Molding sand for casting elevator traction sheave and its special molding device

A technology of elevator traction and molding sand, which is applied in the directions of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of inconvenient core removal, unfavorable casting surface quality, damaged molding sand, etc., and achieves a simple and easy driving method. , The effect of shortening production time and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

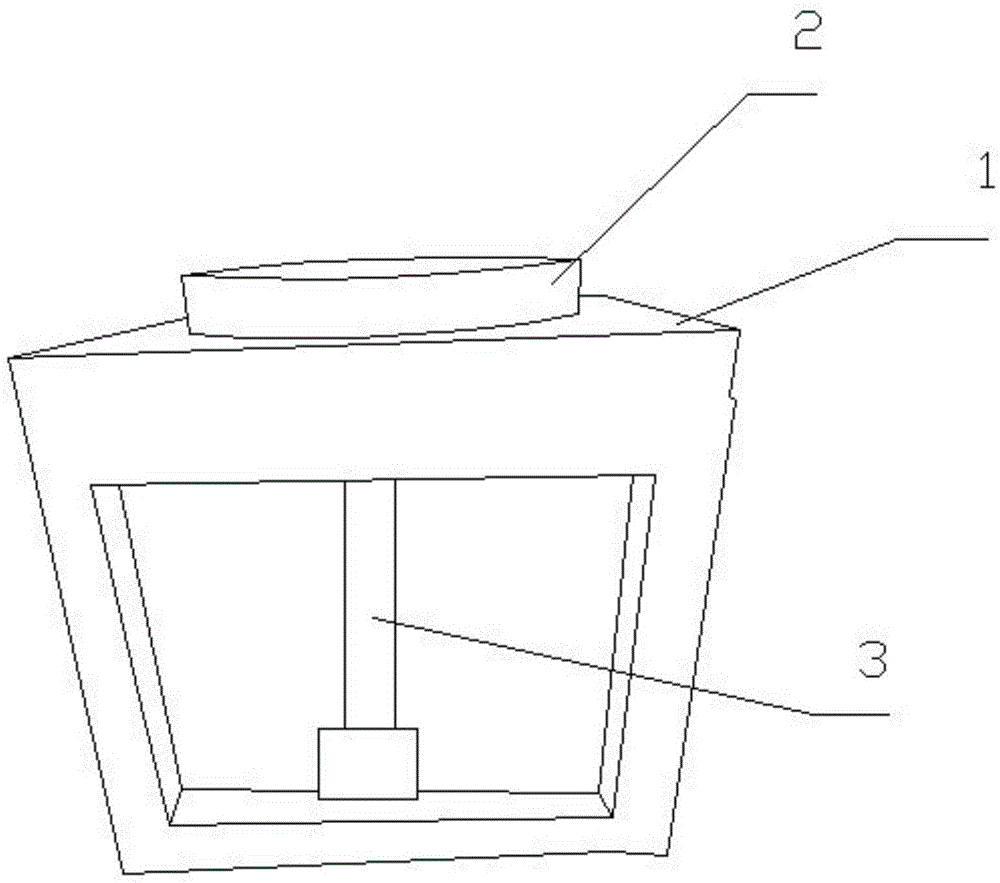

[0033] Such as figure 1 , Figure 4 and Figure 5 As shown, a kind of molding sand for casting elevator traction sheave, comprises three-layer structure, is divided into fine sand layer 13, middle sand layer 14 and coarse sand layer 15, and described fine sand layer is the innermost layer, and described middle The sand layer is the outer layer of the fine sand layer, the coarse sand layer is the outer layer of the middle sand layer, the fine sand layer is a sand layer made of sand with a fineness modulus less than 2.2, and the middle sand layer is composed of fineness modulus The sand layer is composed of sand with a modulus between 2.3, the coarse sand is a sand layer composed of sand with a fineness modulus between 3.1, and the thickness of the fine sand layer is between 30 mm.

[0034]This embodiment also provides a device for manufacturing the molding sand of this embodiment, including a workbench 1, a core 2 and a core control mechanism, a core groove is arranged in the...

Embodiment 2

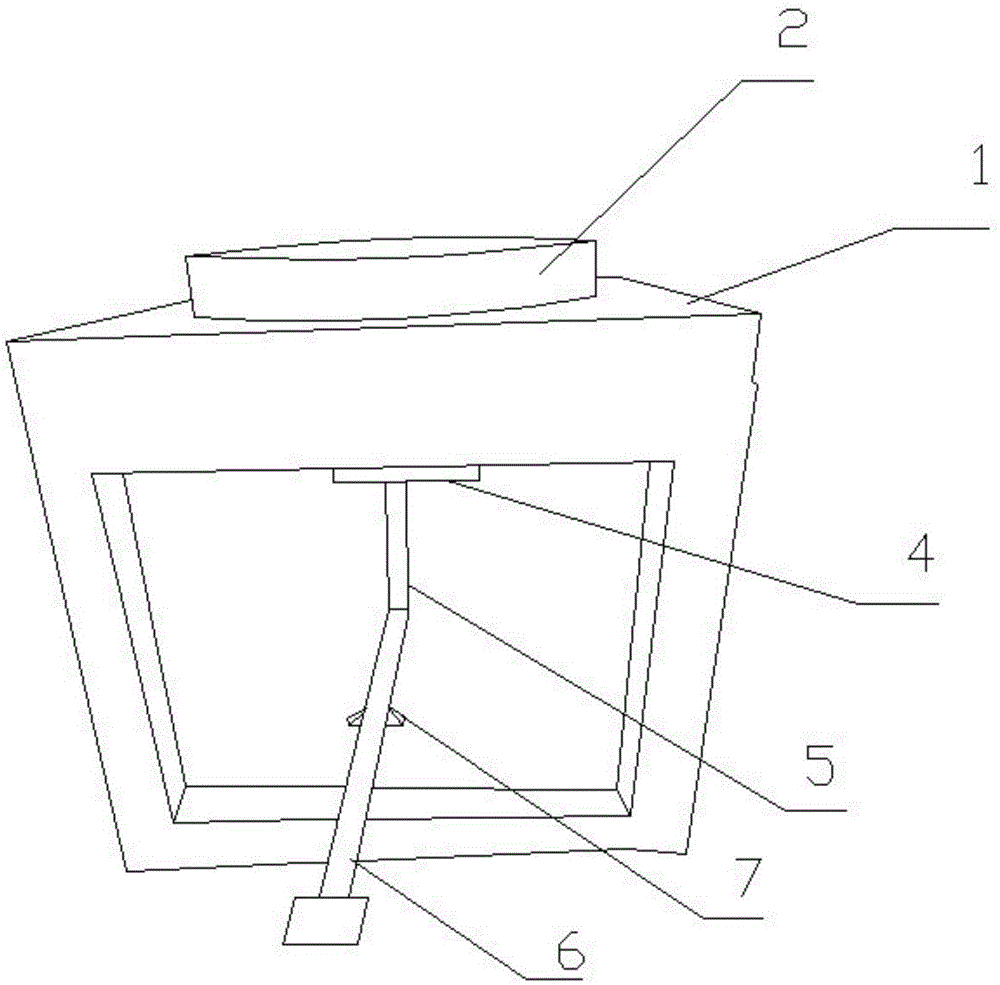

[0037] Such as figure 2 and Figure 5 As shown, a kind of molding sand for casting elevator traction sheave, comprises three-layer structure, is divided into fine sand layer 13, middle sand layer 14 and coarse sand layer 15, and described fine sand layer is the innermost layer, and described middle The sand layer is the outer layer of the fine sand layer, the coarse sand layer is the outer layer of the middle sand layer, the fine sand layer is a sand layer made of sand with a fineness modulus less than 2.2, and the middle sand layer is composed of fineness modulus The sand layer is composed of sand with a modulus between 2.5, the coarse sand is a sand layer composed of sand with a fineness modulus between 3.7, and the thickness of the fine sand layer is between 40mm.

[0038] This embodiment also provides a device for manufacturing the molding sand of this embodiment, including a workbench 1, a core 2 and a core control mechanism. The core control mechanism is used to contr...

Embodiment 3

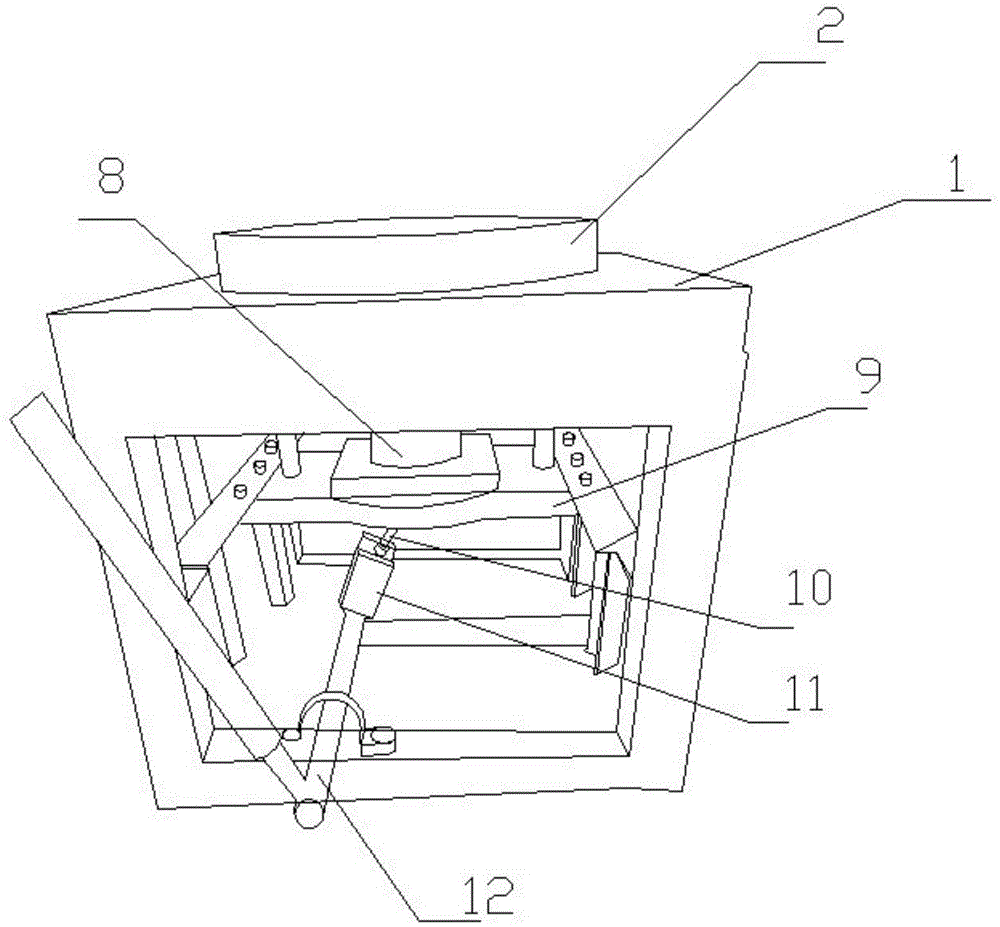

[0041] Such as image 3 and Figure 5 As shown, a kind of molding sand for casting elevator traction sheave, comprises three-layer structure, is divided into fine sand layer 13, middle sand layer 14 and coarse sand layer 15, and described fine sand layer is the innermost layer, and described middle The sand layer is the outer layer of the fine sand layer, the coarse sand layer is the outer layer of the middle sand layer, the fine sand layer is a sand layer made of sand with a fineness modulus less than 2.2, and the middle sand layer is composed of fineness modulus The sand layer is composed of sand with a modulus between 3.0, the coarse sand is a sand layer composed of sand with a fineness modulus between 3.4, and the thickness of the fine sand layer is between 50 mm.

[0042] This embodiment also provides a device for manufacturing the molding sand of this embodiment, including a workbench 1, a core 2 and a core control mechanism. The core control mechanism is used to contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com