Method for preparing dihydric alcohol mono-t-butyl ether

A technology of mono-tert-butyl ether and diol, which is applied in the field of chemical preparation process, can solve the problem of low selectivity and achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

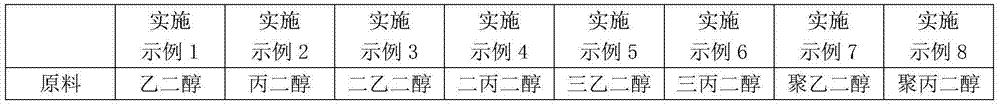

[0022] In the above method, the dihydric alcohol is at least one of ethylene glycol, propylene glycol, diethylene glycol, dipropylene glycol, triethylene glycol, tripropylene glycol, hexylene glycol, and octapentyl glycol.

[0023] The feature of this patent is that, compared with raw materials and corresponding products, it is more important for dihydric alcohols to be able to react with carbon four, so several dibasic alcohols provided in this example are obtained by the applicant in combination with a large number of repeated experiments. The products suitable for the patented process are screened out, and all can well participate in the reaction in the process.

Embodiment 2

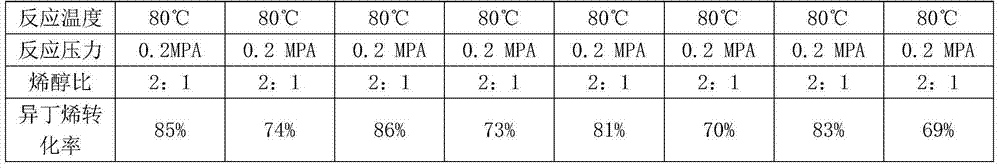

[0025] In the above method, the liquefied petroleum gas includes a hydrocarbon mixture with an atomic number of 4; the hydrocarbon mixture includes isobutene with a content of 20%-99%.

[0026] In this embodiment, if the isobutene content in the C4 hydrocarbon mixture is less than 20%, the yield of the diol mono-tert-butyl ether compound decreases, and the reaction efficiency may decrease. Therefore, when selecting the C4 hydrocarbon mixture, it should be greater than 20%, preferably more than 30%.

Embodiment 3

[0028] In the above method, the hydrocarbon mixture further includes dihydric alcohol; the molar ratio of dihydric alcohol to isobutylene is 1:1-4:1.

[0029] Through repeated experiments, it has been found that if the molar ratio of isobutylene and diol compound is less than 1:1, the efficiency of the catalytic reaction will be too low, and when it is greater than 4:1, the unreacted diol will increase, and the cost of the recycling reaction will be increased. The increase in investment will increase the cost more. Therefore, this embodiment proposes a molar ratio of diol to isobutylene that better balances the above-mentioned advantages and disadvantages after a lot of creative work, that is, 1:1-4:1. Further, 1.5:1-2.5:1 can be optimally selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com