Semi-outer coverage building type cast-in-place composite wall inorganic fire-proof self-insulation system

A self-insulation system and self-insulation technology, applied in the directions of heat preservation, fire prevention, and walls, can solve the problems of poor durability, poor fire safety, and poor performance against rainwater leakage, and achieve the effect of good energy saving and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

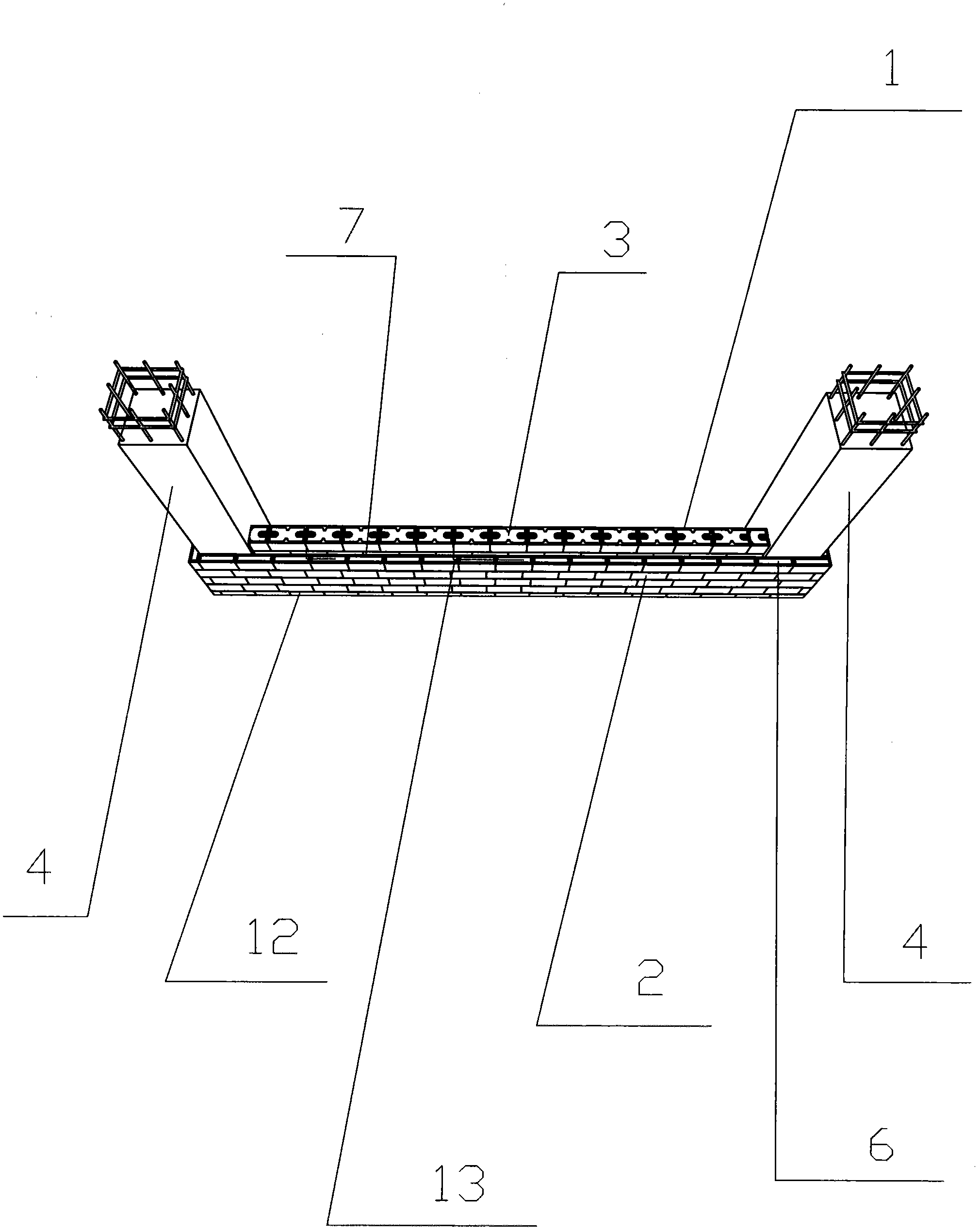

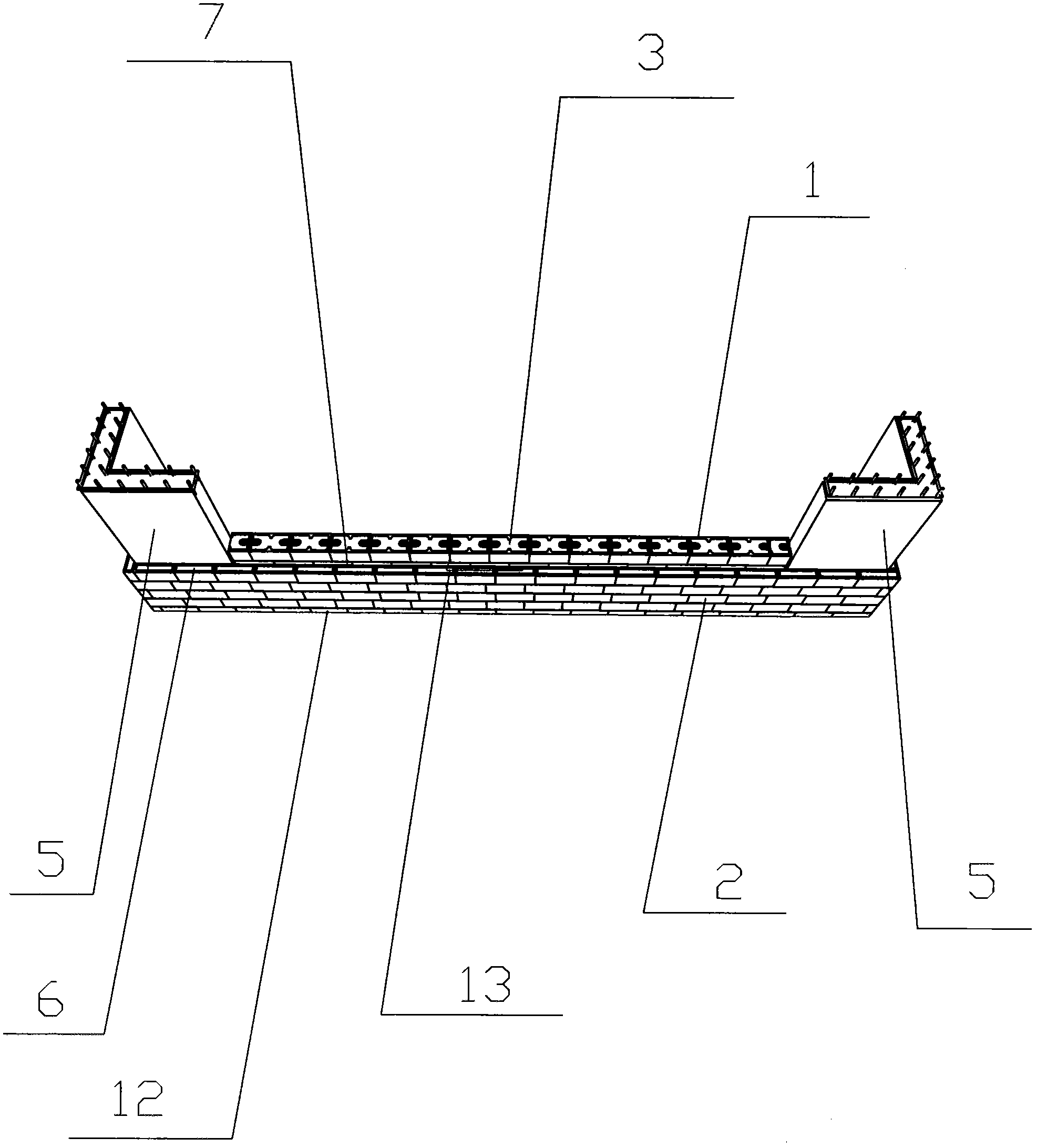

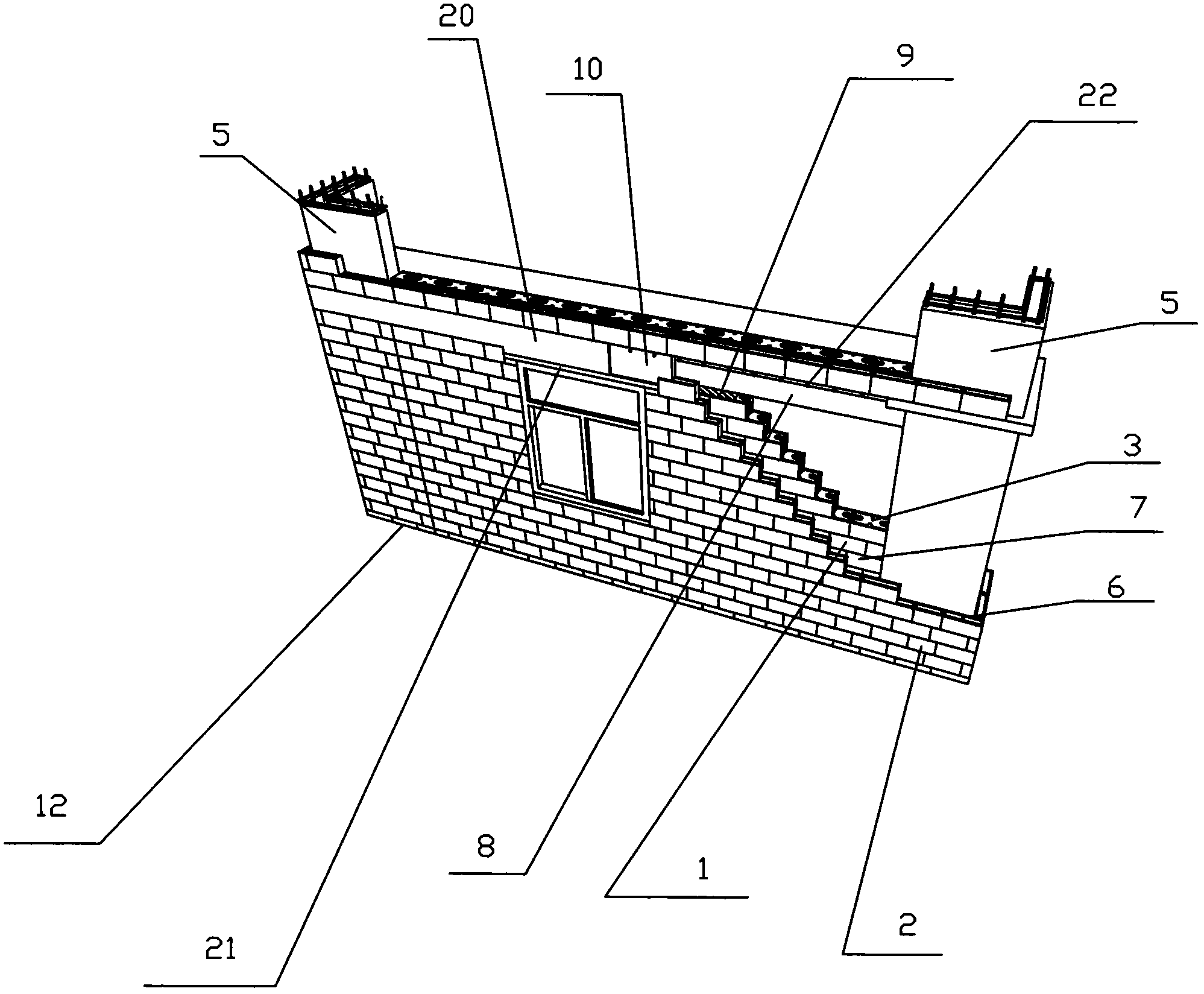

[0051] Such as Figure 9 As shown, a semi-outsourcing type cast-in-place composite wall inorganic fire-proof self-insulation system is characterized in that the semi-outsourcing type cast-in-place composite wall inorganic fire-proof self-insulation system includes A-type composite insulation block self-insulation wall 1. B-type composite thermal insulation block self-insulation wall 2. Inclined brick self-insulation wall and beam insulation body, insulation wall around doors and windows, and cast-in-place self-insulation wall at the upper end of the lintel and the top of the wall;

[0052]In this embodiment, the A-type composite thermal insulation block adopts a single-cavity H-core composite thermal insulation block 14, the B-type composite thermal insulation block adopts a single-cavity inline composite thermal insulation block 18, and the C-type composite thermal insulation block adopts a height lower than The composite thermal insulation block of the single-cavity one-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com