Production method for preparing monopotassium phosphate and byproduct special fertilizer for medlar

A technology of potassium dihydrogen phosphate and production method, applied in chemical instruments and methods, applications, phosphorus compounds, etc., can solve problems such as environmental pollution, lack of pertinence, waste of resources, etc., to avoid environmental pollution, reduce production costs, and avoid The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

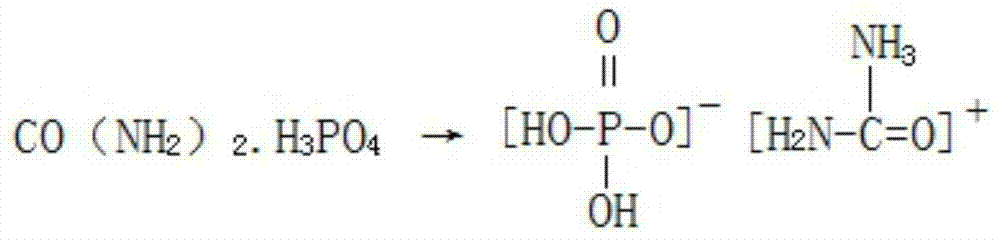

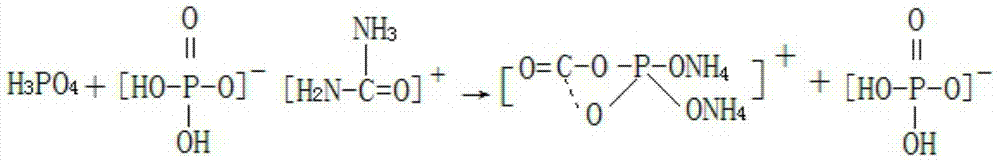

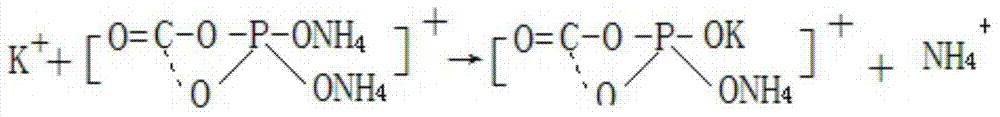

Method used

Image

Examples

Embodiment 1

[0047] A production method for preparing potassium dihydrogen phosphate by-product wolfberry special fertilizer, comprising the following steps:

[0048] (1) Preparation and mixing of raw materials: Put phosphoric acid and carbonamide in a stirred reactor at a molar ratio of 2.3:1, raise the temperature to 110°C at a heating rate of 11°C / min, and control the stirring speed of the stirring tank to 130r / min to stir Mixing reaction 3h, obtain intermediate slurry;

[0049] (2) Preparation of KH 2 PO 4 : Add alkaline potassium salt again and contain step 1) in the reaction kettle of the intermediate slurry that makes, the addition is 3 times of the amount of carboxamide, and employing stirring speed is that 100r / min stirring reaction 55min, obtains phosphoric acid di Slurry of potassium hydrogen;

[0050] (3) Cyclic crystallization and filtration: place the slurry obtained in step 2) in a cooling crystallizer to cool down to a temperature of 15°C, cool down to cyclic crystalliza...

Embodiment 2

[0055] A production method for preparing potassium dihydrogen phosphate by-product wolfberry special fertilizer, comprising the following steps:

[0056] (1) Preparation and mixing of raw materials: put phosphoric acid and carbonamide in a stirred reactor at a molar ratio of 2.5:1, raise the temperature to 130°C at a heating rate of 11°C / min, and control the stirring speed of the stirring tank to 110r / min to stir Mixing reaction 3h, obtain intermediate slurry;

[0057] (2) Preparation of KH 2 PO 4 : Add alkaline potassium salt again and contain step 1) in the reaction kettle of the intermediate slurry that makes, the addition is 3 times of the amount of carboxamide, and employing stirring speed is that 100r / min stirring reaction 55min, obtains phosphoric acid di Slurry of potassium hydrogen;

[0058] (3) Cyclic crystallization and filtration: place the slurry obtained in step 2) in a cooling crystallizer to cool down to a temperature of 13°C, cool down to cyclic crystalliza...

Embodiment 3

[0063] A production method for preparing potassium dihydrogen phosphate by-product wolfberry special fertilizer, comprising the following steps:

[0064] (1) Preparation and mixing of raw materials: Put phosphoric acid and carbonamide in a stirred reactor at a molar ratio of 2.4:1, raise the temperature to 120°C at a heating rate of 11°C / min, and control the stirring speed of the stirring tank to 120r / min to stir Mixing reaction 2h, obtain intermediate slurry;

[0065] (2) Preparation of KH 2 PO 4 : Add alkaline potassium salt again and contain step 1) in the reaction kettle of the intermediate slurry that makes, and add-on is 3 times of the amount of carboxamide, and employing stirring speed is 85r / min stirring reaction 50min, obtains phosphoric acid di Slurry of potassium hydrogen;

[0066] (3) Cyclic crystallization and filtration: place the slurry obtained in step 2) in a cooling crystallizer to cool down to a temperature of 11°C, cool down to cyclic crystallization and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com