Automatic floating mechanism of screw locking machine

A floating mechanism and locking screw machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of machine structural parts and product damage, strong adverse reaction force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

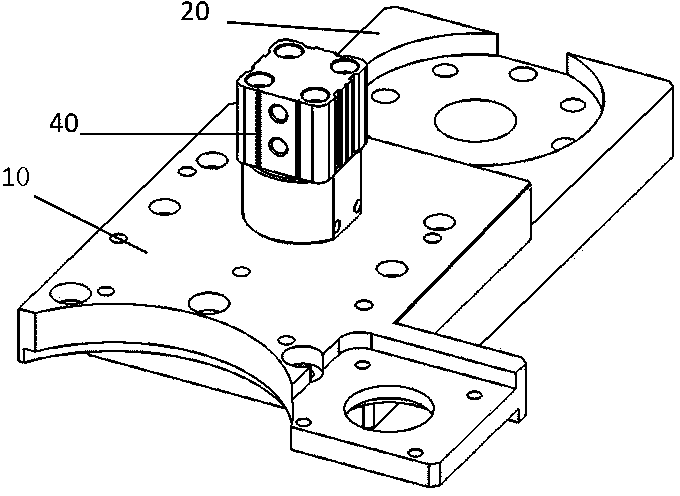

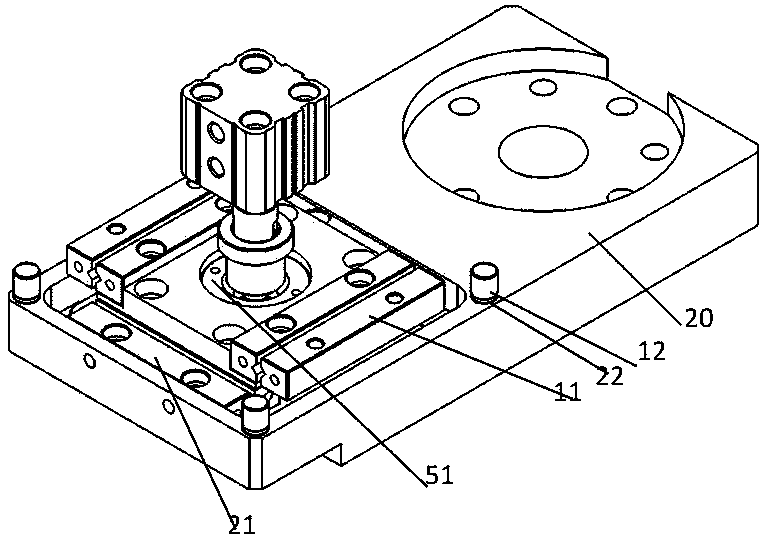

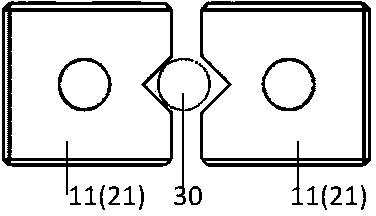

[0019] Example Figures 1 to 5 shown. A self-floating mechanism for locking screw machines, including a floating plate, a middle plate and a lower cover plate, an X-direction ball guide rail 11 is also included between the floating plate and the middle plate, and the X-direction ball guide rail 11 is connected to the floating There is also a Y-direction ball guide rail 21 between the lower cover board and the middle board, and the Y-direction ball guide rail 21 connects the lower cover board and the middle board. The X-direction ball guide 11 enables relative movement between the floating plate and the middle plate along the X-axis direction. The Y-direction ball guide rail 21 enables relative movement between the middle plate 50 and the lower cover plate 20 along the Y-axis direction. Therefore, the floating plate 10 can float in the horizontal direction relative to the lower cover plate 20 after being stressed.

[0020] The rail length is shorter than the slot that accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com