A bottom expansion drill bit

A bottom-expanding drill bit and drill rod technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems that the upper arm and the lower arm cannot be returned, cannot be pulled out smoothly from the hole, and the upper arm and the lower arm are easy to deform, etc. , to achieve the effect of flexible and convenient dislocation and recovery, low design and production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

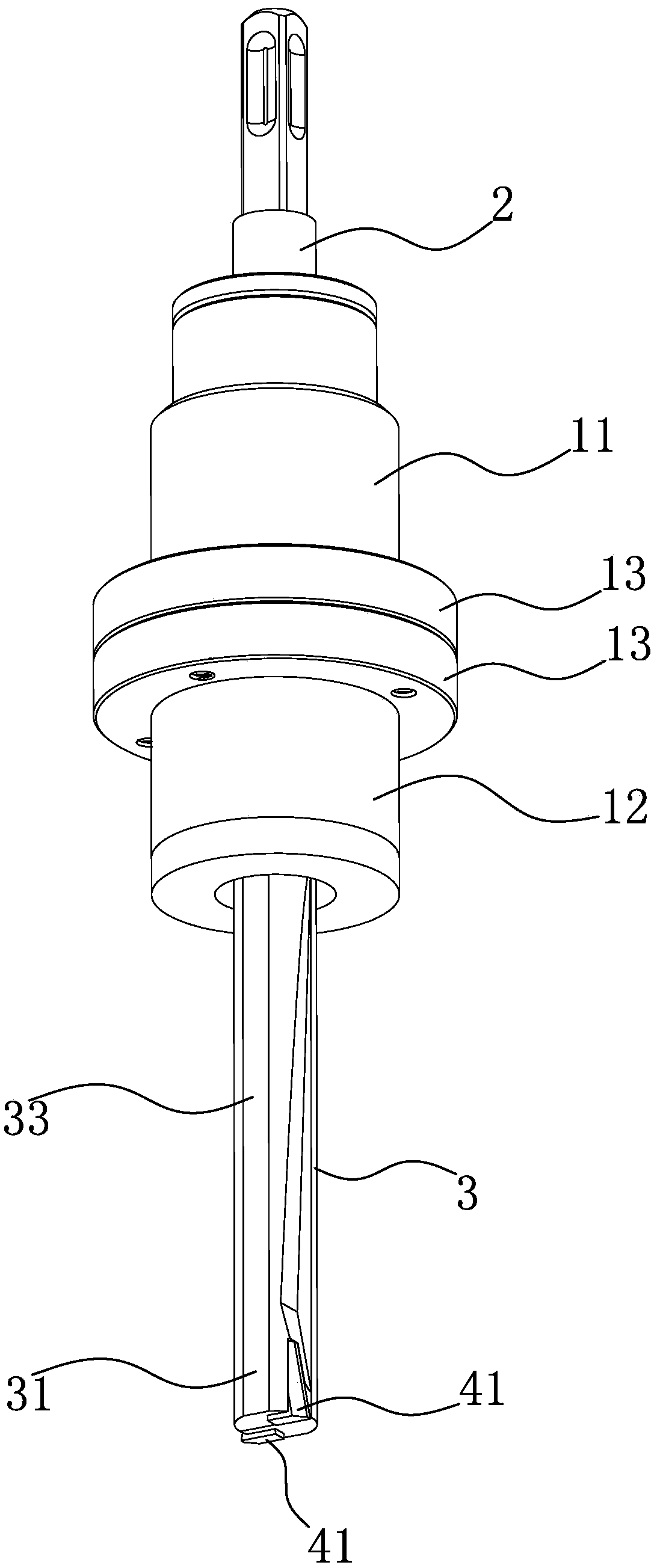

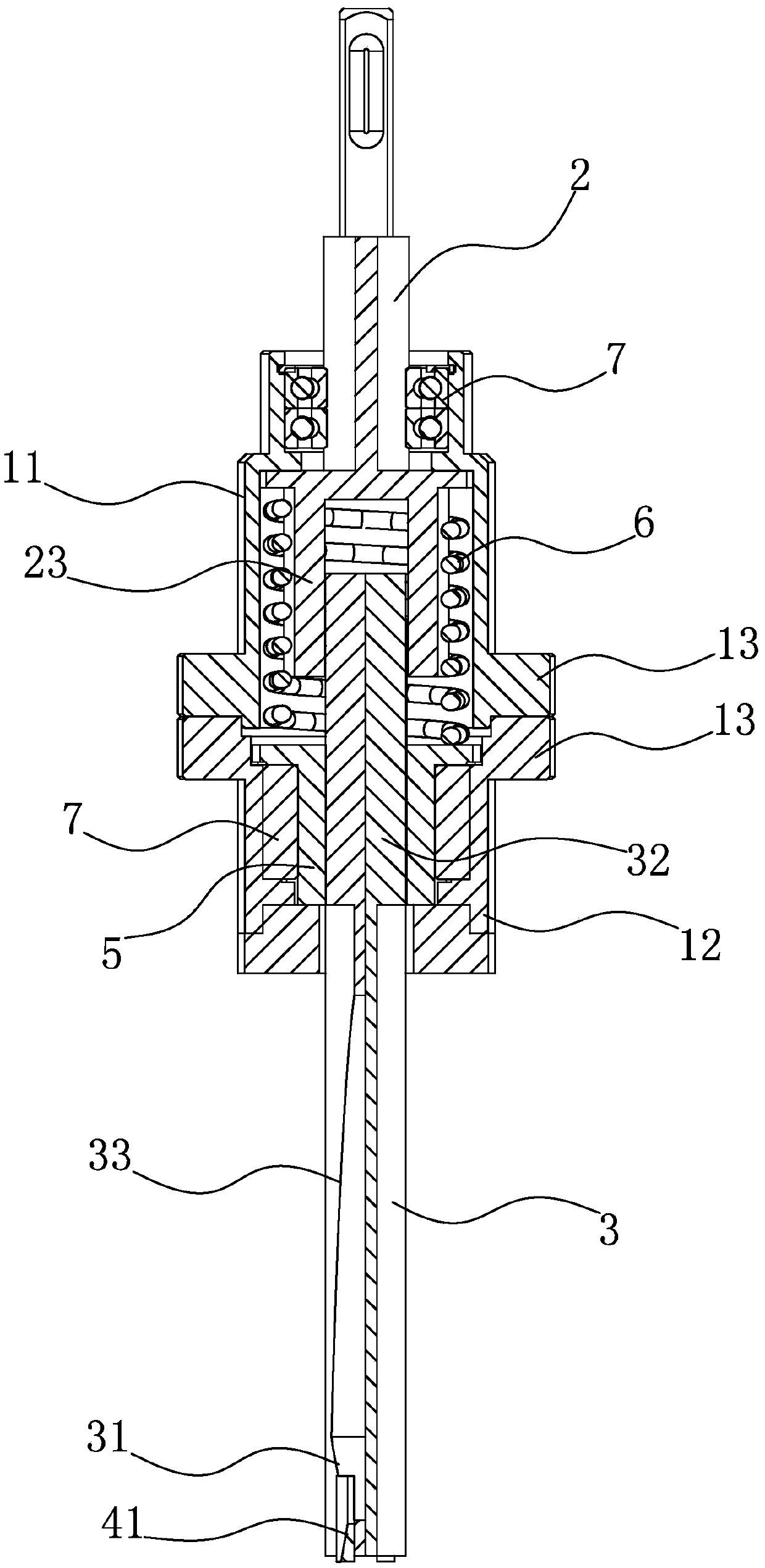

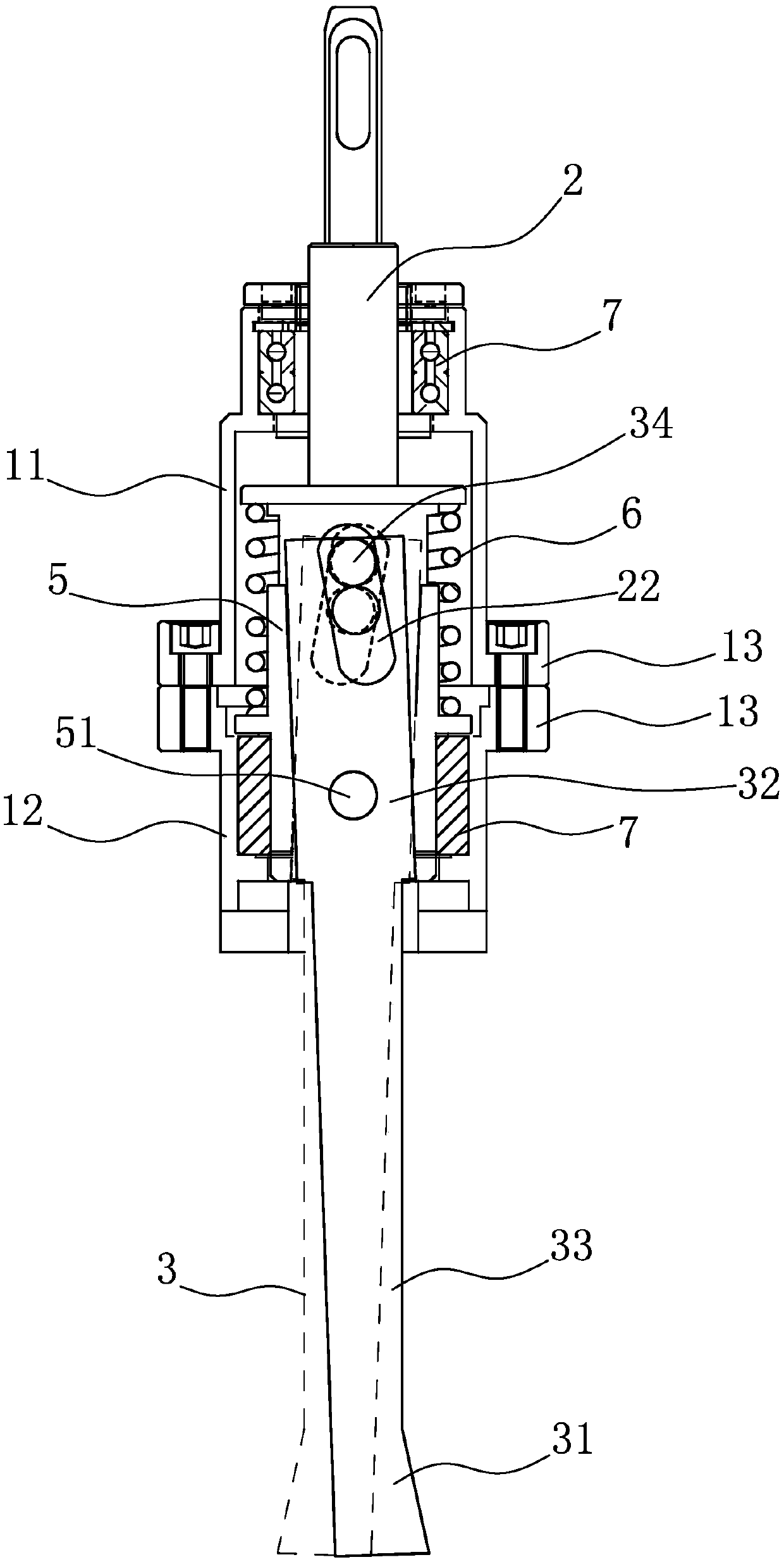

[0041] see Figure 1 to Figure 6According to the embodiment of the bottom reaming drill bit provided by the present invention, it includes a drill bushing, a drill rod and a drive shaft 2, the drill rod includes two hinged drill bars 3, and the drill bars 3 include an insertion part 33 and are arranged on the The fixing part 32 at one end of the insertion part 33 and the reaming part 31 provided at the other end of the insertion part 33, the reaming part 31 is located outside the drill sleeve, and the fixing part 32 is located at the In the drill sleeve, the fixed part 32 is connected to one end of the transmission shaft 2, and the transmission shaft 2 drives the two drill bars 3 to intersect and displace each other along the hinge part so that the two reaming parts 31 intersect and displace each other, so that The other end of the transmission shaft 2 is connected to an external power mechanism, and the ratio of the minimum thickness of the insertion portion 33 to the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com