Micro-electromechanical reflector and method for manufacturing micro-electromechanical reflector

A reflector and micro-electromechanical technology, which is applied in the manufacture of micro-structure devices, processes for producing decorative surface effects, micro-structure technology, etc., can solve problems such as difficulty in deriving heat from the substrate, restrictions on the freedom of movement of electrodes or micro-mirrors, etc. , to achieve a stable conductive connection surface and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

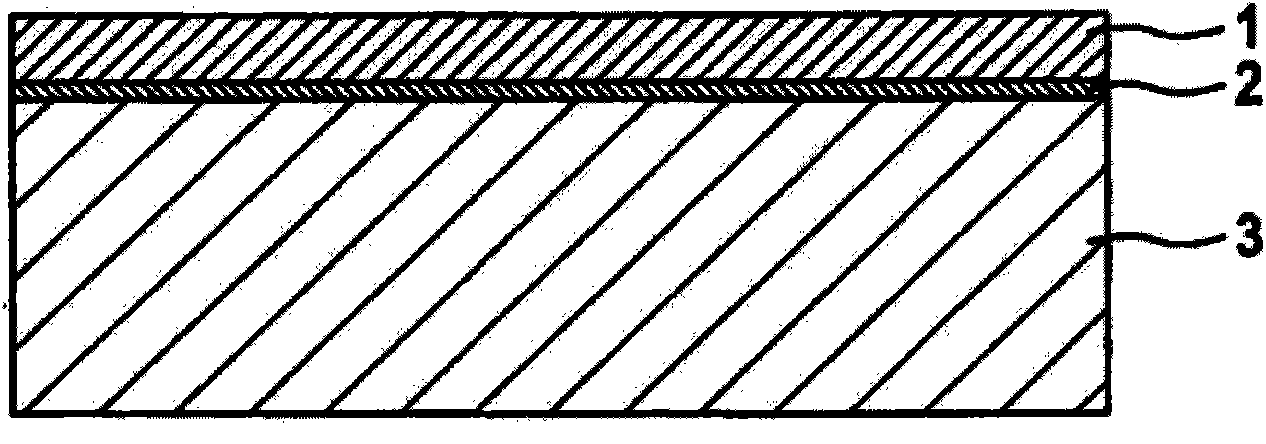

[0047] figure 1 A schematic diagram of a first intermediate product in the manufacture of a microelectromechanical reflector is shown in cross-section. In this case, the electrode substrate 3 can be provided with an oxide layer 2 which is applied to the surface of the electrode substrate 3 . A monocrystalline silicon layer 1 can then be applied on the oxide layer 2 . In one embodiment variant, the monocrystalline silicon layer 1 can be the first functional layer on a silicon-on-insulator wafer ("silicon an insulator: SOI wafer") as electrode substrate 3 .

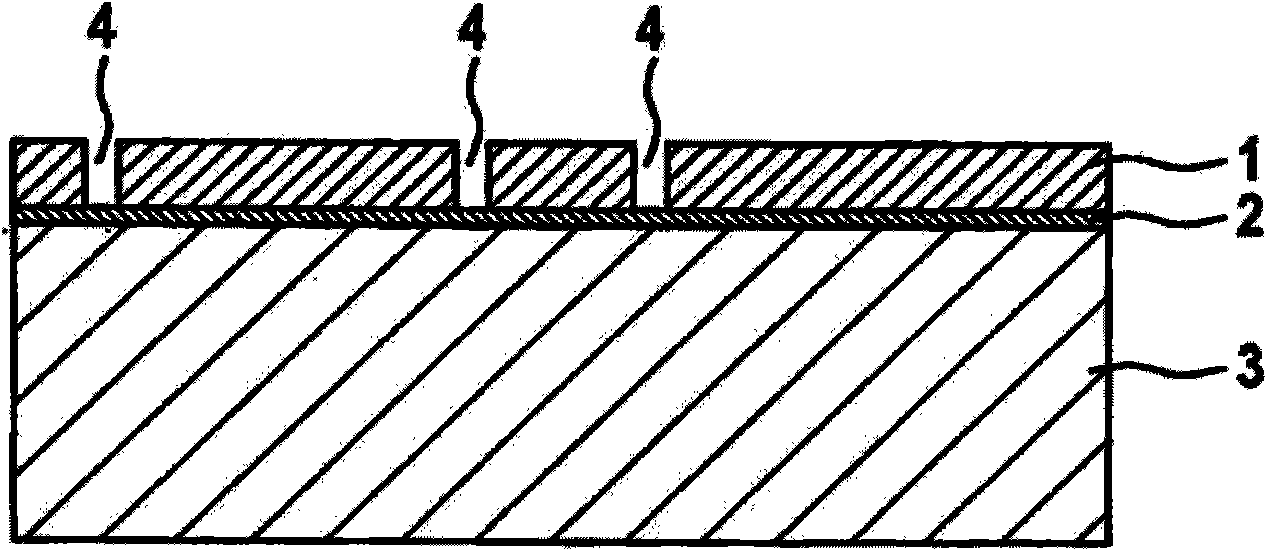

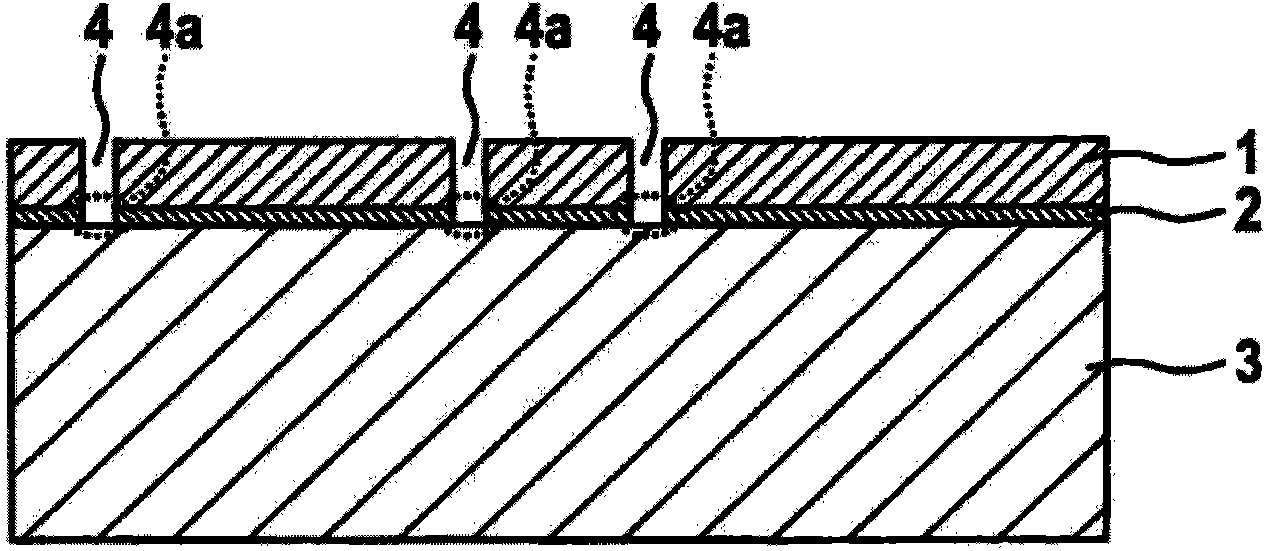

[0048] Such as figure 2 As shown, a via (Vias ("vertical interconnect access (vertical interconnect channel)") or a trench 4 can be provided in the monocrystalline silicon layer 1, which extends down to the oxide layer 2. As image 3 As shown, the oxide layer 2 is etched in the region of the via bottom or trench bottom 4 a, likewise up to the electrode substrate 3 .

[0049] Figure 4 Schematic showing one intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com