Method for removing colloidal matters in tuna raw oil

A technology of tuna and crude oil, which is applied in food science, edible oil/fat, fat oil/fat refining, etc. It can solve the problems of dark color, low transparency of tuna oil, poor phosphoric acid degumming effect, etc., and achieve light color, good transparency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with specific embodiments.

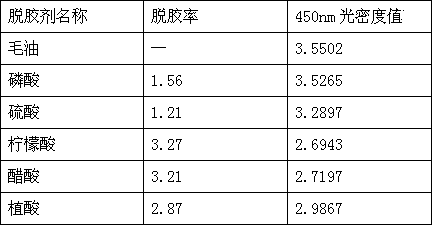

[0009] The present invention knows that the optimum temperature of degumming agent action is 50~65 ℃ through prior art, therefore adds 1% degumming agent in the tuna crude oil through pretreatment and impurity removal, between 50~65 ℃ and 50r Stir the crude oil at a speed of 25 min, then centrifuge at 5000r / min for 10 min, measure the color of the degummed oil, and calculate the degumming rate. The determination of the color is to take the crude tuna oil and scan it within the wavelength of 190-1100nm, and take the absorbance value at the maximum absorption wavelength as the color measurement value. The crude tuna oil was scanned within the wavelength of 190-1100nm, and it was found that there was a maximum absorption peak at 450nm. Degumming rate (%)=colloid precipitation after degumming (g) / sample amount of crude oil (g)×100%.

[0010] By using phosphoric acid, sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com