Electromagnetic Action Dynamometer

An electromagnetic actuation and dynamometer technology, applied in power metering, measuring devices, instruments, etc., can solve problems such as easy leakage of hydraulic system seals, difficulty in improving position control accuracy, pollution of hydraulic oil environment, etc. Effects of maintenance costs, simple wiring, small environmental pollution and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Such as figure 1 As shown: the dynamometer includes a main part I, a control cabinet II connected to the main part I, and a host computer PC III connected to the control cabinet II. It is characterized in that the main part I uses two symmetrically arranged linear motors as power source, a linear encoder is used for the position closed-loop control of the linear motor, and a proximity switch is used for the stroke limit control of the linear motor.

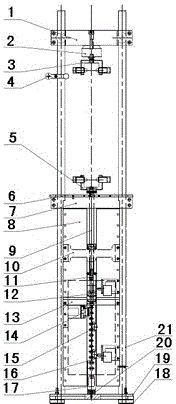

[0022] Such as figure 2 , 3 , 4, 5, 6, and 7: the main part I includes: top guide post fixing seat 1, force sensor 2, shock absorber upper end fixing seat 3, temperature sensor fixing bracket 4, shock absorber lower end fixing seat 5. Upper fixing plate 6, upper guide plate 7, left linear motor stator 8a, right linear motor stator 8b, sliding part 9, upper stator pressure plate 10, left and right linear motor movers 11, linear encoder 12, middle stator pressure plate 13 , grating probe 14, limit block 15, proximity swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com