Deburring device including visual sensor and force sensor

A vision sensor, burr removal technology, applied in instruments, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to obtain sufficient burr removal accuracy, increased cost, and difficulty in improving burr removal accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the attached drawings. In the illustrated embodiment, please note that the scales of the constituent elements are appropriately changed to facilitate understanding of the present invention. In the description of different embodiments, the same reference numerals are used for the same or corresponding structural elements, and overlapping descriptions are appropriately omitted.

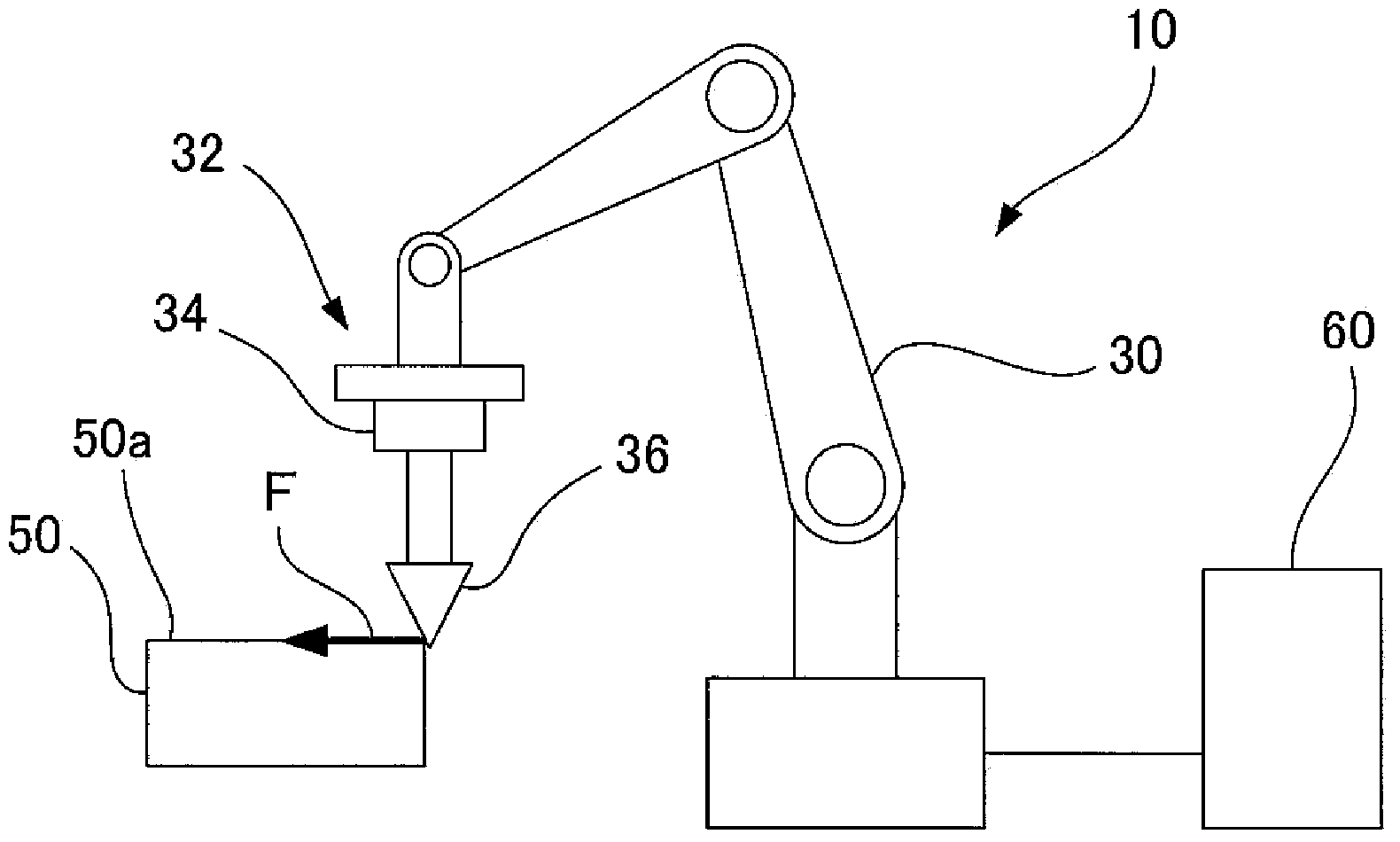

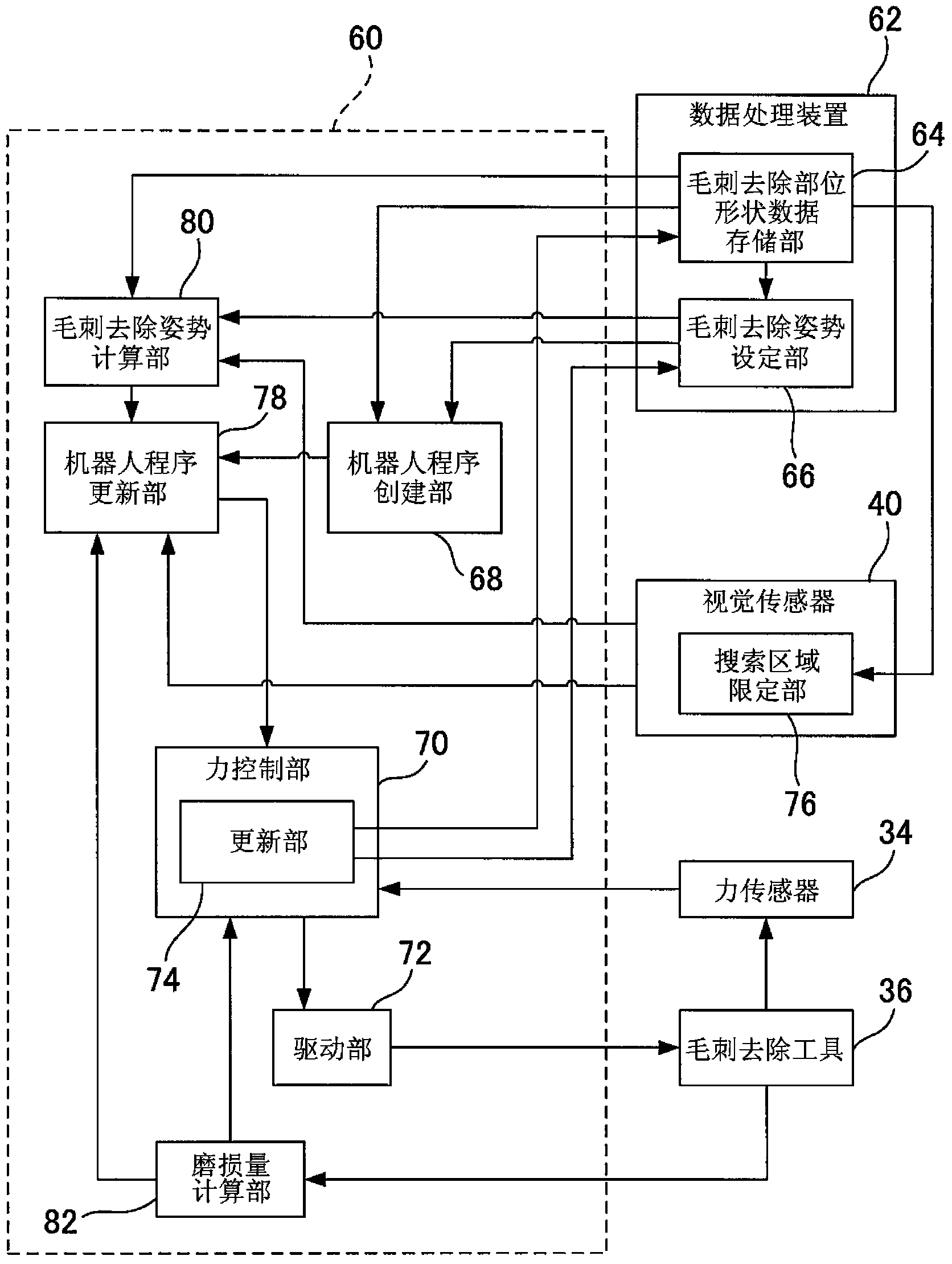

[0045] figure 1 It is a schematic diagram showing the configuration of the deburring device 10 according to the first embodiment of the present invention. The deburring device 10 includes: a articulated robot 30 having a plurality of arms; a force sensor 34 attached to a wrist 32 located at the front end of the arm of the robot 30; a deburring tool 36 attached to the force sensor 34; The control device 60 controls the robot 30 .

[0046] The robot 30 can take various positions and postures by rotating unillus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com