Preparation method of light calcium carbonate

A light calcium carbonate and limestone technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of low quality and many filler impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

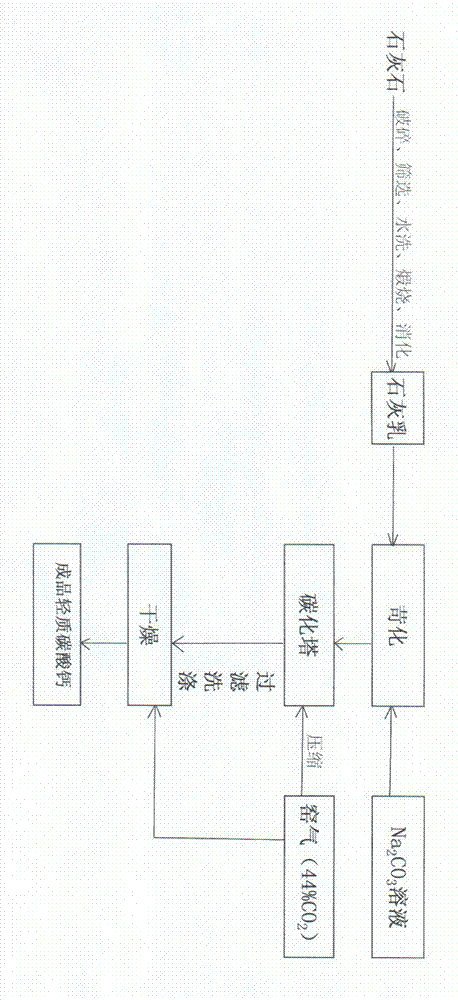

Image

Examples

Embodiment Construction

[0015] A kind of preparation method of light calcium carbonate, it comprises the steps:

[0016] (1) Crushing: Put the limestone raw material into the crusher for crushing;

[0017] (2) Screening and washing: place the crushed limestone in a sieve with a pore size of 5 cm for screening, and wash the screened limestone with water at the same time;

[0018] (3) Calcination: place the screened and washed limestone in a vertical kiln for calcination, the calcination temperature is 900-1300°C, and the calcination time is 3-5 hours to produce quicklime (CaO) and carbon dioxide (CO2);

[0019] (4) Digestion: add quicklime generated by calcining limestone into hot water, the ratio of quicklime to hot water is 1:6, and the temperature of hot water is 90°C, stirring continuously to generate milk of lime;

[0020] (5) Pass the generated milk of lime through a 120-mesh sieve, and then filter the milk of lime to an effective CaO concentration of >170g / L;

[0021] (6) Causticizing: move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com