Vertical type water tank wire drawing machine

A water tank wire drawing machine, vertical technology, applied in the field of vertical water tank wire drawing machine, can solve the problems of low safety performance, difficult maintenance, long auxiliary time, etc., achieve safe and convenient operation, improve drawing times, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

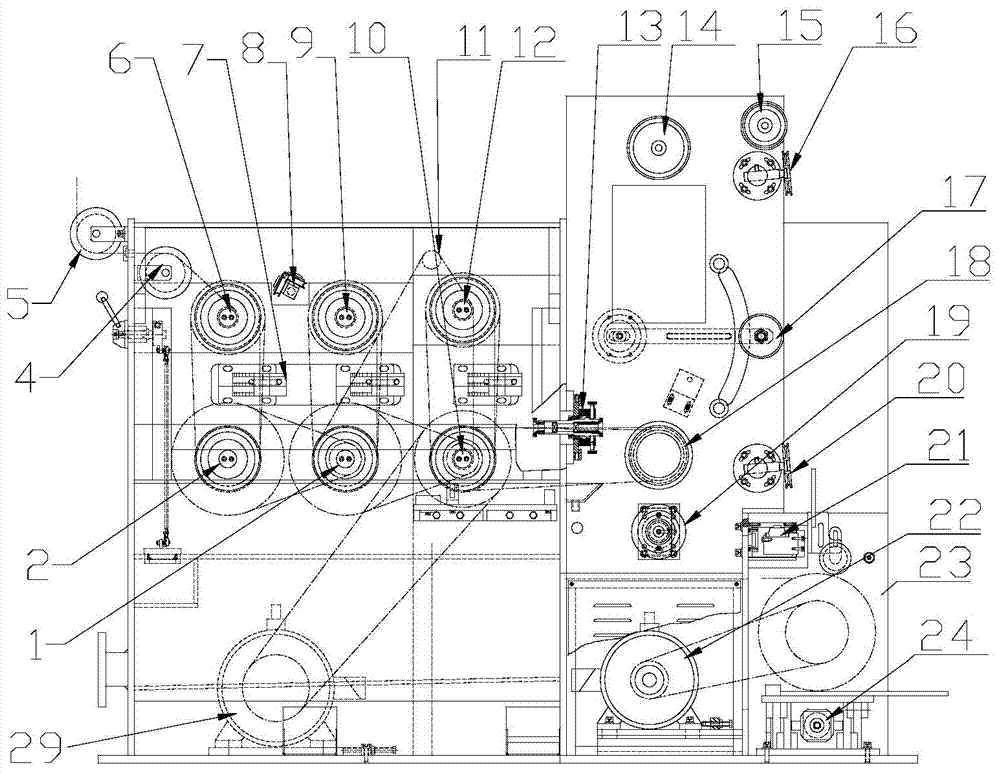

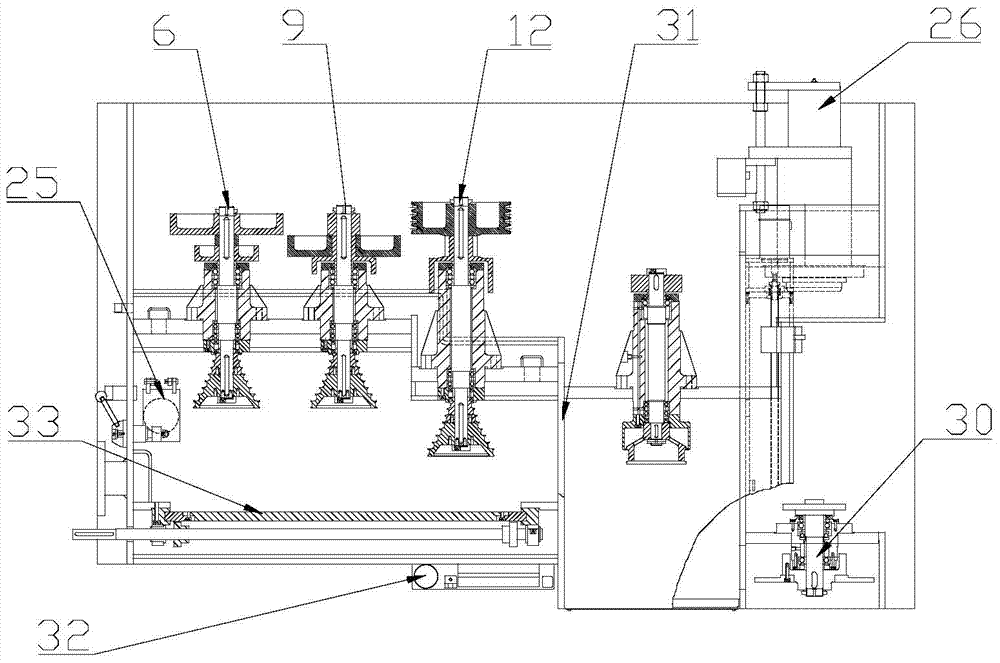

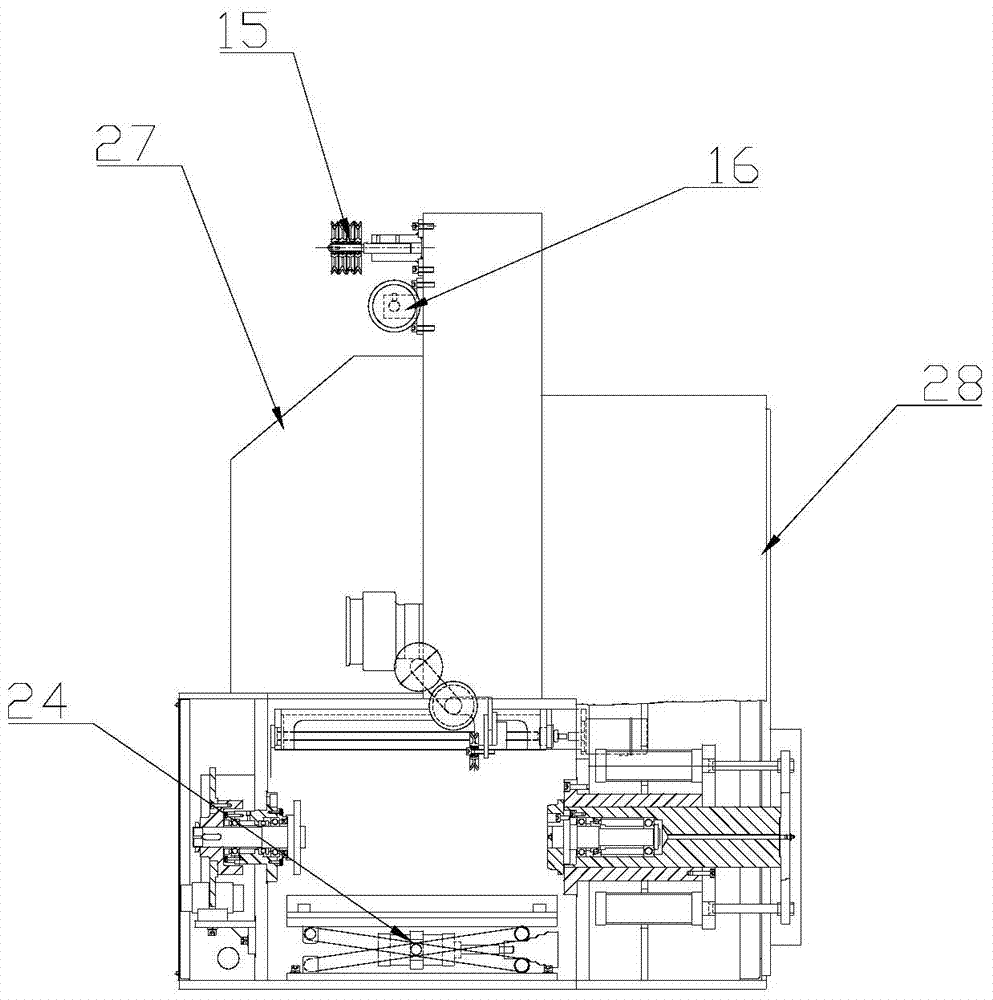

[0023] combine figure 1 , figure 2 with image 3 As shown, in this embodiment, the vertical water tank wire drawing machine includes several tower pulleys and corresponding wire drawing dies, a fine drawing die 13, a meter counting device 19, a traction wheel 18, a tension device 17, several wire passing devices, and a wire arranging device 17. Power device 29 and transmission device, the water tank wire drawing machine also includes a box body fixedly connected with the wire drawing machine frame, the tower pulley, the wire drawing die, the meter wheel, the traction wheel, the tension device, and several wire passing wheels The device, cable arrangement, power device and transmission device are all set in the box; the tower wheel includes three groups of tower wheels arranged in sequence, that is, the first tower wheel group (tape wheel group I), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com