Special electric welding machine for welding stainless steel water tank

A technology of stainless steel, electric welding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

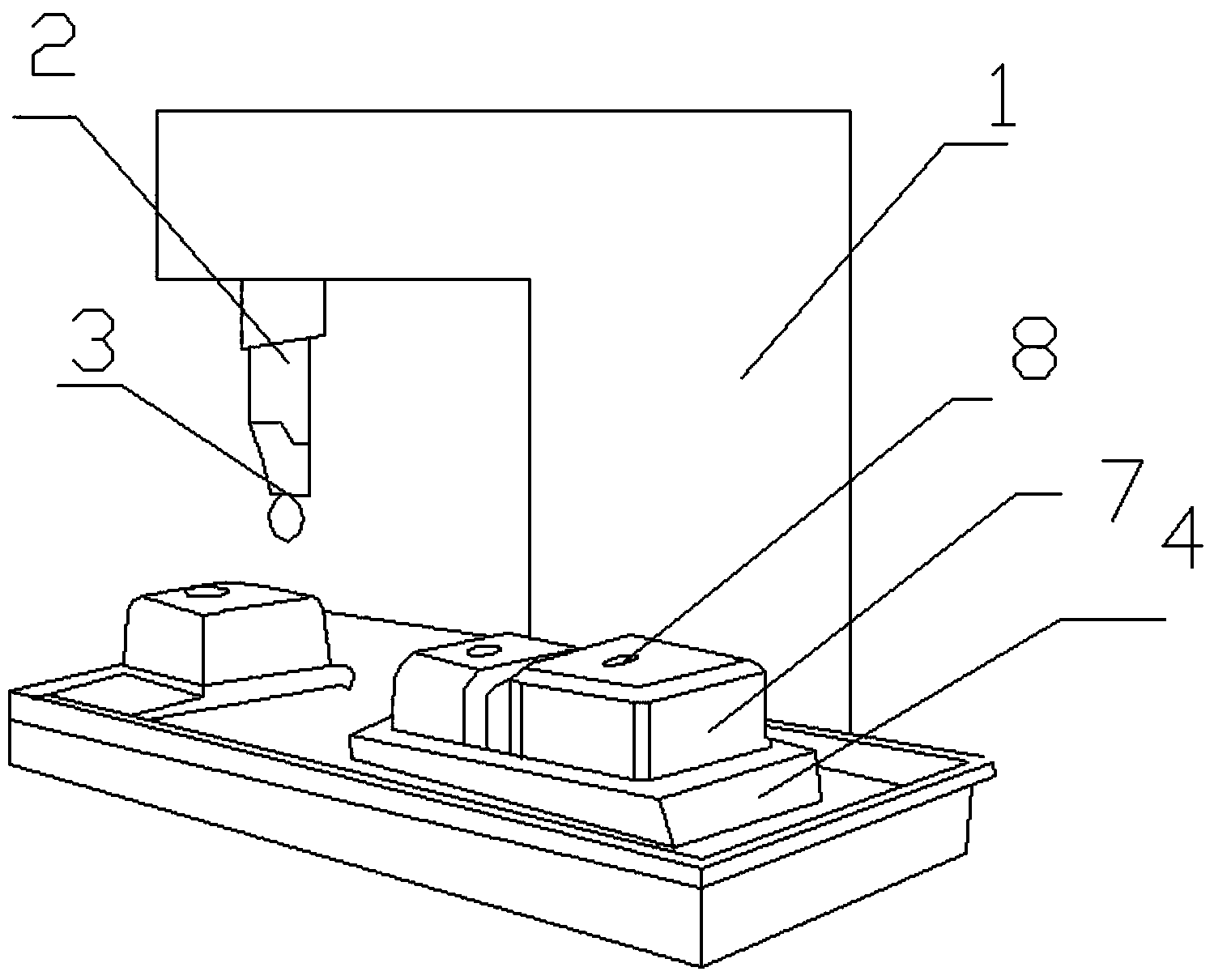

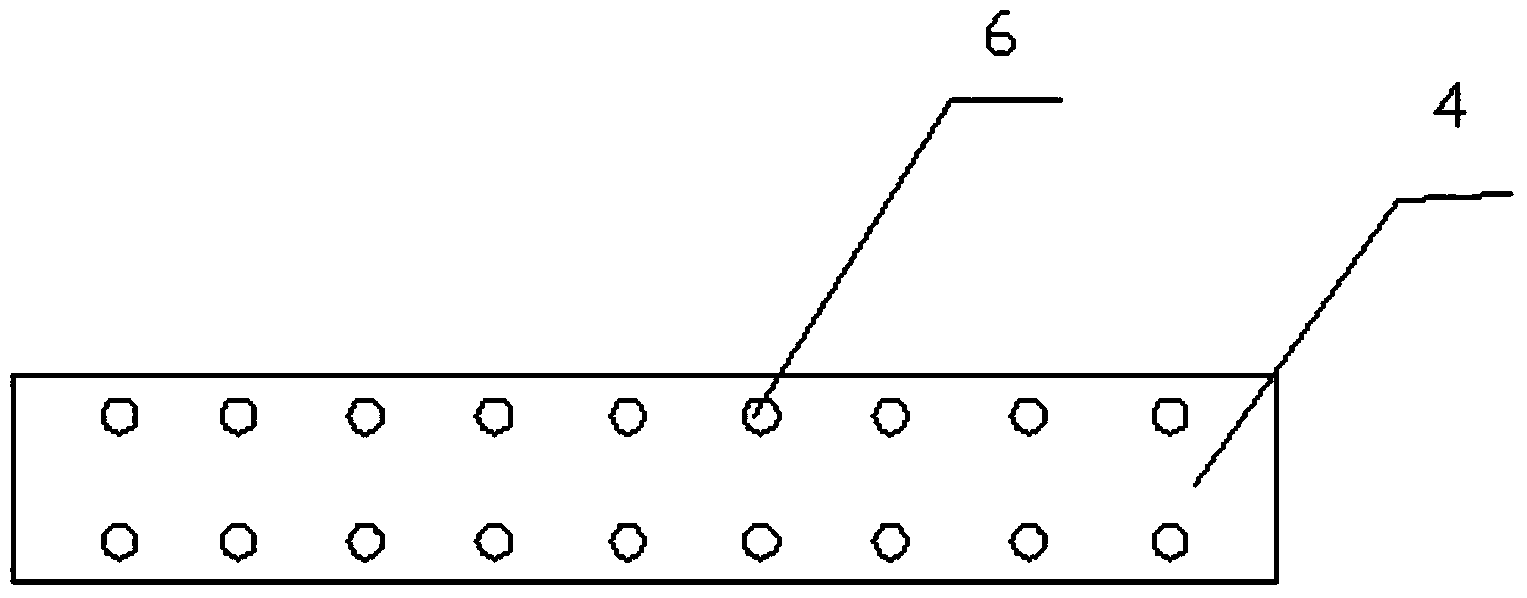

[0038] This embodiment includes a frame 1, a welding head connecting frame 2 and a welding head 3, and the welding head 3 is connected to the frame 1 through the welding head connecting frame 2, and also includes a workbench 4 and a positioning part 5, and the workbench 4 is fixed on the frame 1, the workbench 4 is located under the welding head 3, a plurality of positioning holes 6 are arranged on the workbench 4, the positioning part 5 is installed on the positioning holes 6 by bolts, and the positioning part 5 has at least two indivual. In this embodiment, a workbench and a positioning piece are added to the existing welding machine. The role of the positioning piece is to accurately position the stainless steel water tank body and panel to prevent the stainless steel tank body and panel from shifting, causing poor welding quality. When welding, put the panel on the workbench, position the tank body with a positioning piece, fix the tank body, and the tank body will not sha...

Embodiment 2

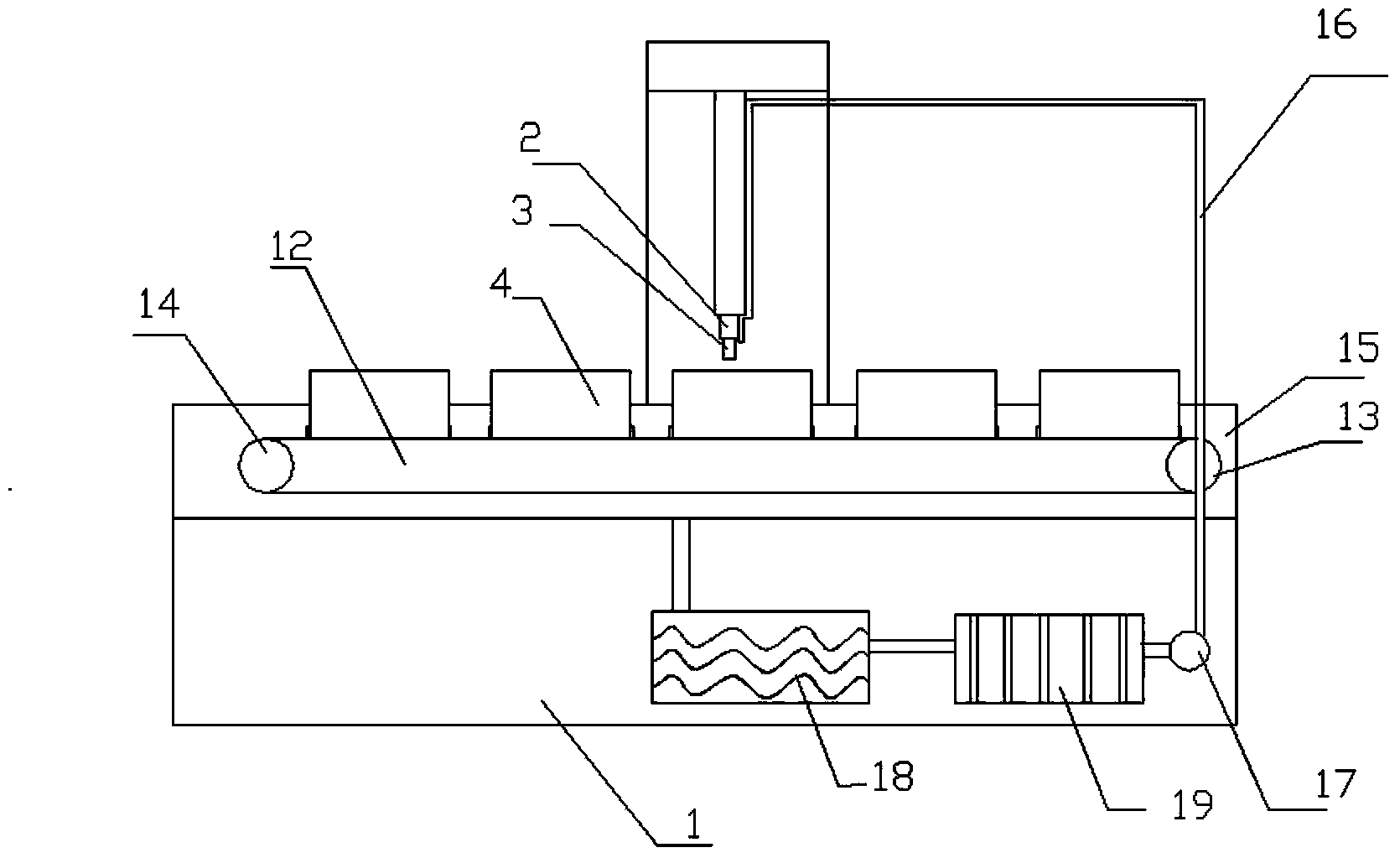

[0045] This embodiment includes a frame 1, a welding head connecting frame 2 and a welding head 3, and the welding head 3 is connected to the frame 1 through the welding head connecting frame 2, and also includes a workbench 4 and a positioning part 5, and the workbench 4 is fixed on the frame 1, the workbench 4 is located under the welding head 3, a plurality of positioning holes 6 are arranged on the workbench 4, the positioning part 5 is installed on the positioning holes 6 by bolts, and the positioning part 5 has at least two indivual.

[0046] The positioning part 5 of this embodiment is a cylindrical positioning part, which is fixed on the positioning hole 6 by bolts, and the diameter of the cylindrical positioning part matches the water leakage hole of the stainless steel tank body 7. The positioning part 5 of this embodiment is a cylindrical positioning part. When welding, the cylindrical positioning part is passed through the leakage hole 8 of the stainless steel wate...

Embodiment 3

[0052] This embodiment includes a frame 1, a welding head connecting frame 2 and a welding head 3, and the welding head 3 is connected to the frame 1 through the welding head connecting frame 2, and also includes a workbench 4 and a positioning part 5, and the workbench 4 is fixed on the frame 1, the workbench 4 is located under the welding head 3, a plurality of positioning holes 6 are arranged on the workbench 4, the positioning part 5 is installed on the positioning holes 6 by bolts, and the positioning part 5 has at least two indivual.

[0053] The positioning part 5 of this embodiment is an "L" shaped positioning part, including a mounting part 9 and a positioning part 10. The mounting part 9 is provided with a mounting hole 11. The positioning part 10 is perpendicular to the mounting part 9, and the bolt passes through the The mounting hole 11 and the positioning hole 6 fix the positioning member 5 on the workbench 4 .

[0054] There can be one or more workbenches in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com