A dancing wheel detection mechanism capable of variable tension adjustment and control

A detection mechanism and tension adjustment technology, which is applied in the field of optical fiber precision winding, can solve the problems affecting the signal transmission performance of optical fiber winding, large compressive stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

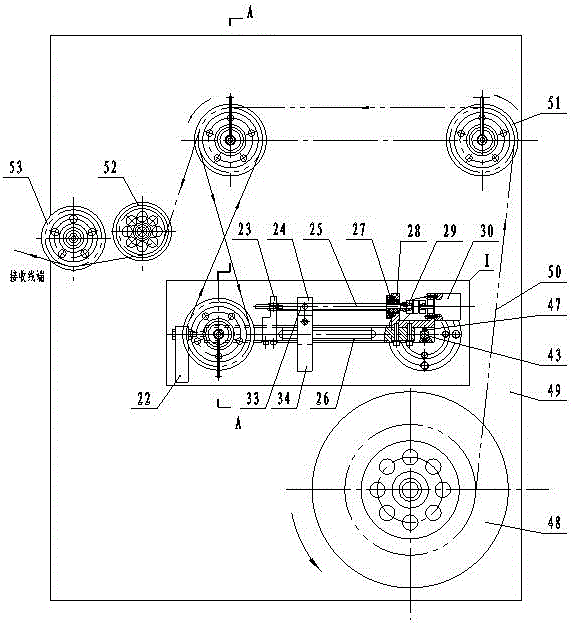

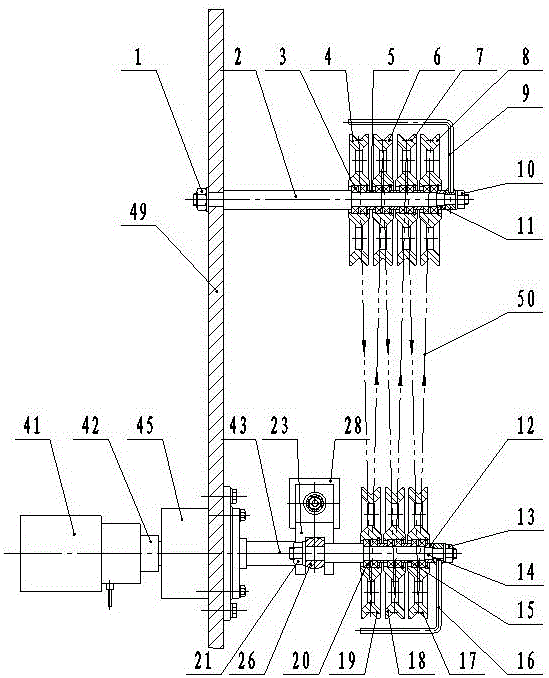

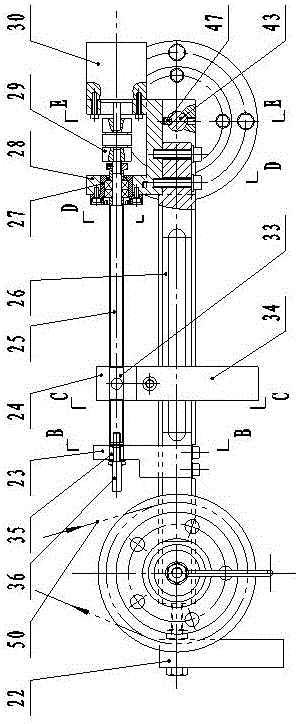

[0026] exist figure 1 and figure 2 Among them, the optical fiber 50 is released from the pay-off reel 48, and reaches the fixed wheel 4 after passing through the reversing wheel 1 51; the first time "8" is completed when the optical fiber 50 passes through the fixed wheel 1 4, the dancing wheel 19, and the fixed wheel 2 6 in sequence. When the optical fiber 50 passes through fixed wheel 2 6, dancing wheel 2 18, and fixed wheel 3 7, the second "8" cross-wrapping is completed, and the optical fiber 50 sequentially passes through fixed wheel 3 7, dancing wheel 3 17, and fixed wheel Four 8 o'clock complete the third time " 8 " shape crosses around; Like this optical fiber 50 order passes through fixed wheel one 4, dance wheel one 19, fixed wheel two 6, dance wheel two 18, fixed wheel three 7, dance wheel three 17, fix Pulley four 8, after three times of "8"-shaped cross-wrapping, is drawn from the fixed pulley four 8, and then reaches the take-up end through the tension detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com