A kind of metal wire film forming process method

A process method, metal wire technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of device short circuit, metal etching residue, etc., to improve the trend of growth, reduce metal residue, and improve device short circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

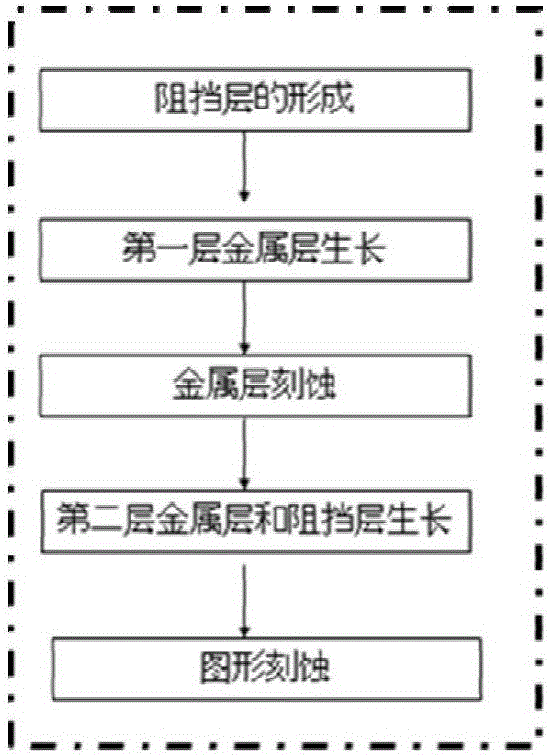

[0029] like figure 2 and Figure 3A As shown, a new method of metal wire film forming process of the present invention, the steps include:

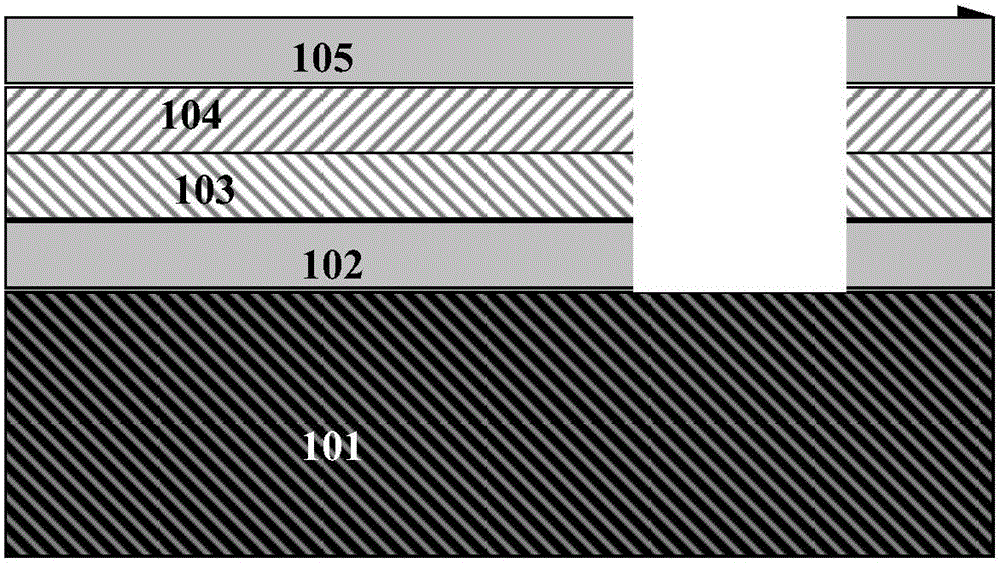

[0030] 1) Form a first barrier layer 102 on the substrate 101 to prevent damage to the substrate 101 during metal film formation; the first barrier layer 102 has a film thickness of It is TiN or a composite material of Ti and TiN.

[0031] 2) Form the first metal layer 103 on the first barrier layer 102; this step mainly adopts the physical sputtering film forming process, and the film thickness of the first metal layer 103 is The sputtering temperature is 10-500°C, and the pressure is 1-10torr;

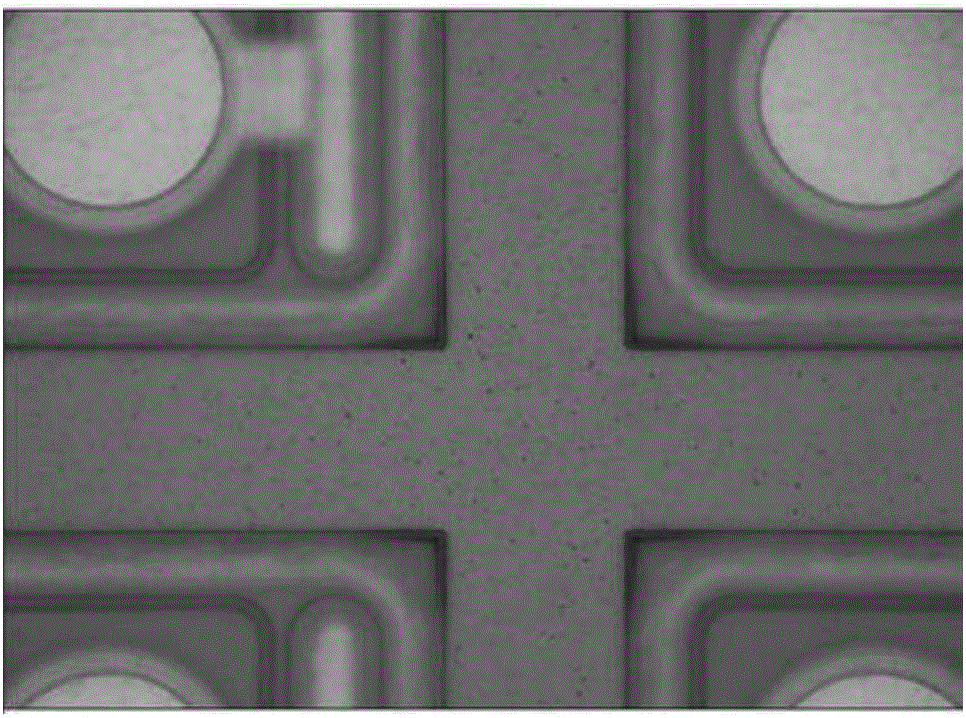

[0032] 3) A part of the first metal layer 103 is etched away by etching or other methods, and the film thickness ratio of the first metal layer 103 before and after etching is 100:90-1000:999; the etched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com