Precast pile post-grouting device and precast pile post-grouting process

A prefabricated pile and post-grouting technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of prolonging the pile driving period, difficult to popularize, affecting the friction resistance of the pile body, etc., so as to improve the pile driving efficiency and improve the Pile driving quality and the effect of improving stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

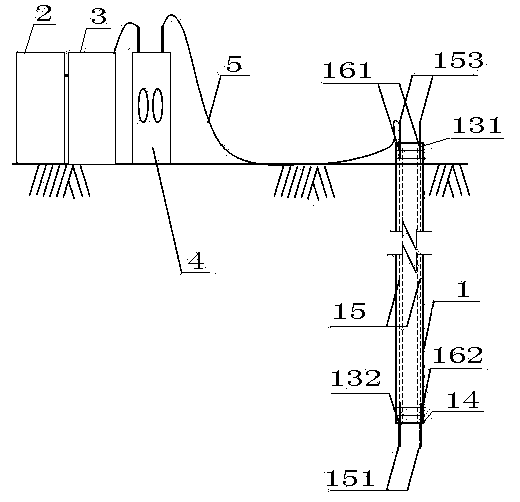

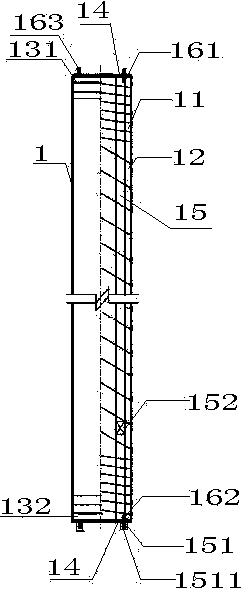

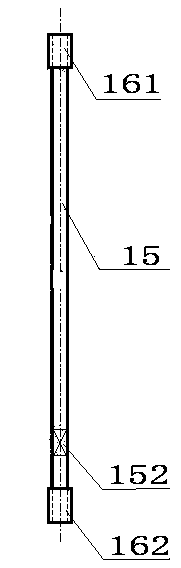

[0039] Embodiment 1: the prefabricated pile that adopts is pipe pile, as Image 6 As shown, the bolt hole 1321 and the bolt hole 1322 on the lower end plate 132 are the grouting holes 14, so that the grouting holes 14 are all on the same circumference, the same aperture, and symmetrically arranged to ensure that the pipe pile 1 maintains balance during the centrifugation process. Eccentric vibration does not occur. Such as Figure 7 As shown, two grouting pipes 15 are provided. The grouting pipes 15 are galvanized pipes with an inner diameter of Ф15 mm. The grouting device 151 is also provided with a protection device 1511. holes to facilitate the outflow of grout. The protection device 1511 is wrapped on the outside of the grouting device 151 and welded to the end of the grouting device 151. At the same time, the protection device 1511 is welded and fixed on the lower end plate 132 to prevent the grouting device 151 from being in the pile sinking process. destroyed in. Whe...

Embodiment 2

[0040] Embodiment 2: the prefabricated pile that adopts is pipe pile, as Figure 10 As shown, in the middle of the bolt holes 1321 and 1323, in the middle of the bolt holes 1322 and 1324, two grouting holes 14 are arranged symmetrically, and according to these two grouting holes 14, as Figure 11 As shown, two grouting pipes 15 are provided, and the grouting pipes 15 are galvanized pipes with an inner diameter of Ф15 mm. The grouting device 151 is also provided with a protection device 1511, and the protection device 1511 is provided with through holes on both side plates to facilitate the outflow of the slurry.

Embodiment 3

[0041] Embodiment 3: the prefabricated pile 1 that adopts is a hollow pipe pile, such as Figure 12 As shown, two grouting pipes 15 are arranged in the hollow of the prefabricated pile 1, and the lower end of the grouting pipe 15 is welded to the lower end plate 132. In order to withstand the resistance of the end soil, the connection part is strengthened, and a protective device 1511 is provided. The protection device 1511 is provided with through holes on both side plates to facilitate the outflow of slurry. The grouting pipe 15, the lower end plate 132 and the protection device 1511 are welded to each other. The diameter of the grouting pipe is usually a galvanized steel pipe with an inner diameter of Ф25mm as the grouting pipe. When the prefabricated piles have spud cans 6, this embodiment only takes the spud cans as an example, and other types of spud cans are implemented by reference. The spud cans 6 are fixed at the lower end plate 132, such as Figure 13 , Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com