Dual drive floor scrubber

A floor and driving wheel technology, applied to manual floor scrubbing machines, cleaning floors, cleaning carpets, etc., can solve problems such as mobility/maneuverability restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be understood that the invention may assume various alternative orientations and step sequences unless expressly stated to the contrary herein. It should also be understood that the specific devices and processes shown in the drawings and described in the following description are merely exemplary embodiments of inventive concepts. Hence, no particular dimensions, orientations or other physical characteristics relating to the disclosed embodiments should be considered limiting unless expressly stated otherwise.

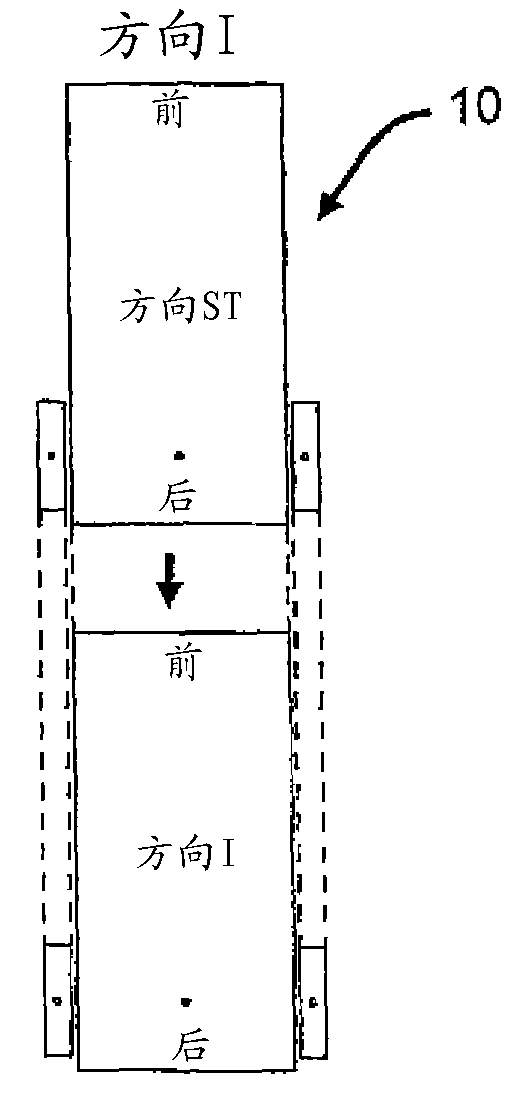

[0042] figure 1A ride-on floor cleaning / polishing machine 10 is shown having an analog joystick control 12, a power source 14, at least one cleaning tank 15, a right electric drive motor 16 and a left electric drive motor 18, a right motor controller portion 20 and a left The motor controller section 22 or a single motor controller 20 ′ controls the left and right motors and the right rear steering drive wheel 24 and the left rear steering drive whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com