Wave direction detection device of wave buoy

A verification device and wave buoy technology, applied in measurement devices, instruments, etc., can solve problems such as horizontal acceleration interference, achieve the effects of simple structure design, improve maintainability and reliability, and avoid horizontal acceleration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

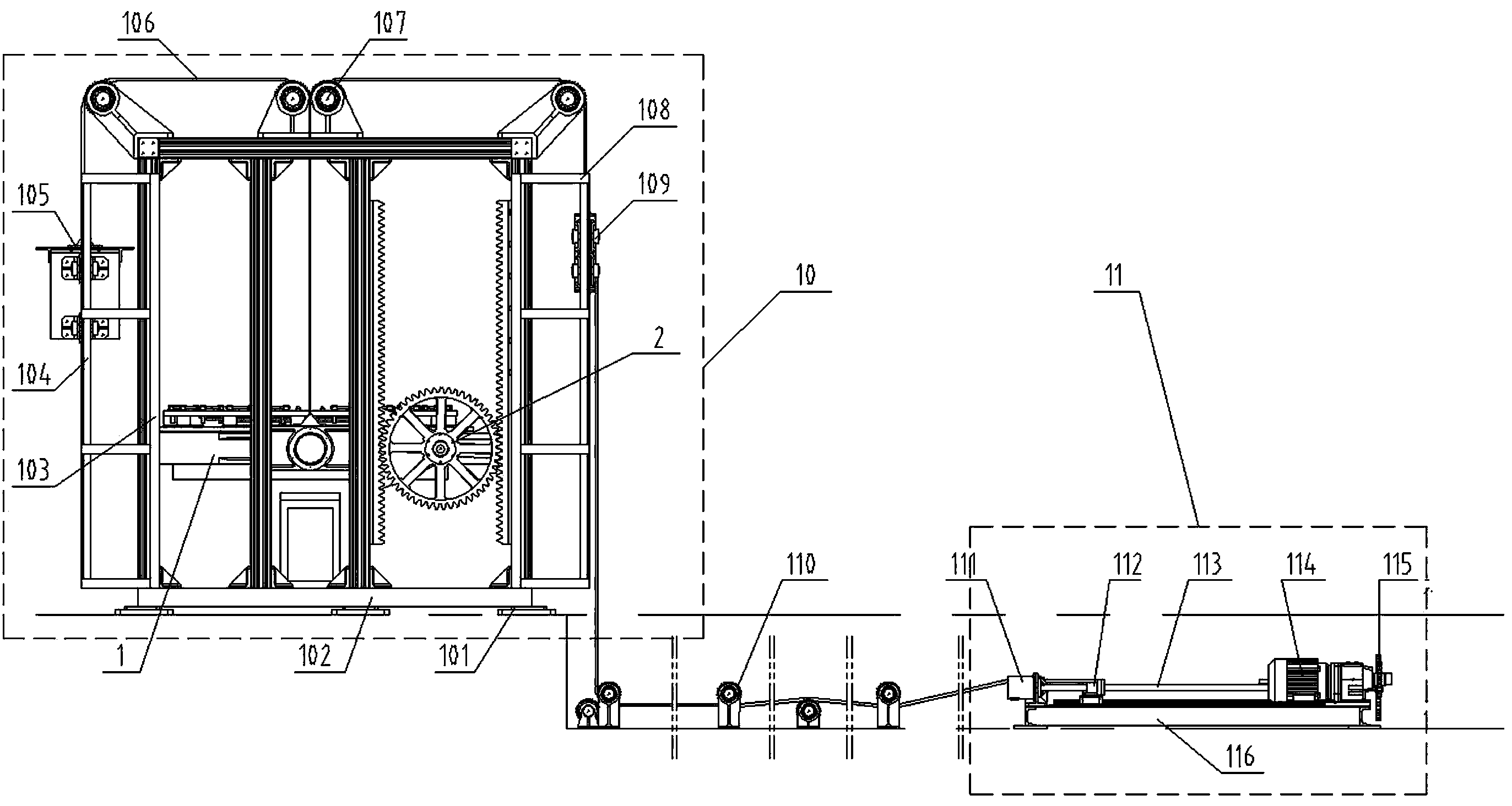

Method used

Image

Examples

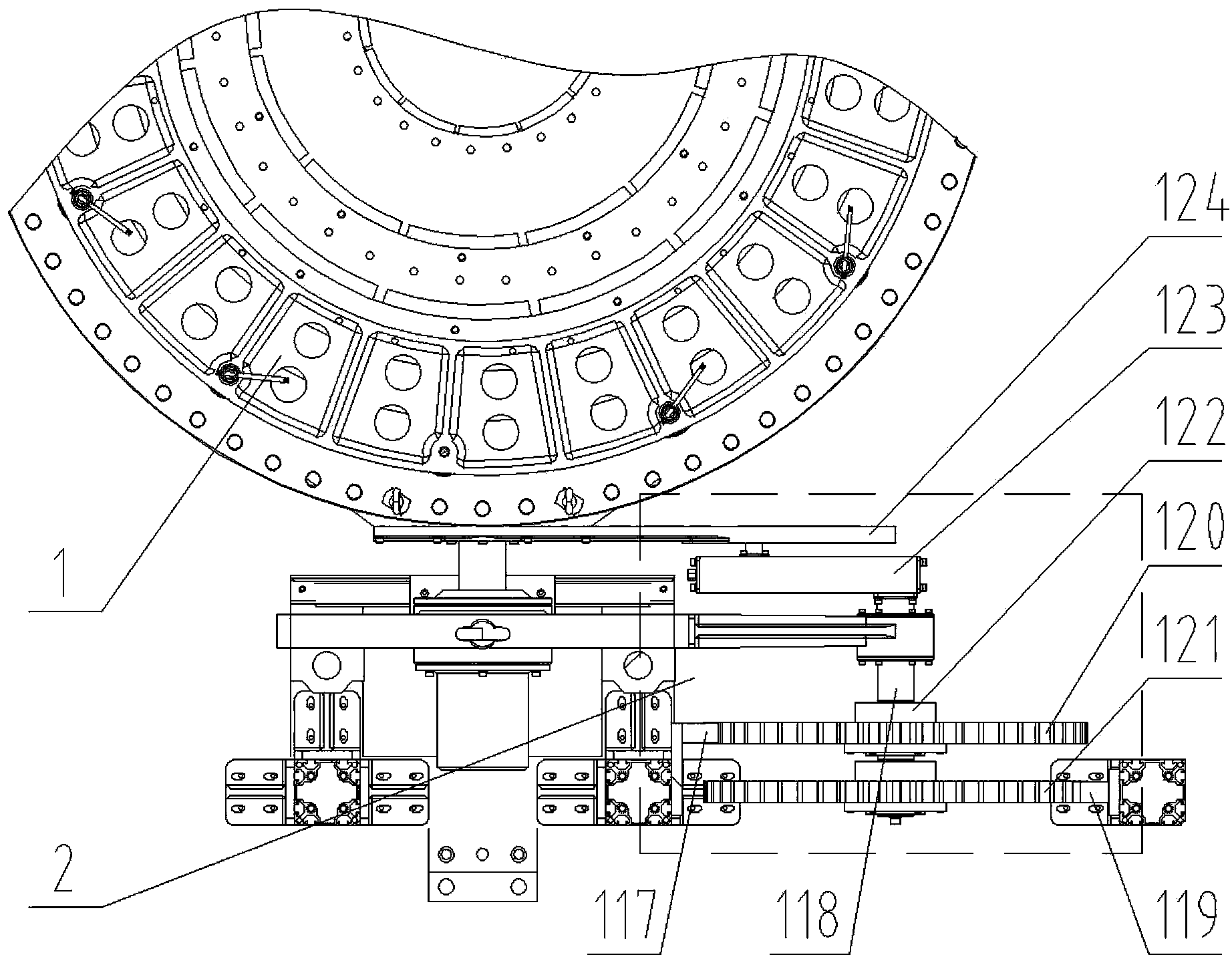

Embodiment Construction

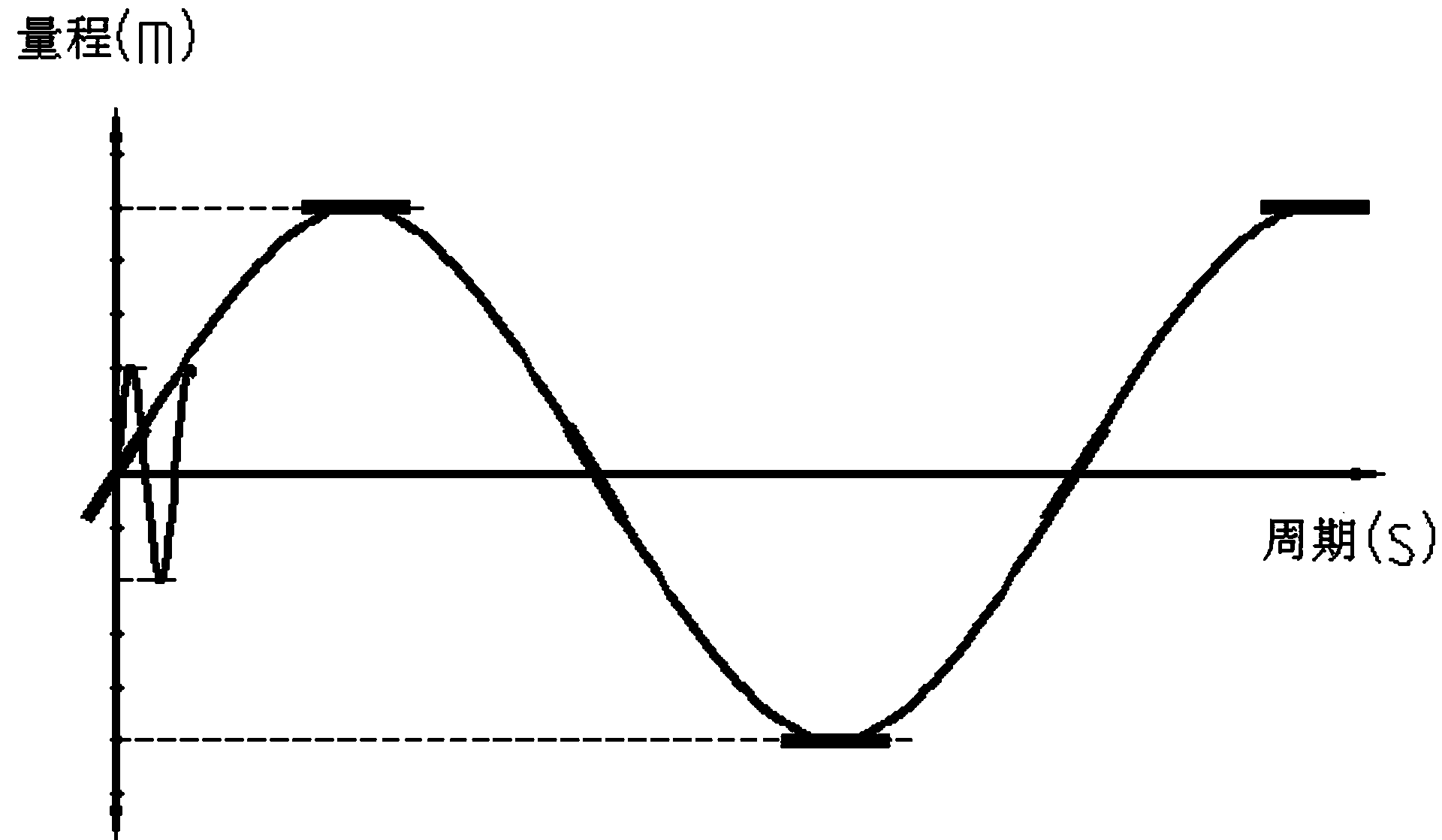

[0025] To measure the wave direction is to use the wave height tilt sensor and the azimuth sensor above it to measure the wave direction parameters. When the buoy tilts with the wave surface, the pendulum keeps a "vertical state" around its center of gravity, and the pendulum axis rotates clockwise or counterclockwise at different angles of the pendulum. By measuring the size and direction of the rotation angle of the pendulum axis, two sets of parameters of the pitch and heel of the buoy along with the wave surface can be obtained. Using these two sets of parameters, the azimuth of the buoy's inclination can be calculated, and this azimuth also reflects the direction of the wave surface inclination. However, the tilt direction of the wave surface calculated by measuring the rotation angle and direction of the pendulum shaft is relative to the direction of the baseline measured by the tilt sensor itself. This relative direction is corrected by the buoy azimuth measured by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com