Water-sensitive fluorescence enhanced test paper as well as preparation method and application thereof

A technology of fluorescence enhancement and test paper, which is applied in the application field of fluorescent carbon nanomaterials, to achieve the effect of low cost, strong photobleaching resistance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the above-mentioned amphiphilic carbon nano-dots: functionalize part of the hydrophilic groups on the surface of the water-soluble carbon nano-dots into lipophilic groups, generally functionalize 30-80% of the hydrophilic groups into lipophilic groups group.

[0043] The present invention provides a method for preparing amphiphilic carbon nano-dots, but is not limited thereto:

[0044] (1) Add water-soluble carbon nano-dots, lipophilic compounds containing substituents, catalysts and solvents into the reaction device, stir evenly, and heat to reflux, so that water-soluble carbon nano-dots and lipophilic compounds undergo condensation reactions or substitution reactions to obtain solution after reaction;

[0045] Among them, the mass ratio of water-soluble carbon nano-dots and lipophilic compounds containing substituents is 1: (5-30), the catalyst is added in corresponding proportions according to the prior art,...

Embodiment 1

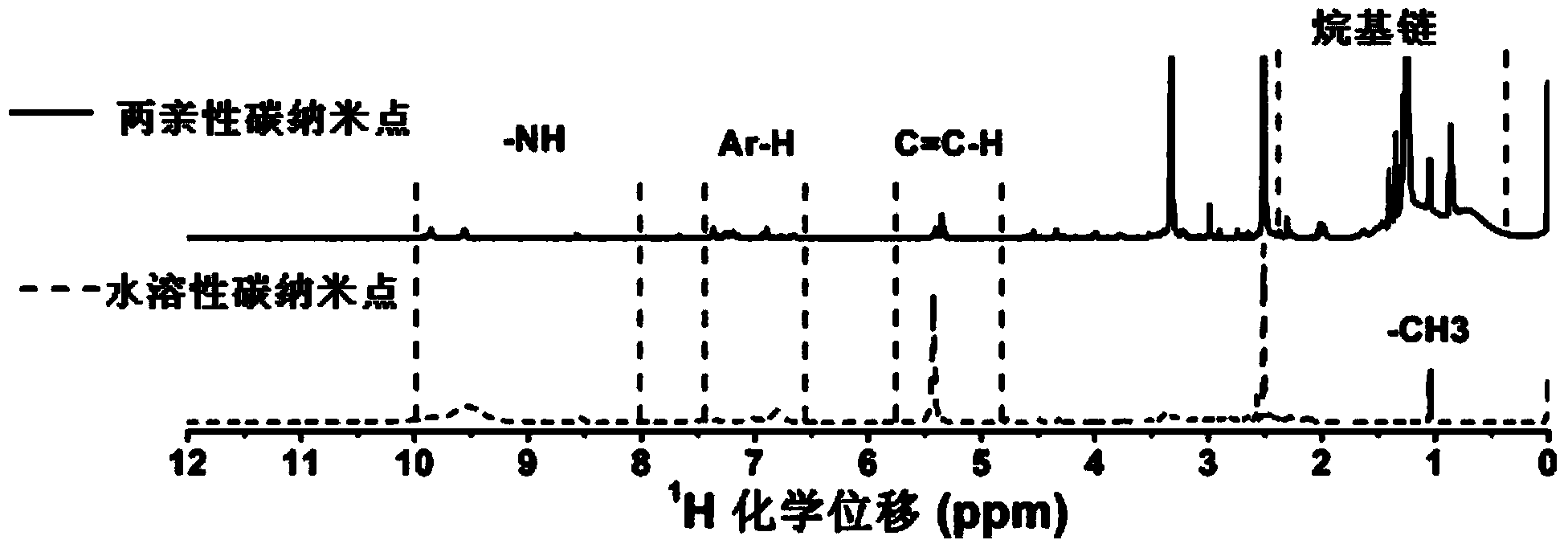

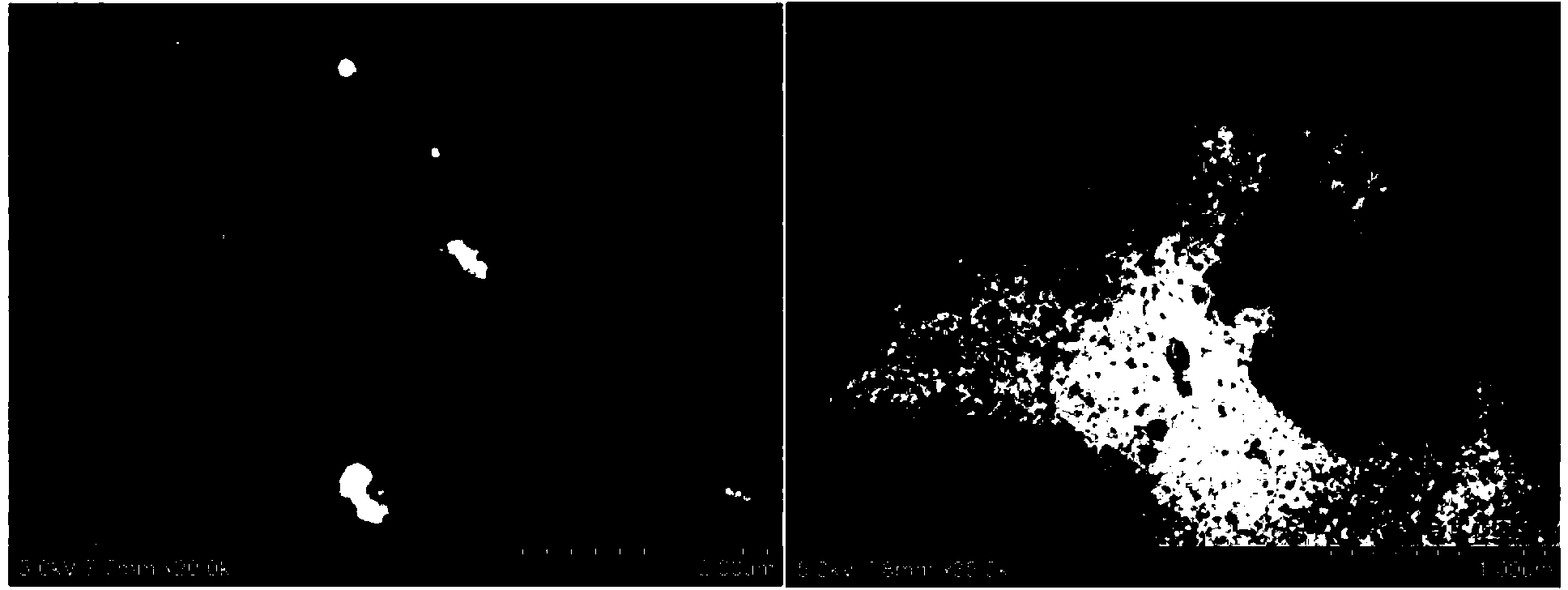

[0066] combined with Figure 1-4 Illustrative Example 1

[0067] Preparation of amphiphilic fluorescent carbon nanodots:

[0068] (1) Weigh 3g citric acid (C 6 h 8 o 7 ·H 2 O) and 6g urea (CH4N2O) are blended in a clean beaker, add 20mL of deionized water and fully stir to make it dissolve; then transfer to a microwave oven and heat for 4min under 1000w power to obtain a black coke-like paste solid; then The beaker is placed in a blast drying oven for 1 hour to obtain water-soluble carbon nanodots;

[0069] (2) Weigh 0.6g water-soluble carbon nano-dots, 4g anhydrous potassium carbonate (Tianjin Guangfu Fine Chemical Research Institute), 0.4g potassium iodide (Tianjin Fengchuan Chemical Reagent Technology Co., Ltd.), 60mLN, N-dimethyl Formamide (Xilong Chemical Co., Ltd.), 2.4mL bromododecane (Tianjin Guangfu Fine Chemical Research Institute) were blended in a 250mL Erlenmeyer flask, and a 4cm cylindrical stirrer was stirred at 600 rpm at 180°C. Heating under reflux for ...

Embodiment 2

[0074] The hydrophilic groups of the amphiphilic carbon nano-dots are carboxyl groups and / or hydroxyl groups, and the lipophilic groups are propenyl groups;

[0075] The preparation method of the above-mentioned amphiphilic carbon nano-dots:

[0076] Weigh 0.6g of water-soluble carbon nanodots, 60mL of N, N-dimethylformamide (Xilong Chemical Co., Ltd.), 1.4mL of acrylamine (Tianjin Guangfu Fine Chemical Research Institute) and blend them in a 250mL Erlenmeyer flask. Add 2 mL of concentrated sulfuric acid, heat and reflux for 8 hours; after the reaction, filter the reacted solution twice with a suction filter, then distill under reduced pressure at 150°C until the solvent is completely evaporated to dryness; add the reaction product to 20 mL of n-hexane Dissolve in medium (lipophilic carbon nano-dots and amphiphilic carbon nano-dots are dissolved in n-hexane); centrifuge the n-hexane solution in which the carbon nano-dots are dissolved at high speed to obtain the desired amphip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com