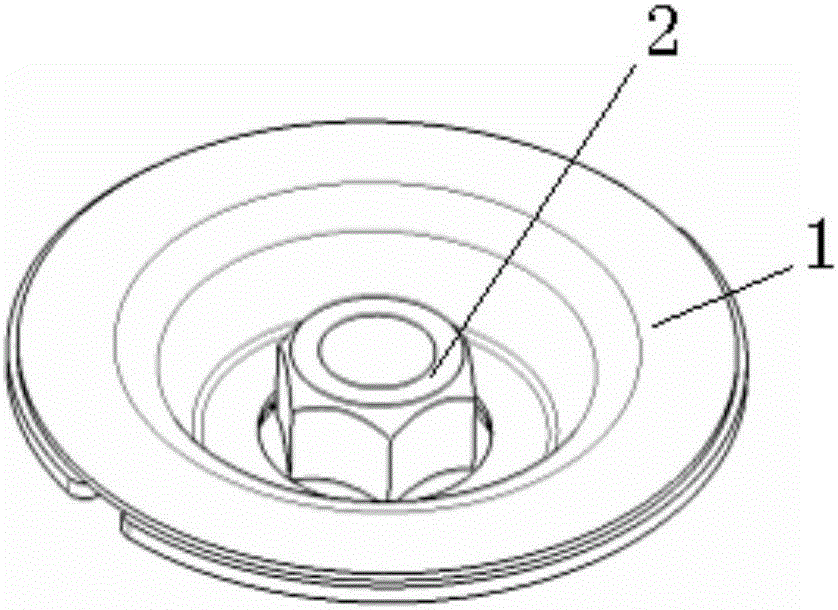

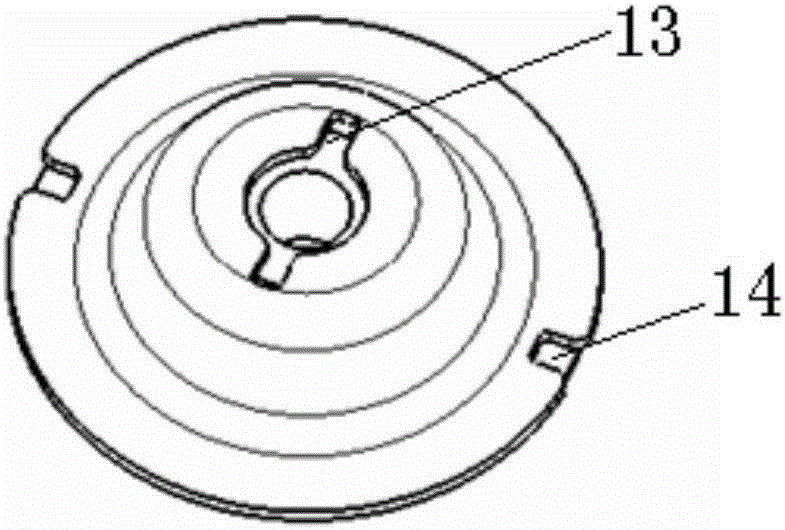

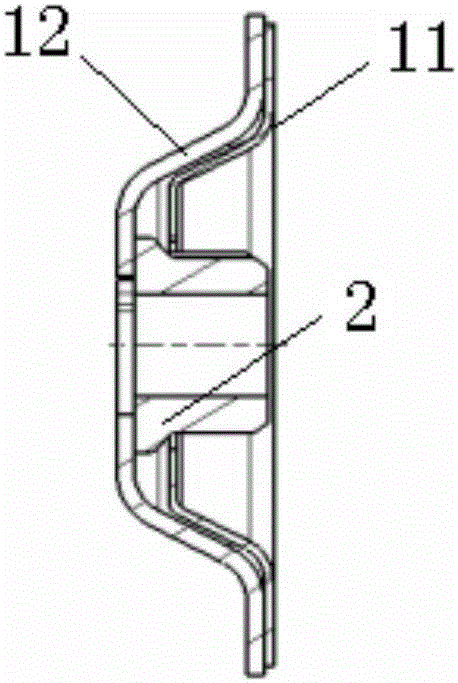

A shock absorber mounting end cover assembly with integrated nut

An integrated nut and mounting end technology, applied in the field of automobile vibration reduction, can solve the problems of limited production and assembly cycle, slipping and breaking of the piston rod slot, and achieve the effect of avoiding low efficiency of process cycle and avoiding torque loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention are described below through specific examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations on the technical solutions of the present invention.

[0039] The invention relates to a shock absorber installation end cover assembly with integrated nuts. In order to accelerate the attenuation of the vibration of the frame and the body and improve the ride comfort (comfort) of the car, the suspension system of most cars is equipped with a shock absorber. The shock absorber can quickly eliminate the vibration of the shaft and wheels caused by the road surface, and ensure that the wheels can grip the ground at any time, thereby ensuring the steering and braking functions of the vehicle and improving the safety of the vehicle.

[0040] The shock absorber is a vulnerable part during the use of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com