Microporous bubbling air purifier

An air purifier and bubbling technology, which is applied in the field of gas purification devices, can solve the problems that the air purifier has not been successfully applied, is difficult to be practically applied, and has high gas phase resistance, achieves compact structure, and can control gas phase resistance and gas phase resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the embodiments of the present invention will be described in detail with reference to the drawings, and the objects, features, and effects of the present invention can be understood.

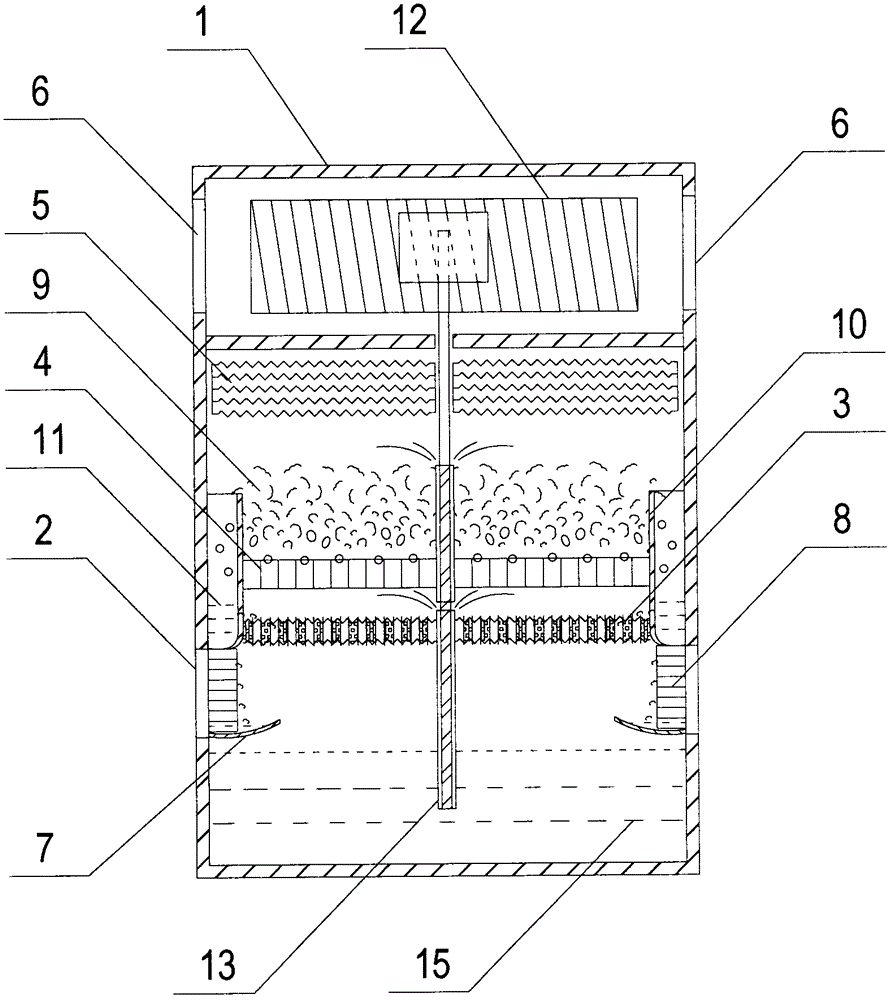

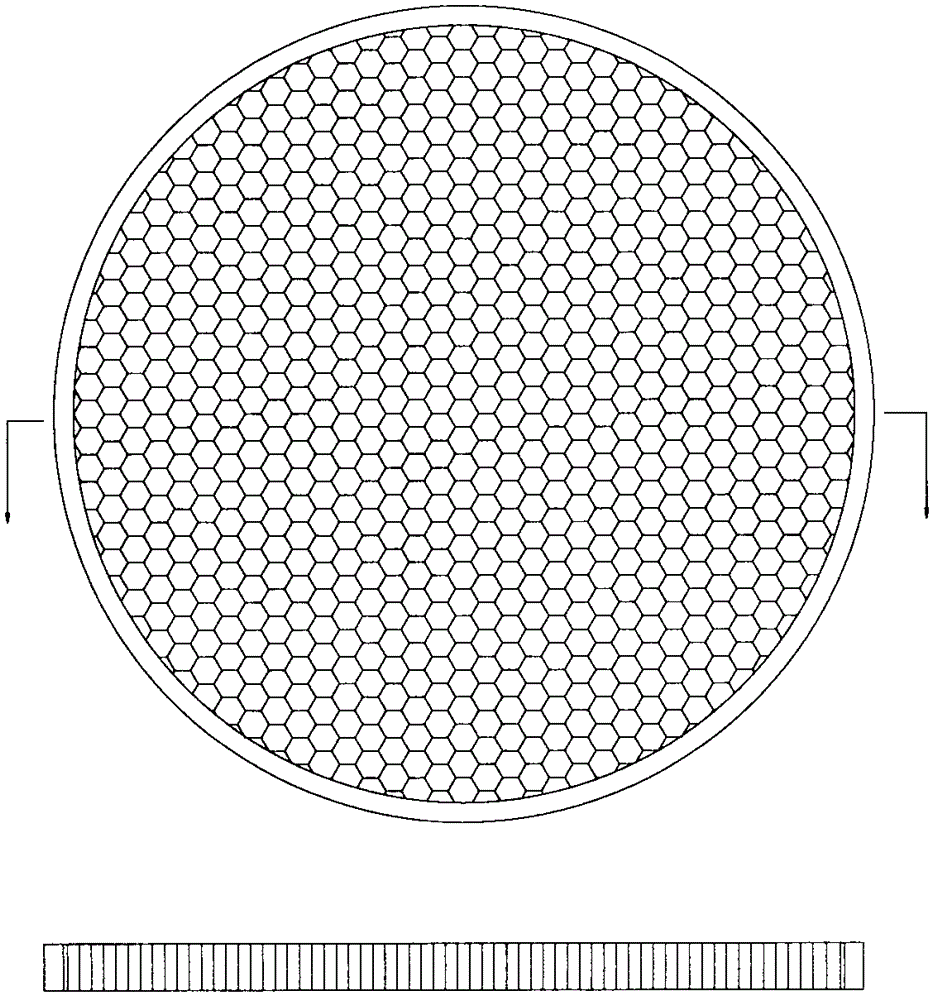

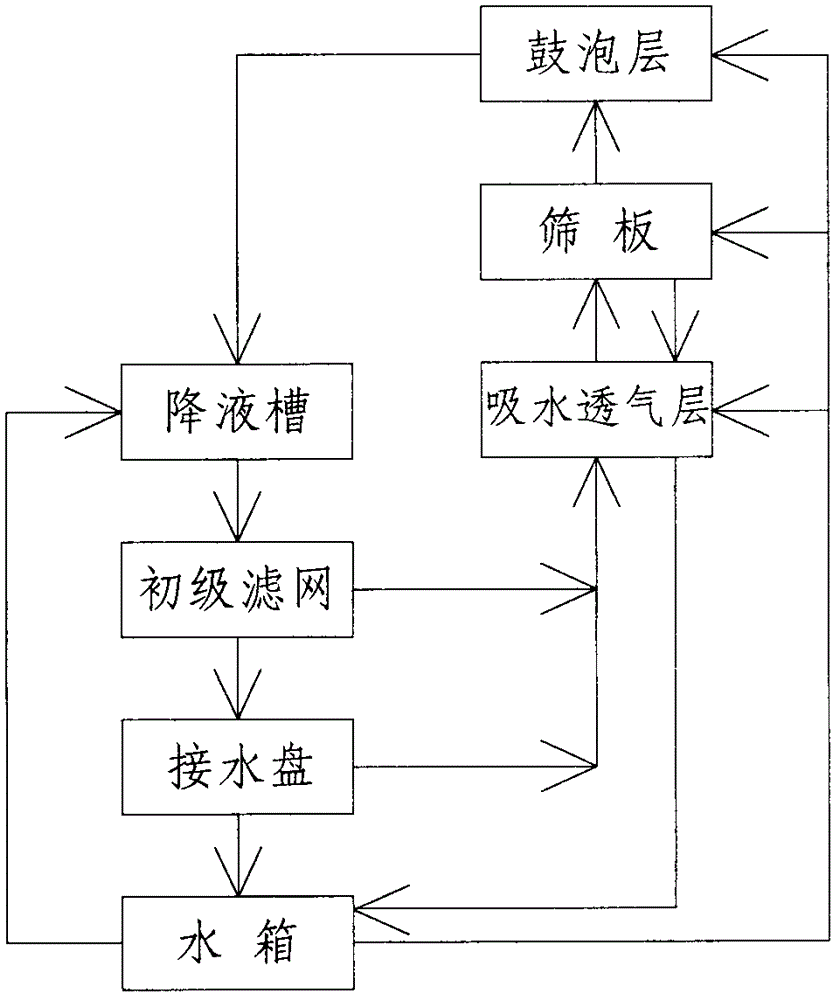

[0021] figure 1 It is a schematic cross-sectional view of the microporous bubbling air purifier of this embodiment. The microporous bubbling air purifier includes a housing 1, an air inlet 2, a water-absorbing and gas-permeable layer 3, a sieve plate 4, a mist removing layer 5, an air outlet 6, a liquid riser 13, a liquid droper, a fan 12 and a water tank 15. The water tank 15 is located at the bottom of the shell; the air inlet 2 is located at the lower part of the shell and above the liquid level of the water tank, and the air enters from one or both sides or around the shell; the demister layer 5 is located above the bubbling layer 9; the air outlet 6 is located in the upper part of the housing. The casing 1 and the air inlet 2 and the air outlet 6 constitute an air flow ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com