A photoionization mass spectrometry device for in situ detection of laser-heated reactor products

A technology of laser heating and in-situ detection, which is used in mass spectrometers, parts of particle separator tubes, sample introduction/extraction, etc. problem, to achieve the effect of narrow laser beam, space saving design, simplified heating and temperature measurement device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

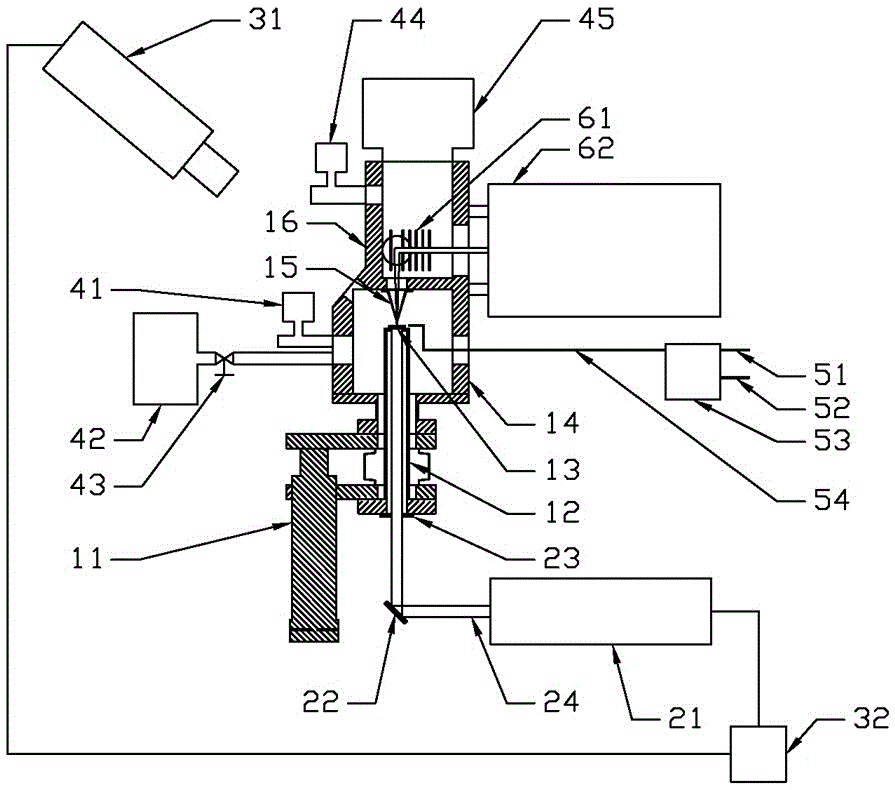

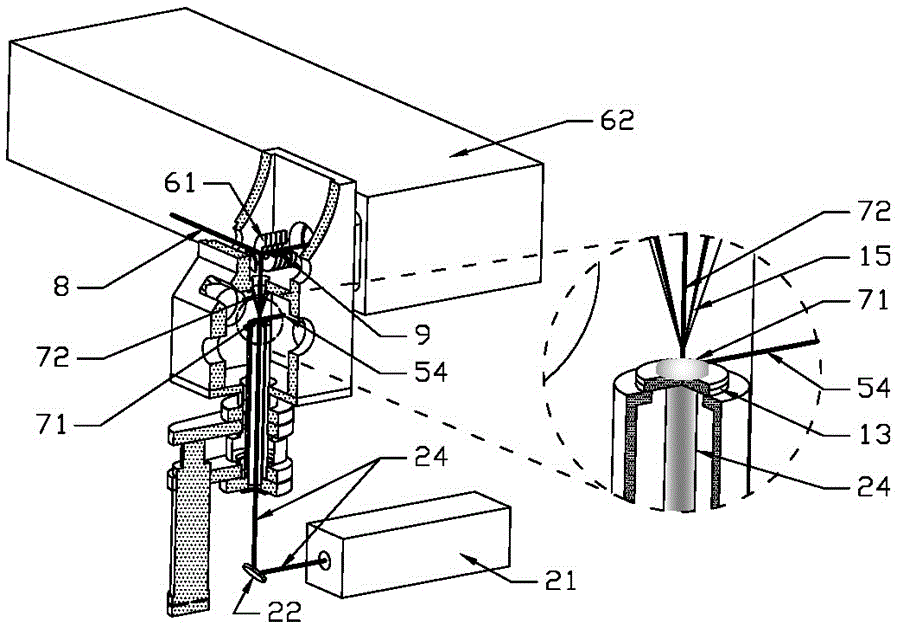

[0023] see figure 1 , a photoionization mass spectrometry device for in-situ detection of laser-heated reactor products, including a main cavity, a laser, a temperature measuring instrument 31 , a sampling mechanism and a mass spectrometer 62 .

[0024] The main cavity includes an ionization chamber 16, a reaction chamber 14, a vacuum linear drive mechanism 11, a laser transmission tube 12, and a sampling cone 15; The sampling hole, the sampling cone 15 is installed at the sampling hole on one side of the reaction chamber 14; the material of the sampling cone 15 is quartz, and the aperture at the top is 50-500 μm;

[0025] The upper part of the laser transmission tube 12 is located in the reaction chamber 14, the lower part is located outside the reaction chamber 14, and the lower part is installed on the vacuum linear drive mechanism 11; the upper end of the laser transmission tube 12 is equipped with a reaction base 13, and the reaction base 13 is located in the sampling con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com