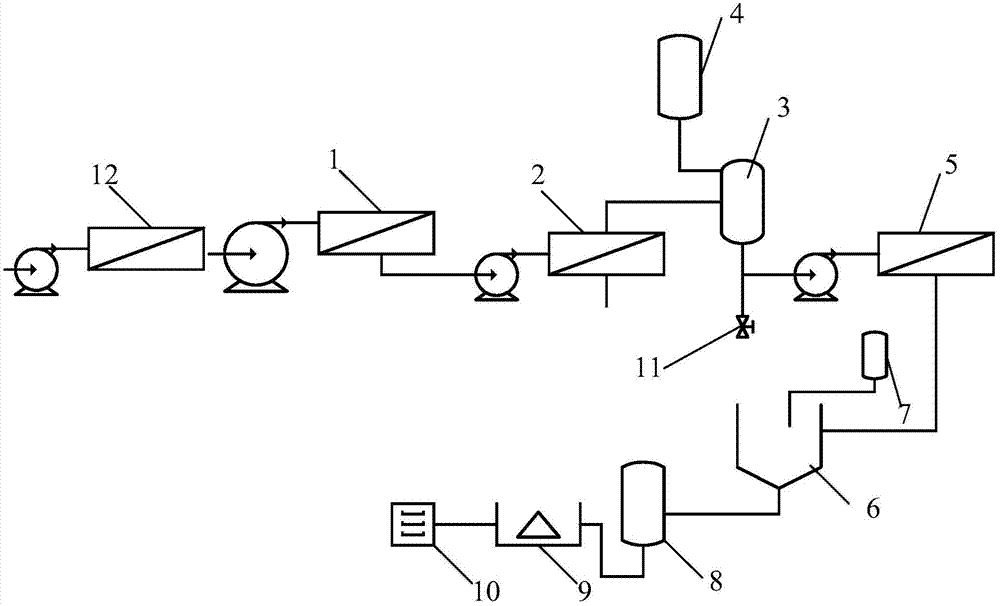

Image

Examples

Embodiment 1

[0052]Take 100L of erythromycin fermentation broth and heat it up to 65°C, and then filter it through a titanium oxide ceramic ultrafiltration membrane. Send the ultrafiltration permeate to the nanofiltration membrane for concentration. The material of the nanofiltration membrane is sulfonated polysulfone, the molecular weight cut-off is 200Da, the nanofiltration temperature is 50°C, and the pressure is 1.4MPa. Concentrate and concentrate 8 times to obtain a concentrated solution , then add the acetone of concentrated solution volume 1 / 4 wherein, carry out extraction, separate the organic phase, flow the sodium thiocyanate solution of 20wt.% in the organic phase (add 0.4 mole of thiocyanate in every 1 mole of erythromycin thiocyanate), and then adjust the pH to about 7.5 with 50% glacial acetic acid solvent, add purified water according to 1 times the volume of the organic phase, control the crystallization temperature at 25-30°C, stir slowly for 10 minutes, let stand for 4 hou...

Embodiment 2

[0054] Take 100L of erythromycin fermentation broth and heat it up to 65°C, filter it with an alumina microfiltration membrane, the average pore size of the microfiltration membrane is 200nm, and filter the microfiltration permeate through a titanium oxide ceramic ultrafiltration membrane, the average pore size of the ultrafiltration membrane is The transmembrane pressure is 20nm, the transmembrane pressure difference is 0.2MPa, and the membrane surface flow rate is 2m / s. After being concentrated 8 times, the ultrafiltration permeate is sent to the nanofiltration membrane for concentration. The material of the nanofiltration membrane is sulfonated polysulfone, and the molecular weight cut off 200Da, nanofiltration temperature 50°C, pressure 1.4MPa, concentrate, concentrate 8 times to obtain a concentrated solution, then add acetone with 1 / 4 of the concentrated solution volume to it for extraction, separate the organic phase, and add 20wt to the organic phase .% sodium thiocyana...

Embodiment 3

[0056] Take 100L of erythromycin fermentation broth and heat it up to 55°C, and filter it through a titanium oxide ceramic ultrafiltration membrane. The ultrafiltration permeate is sent to the nanofiltration membrane for concentration. The material of the nanofiltration membrane is polyamide, sulfonated polysulfone, polyacrylonitrile, sulfonated polyethersulfone and polyimide, and the molecular weight cut-off is 200Da. Concentrate at a temperature of 40°C and a pressure of 2.0MPa, and concentrate 8 times to obtain a concentrated solution, then add acetone with 1 / 4 of the concentrated solution volume to it for extraction, separate the organic phase, and add 20wt.% sulfur to the organic phase Sodium cyanate solution (add 0.4 moles of sodium thiocyanate to 1 mole of erythromycin), adjust the pH to about 7.5 with 50% glacial acetic acid solvent, add purified water by 1 times the volume of the organic phase, and control the crystallization temperature at 25 Stir slowly at ~30°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com