Full double-screw extruder and BOPET thin film extrusion process using same

A twin-screw extruder and film technology, which is applied in the field of BOPET film processing, can solve the problems of high power consumption, inability to form films, and impact on melt quality, and achieve the effect of simple discharge of impurities and guaranteed efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

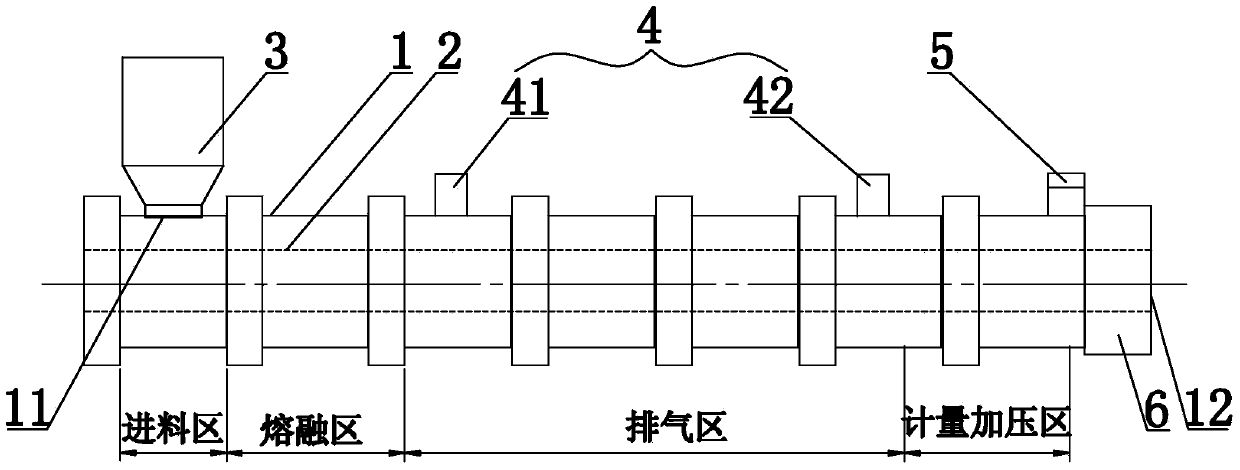

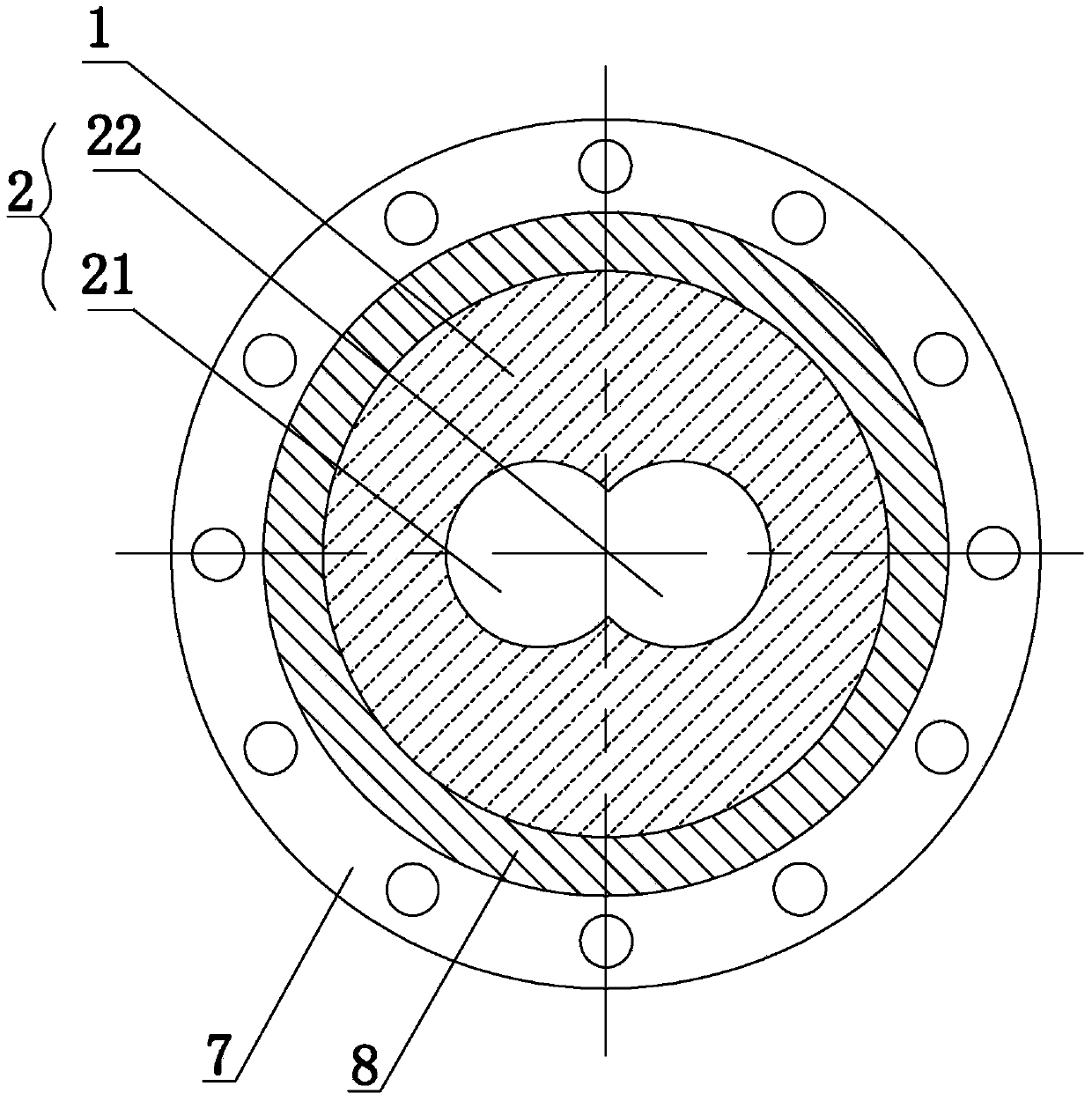

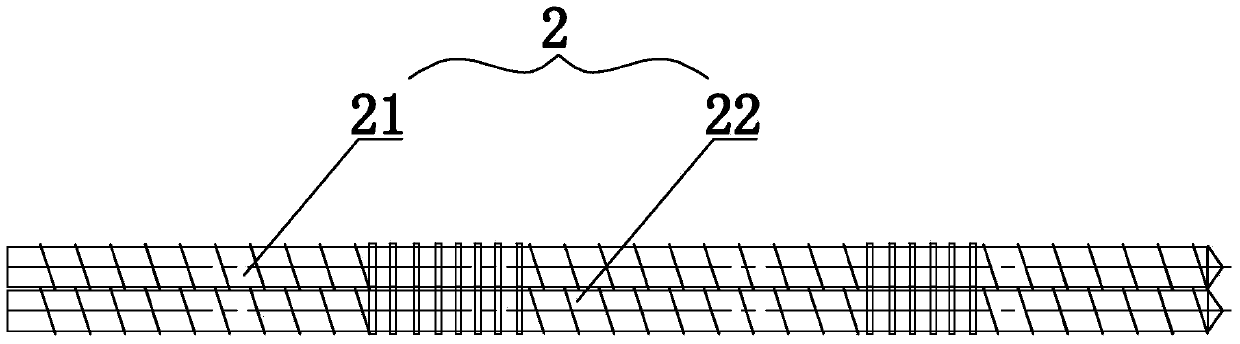

[0031] The full twin-screw extruder BOPET film production line of this embodiment combines figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, including extruding device, die head 6, stretching device and draft winding device connected in sequence, stretching device includes chill roll, longitudinal stretching part and transverse stretching part, stretching device passes chill roll and The die head is connected, and the transverse stretching part is connected with the drafting and winding device, wherein the extrusion device consists of a screw barrel 1, a twin screw 2 installed in the screw barrel 1, a feed port 3 arranged on the screw barrel 1, a row The air port 4 and the metering pump 5 are composed, the screw barrel 1 includes an inlet 11 and an outlet 12, the die head 6 is installed at the screw barrel outlet 12, the extrusion device is connected with the stretching device through the die head 6, and the feeding port 3 is arranged on the screw barrel At the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com