Semi-outsourcing bricking cast-in-place combined wall self-thermal-insulation system constructed by thermal insulation building blocks

A combined wall and self-insulation system technology, applied to walls, buildings, building materials, etc., can solve the problems of poor durability, poor fire safety, and poor rainwater leakage resistance, and achieve good energy-saving effects and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

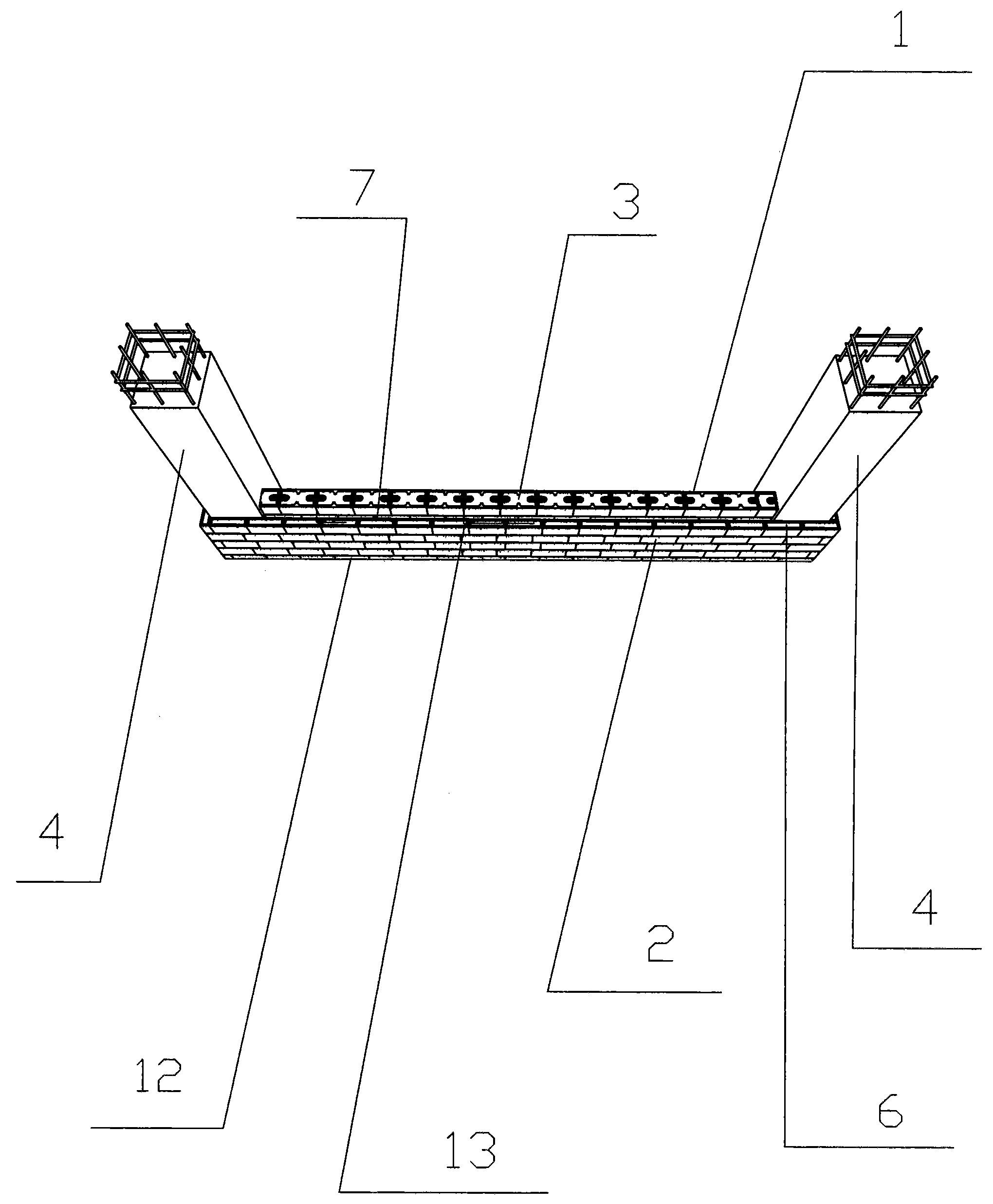

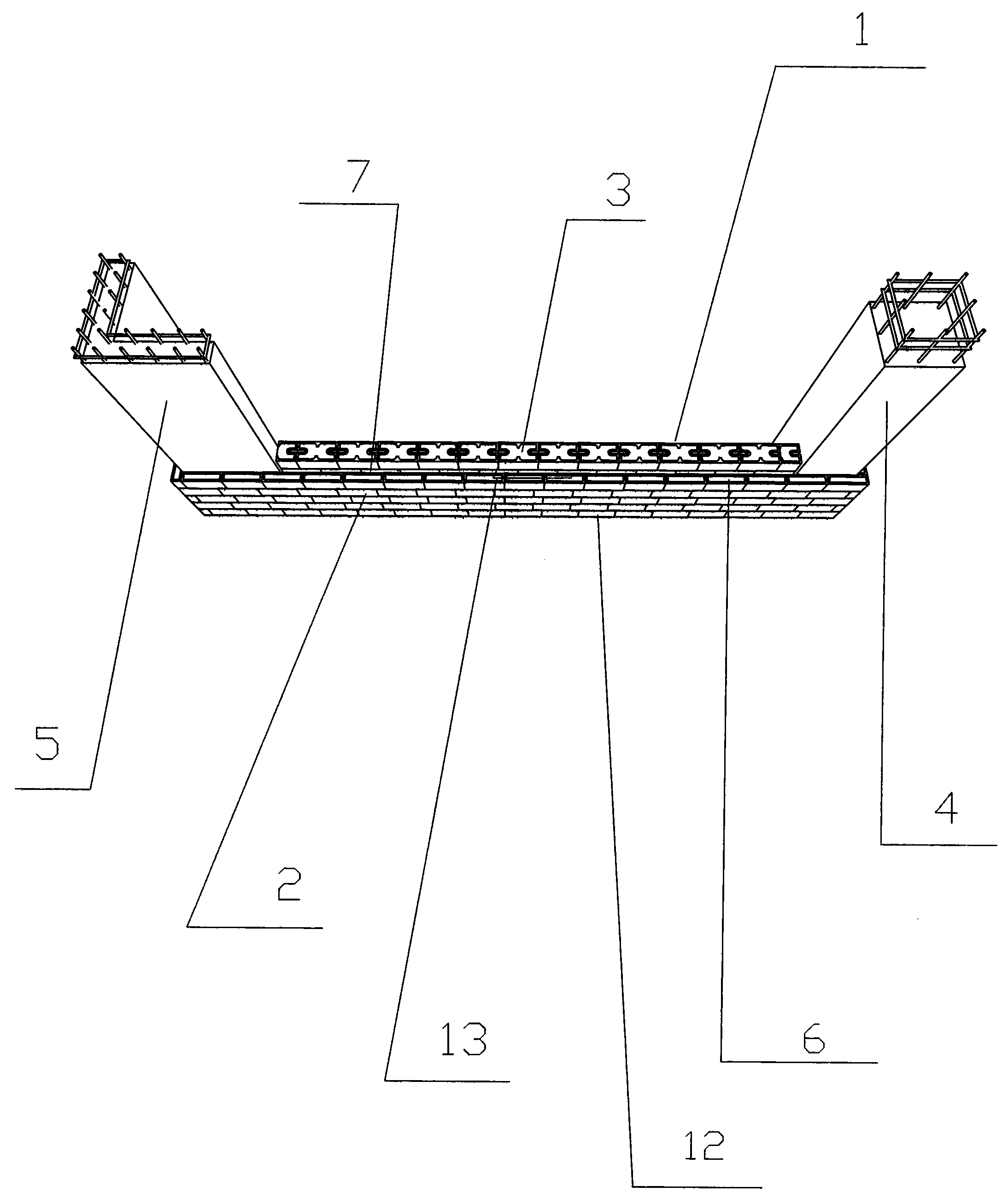

[0073] Such as figure 1 , Figure 4 As shown, a self-insulation system of a semi-outsourcing cast-in-place composite wall built with thermal insulation blocks is characterized in that the self-insulation system of a semi-outsourcing cast-in-place composite wall built with thermal insulation blocks includes A-type thermal insulation block self-insulation wall 1, B-type thermal insulation block self-insulation wall 2, oblique brick self-insulation wall and beam insulation body, insulation wall around doors and windows, top of lintel and wall top cast-in-place Insulation wall; the specific method and structure are as follows:

[0074] (1) Method and structure of A-type thermal insulation block self-insulation wall 1: use A-type thermal insulation block 3 to build A-type thermal insulation block self-insulation wall 1, and A-type thermal insulation block self-insulation wall 1 at both ends Connecting the column 4, the contact surface between the two ends of the A-type thermal in...

Embodiment

[0082] Such as Figure 5 As shown, a semi-outsourcing cast-in-place combined wall self-insulation system is characterized in that the semi-outsourcing cast-in-place combined wall self-insulation system includes A-type insulation block self-insulation wall 1, B-type insulation Block self-insulation wall 2, oblique brick self-insulation wall and beam insulation body, insulation wall around doors and windows, cast-in-place self-insulation wall at the upper end of the lintel and the top of the wall;

[0083] In this embodiment, the A-type thermal insulation block uses a single-cavity H-core composite thermal insulation block 14, the B-type thermal insulation block adopts a single-cavity inline composite thermal insulation block 18, and the C-type thermal insulation The composite thermal insulation block of font composite thermal insulation block 18, specific method and structure are as follows:

[0084] (1) Method and structure of A-type thermal insulation block self-insulation w...

Embodiment approach 2

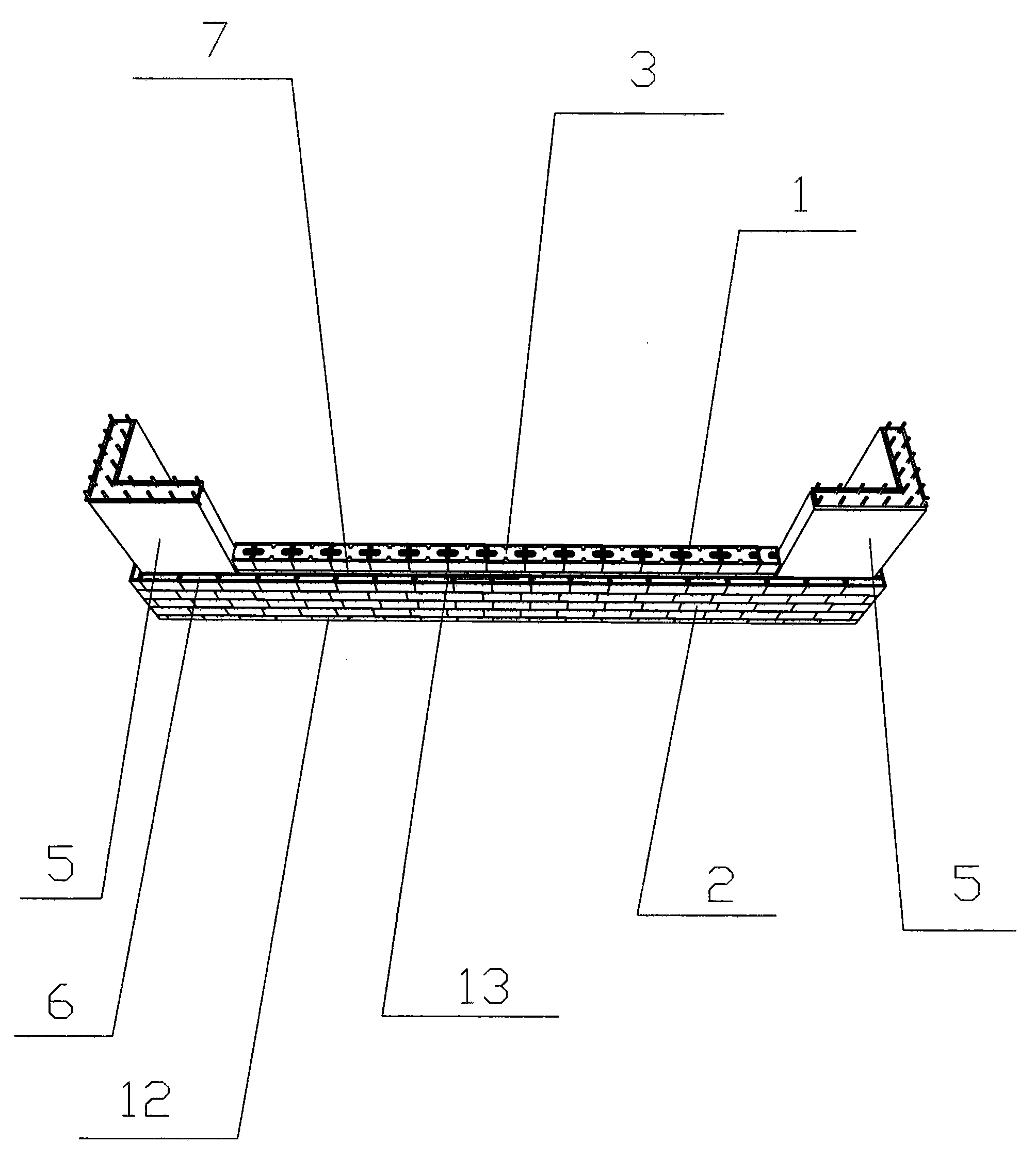

[0093] Such as figure 2 , Image 6 As shown, a self-insulation system of a semi-outsourcing cast-in-place composite wall built with thermal insulation blocks is characterized in that the self-insulation system of a semi-outsourcing cast-in-place composite wall built with thermal insulation blocks includes A-type thermal insulation block self-insulation wall 1, B-type thermal insulation block self-insulation wall 2, oblique brick self-insulation wall and beam insulation body, insulation wall around doors and windows, top of lintel and wall top cast-in-place Insulation wall; the specific method and structure are as follows:

[0094] (1) Method and structure of A-type thermal insulation block self-insulation wall 1: use A-type thermal insulation block 3 to build A-type thermal insulation block self-insulation wall 1, and A-type thermal insulation block self-insulation wall 1 at both ends To connect the shear wall 5, the contact surface between the two ends of the A-type therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com