Precise control method of sewage treatment plant aeration total quantity

A sewage treatment plant, precise control technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of adjustment lag, arbitrariness, low adjustment frequency, poor adaptability to changes in incoming water quality and water volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

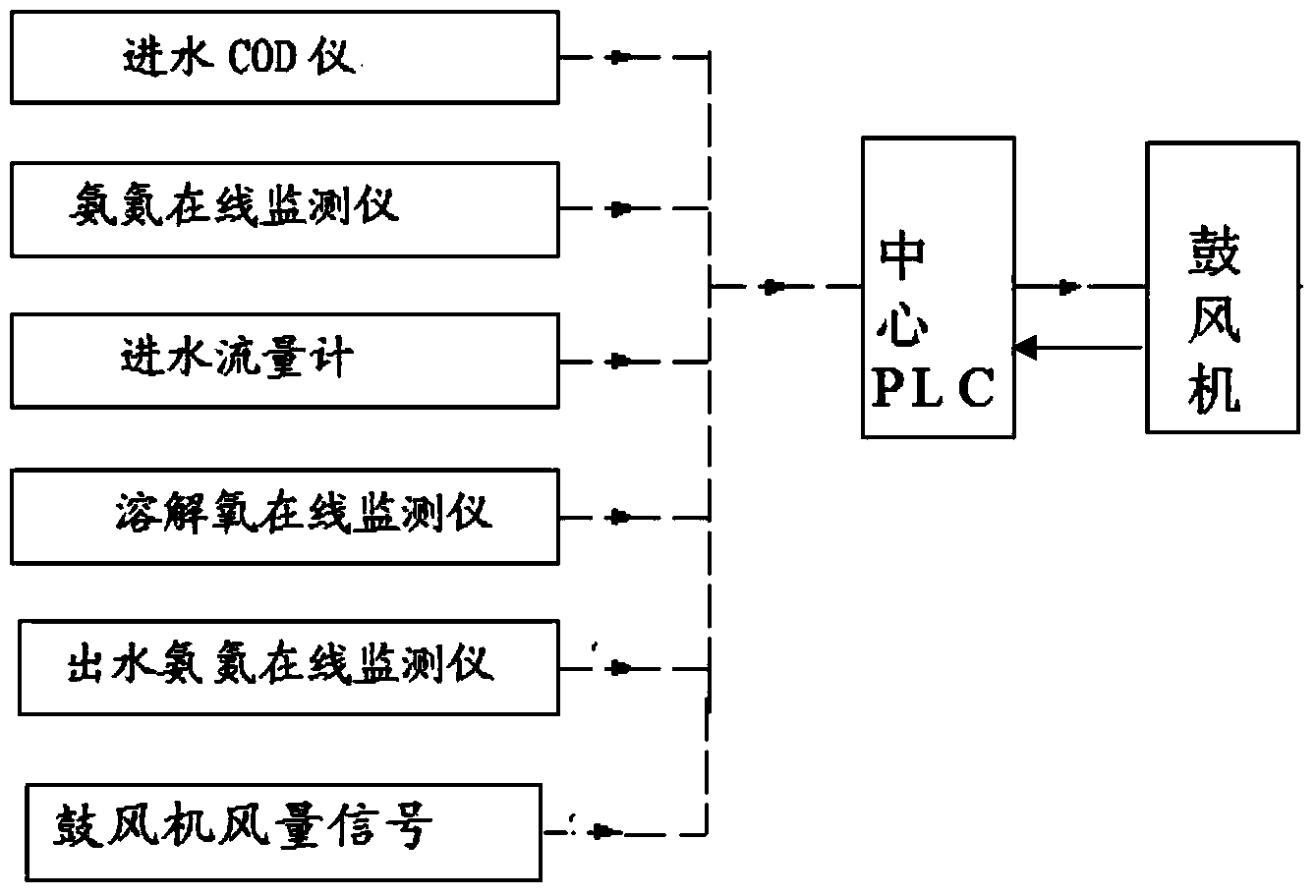

[0097] see attached figure 1 , attached Figure 4 , the present invention provides a precise control method for the total amount of aeration in a sewage treatment plant, including an influent COD instrument, an influent ammonia nitrogen online monitor, an influent flow meter, an online dissolved oxygen monitor, an effluent ammonia nitrogen online monitor, and a central PLC and several air blowers, the influent COD instrument, ammonia nitrogen on-line monitor, inflow flowmeter, dissolved oxygen on-line monitor and effluent ammonia nitrogen on-line monitor are connected in parallel to the central PLC, and the central PLC is connected to several air blowers ; The central PLC collects four variable signals with independent adjustment period and adjustment range respectively, i.e. effluent ammonia nitrogen, DO value, influent COD and ammonia nitrogen, influent water volume have primary and secondary, and four interrelated Variable signal, the four variable signals are uniformly de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com